Self-cleaning split mounting type secondary water supply tank

A secondary water supply and automatic cleaning technology, applied in water supply devices, water saving, cleaning hollow objects, etc., can solve the problems of secondary pollution of water quality, time-consuming, difficult cleaning, etc., to increase water supply time and increase cleaning time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those of ordinary skill in the art to which the invention pertains can easily implement these embodiments, but the present invention can also be implemented in various forms, Therefore, the present invention is not limited to the embodiments described hereinafter, and in addition, in order to describe the present invention more clearly, components not connected with the invention will be omitted from the drawings.

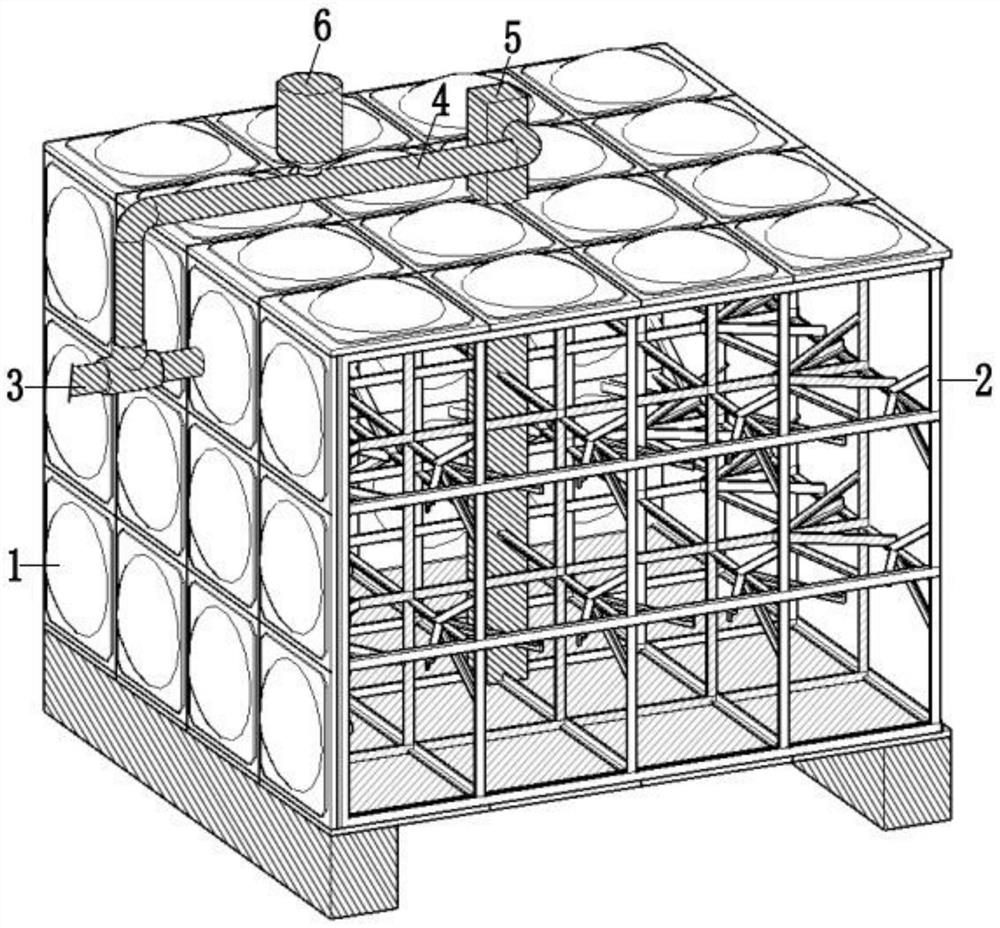

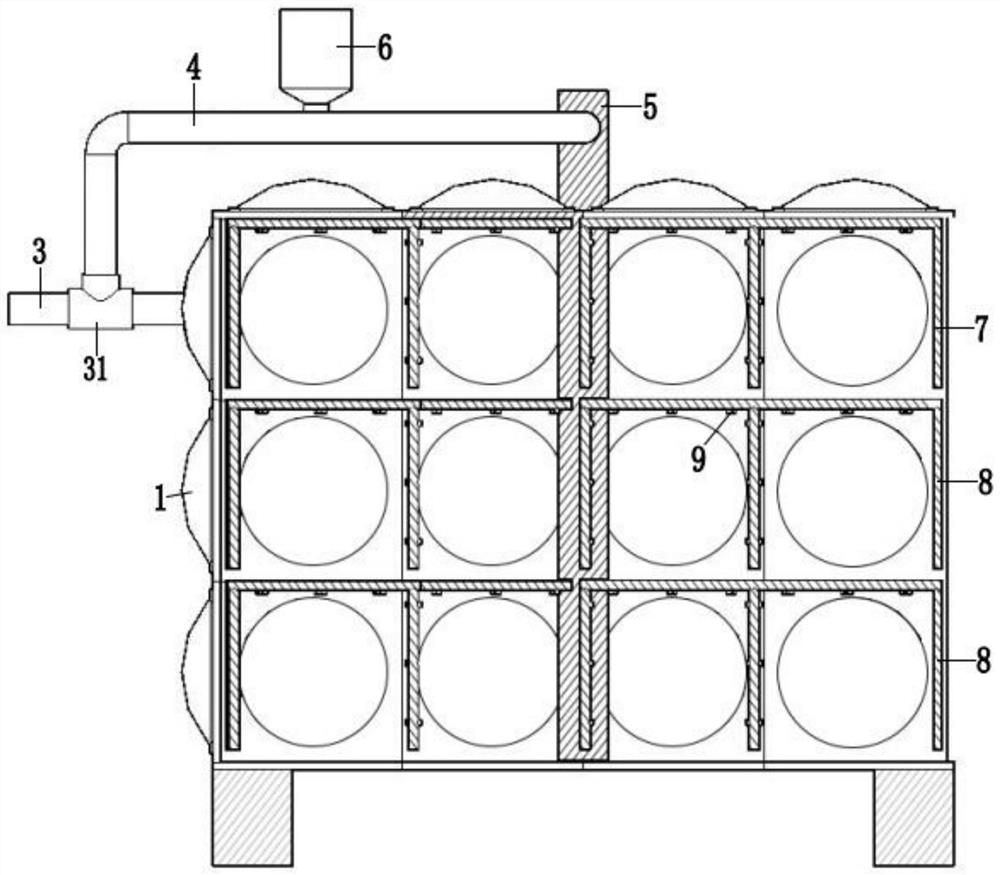

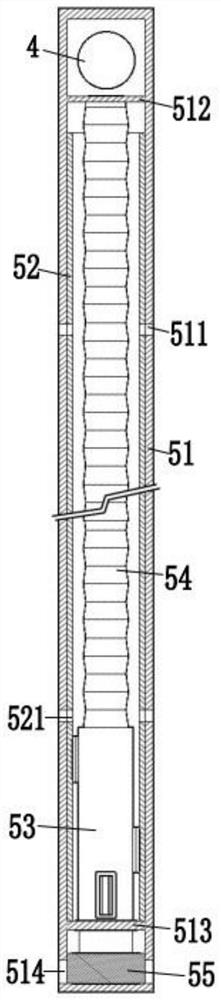

[0031] Such as figure 1 As shown, an self-cleaning assembled secondary water supply tank includes: cover plate 1, tie bars 2, water inlet pipe 1 3, water inlet pipe 2 4, water control mechanism 5, storage tank 6, pipe group 1 7, pipe Group 2 8, Nozzle 9;

[0032] The water tank is composed of the cover plates 1, for the convenience of description, the splicing mode of a plurality of the cover plates 1 is given as an example, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com