Fabricated airport boundary foundation formwork and using method

A prefabricated and formwork technology, which is applied in the fields of infrastructure engineering, formwork/formwork/work frame, formwork/formwork/work frame connection, etc. The construction process of the base and the ground beam is slow, and the construction efficiency is reduced, so as to achieve the effect of convenient fixing, fast supporting and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

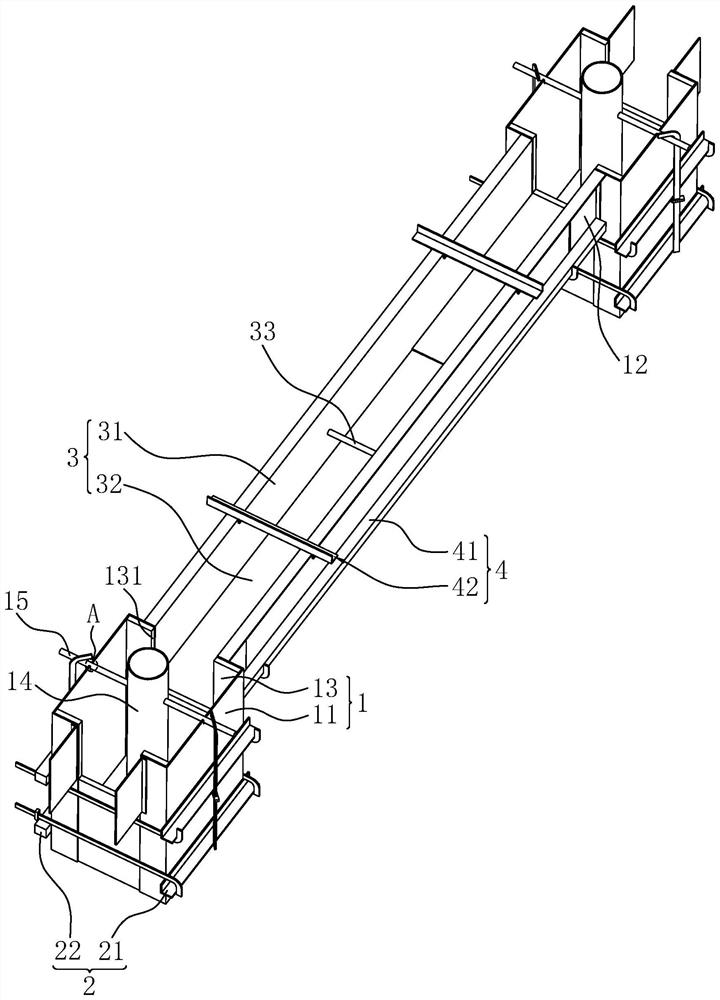

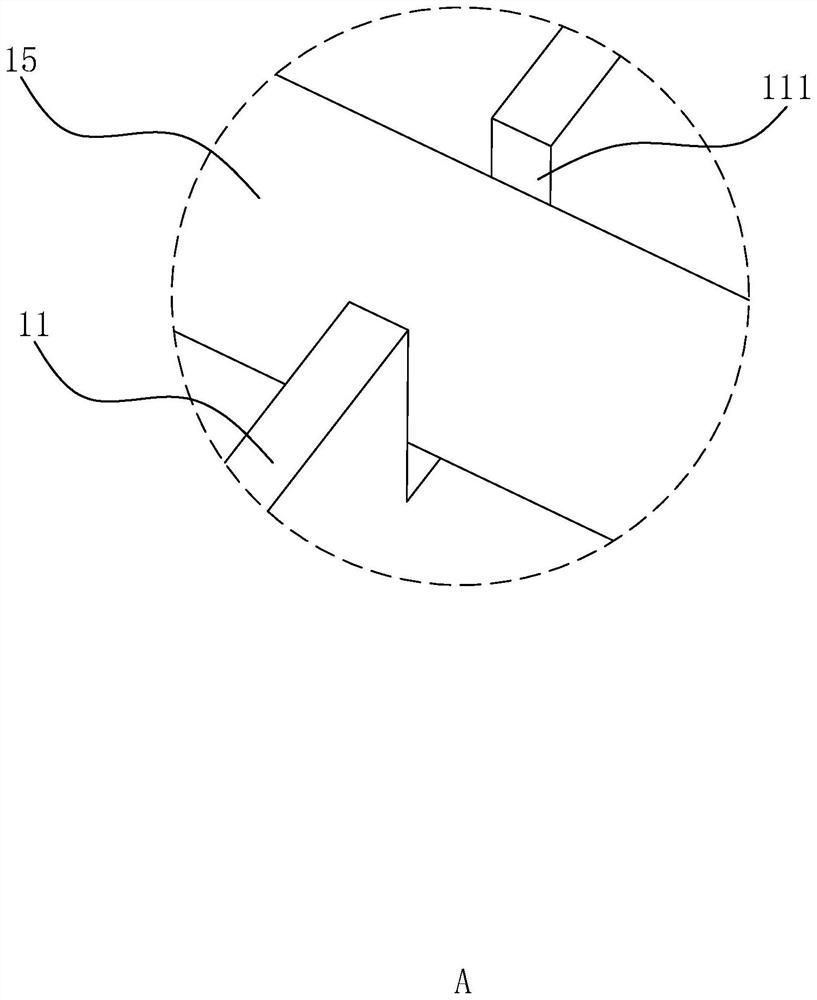

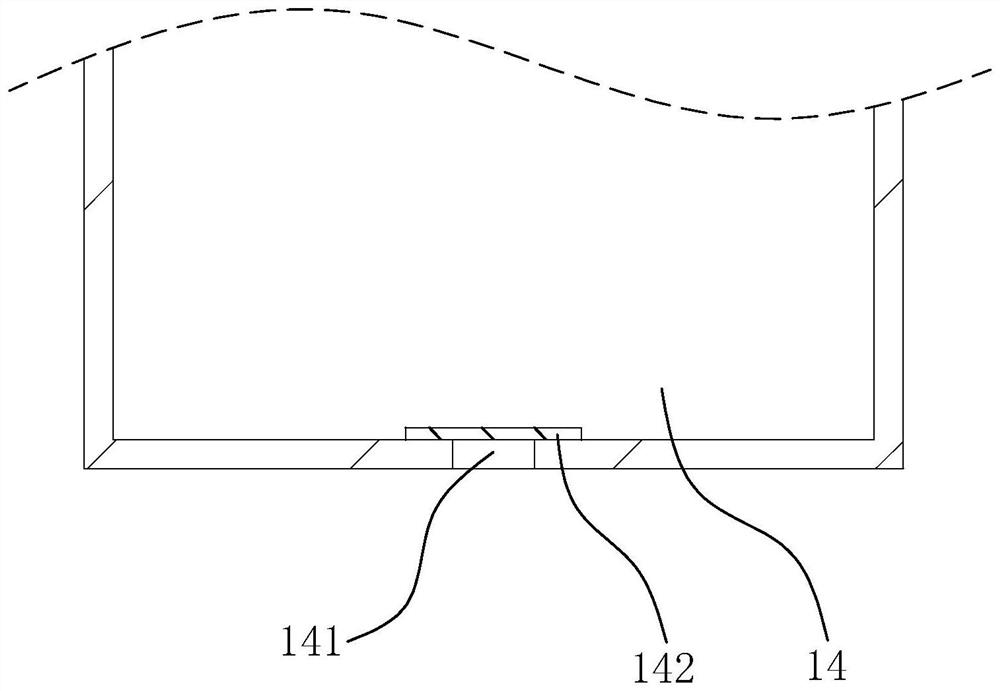

[0048] The following is combined with the attached Figure 1-5 Further elaboration of this application.

[0049] Embodiments of the present application disclose a prefabricated airport boundary foundation template. Reference Figure 1 , a kind of prefabricated airport boundary foundation template, set in the staggered arrangement of the foundation pit, the ground beam pit, including several staggered settings of the base template 1 and the ground beam template 3, the base template 1 is set in the foundation pit, the base template 1 is provided with a base fixed component 2, the ground beam template 3 is set in the ground beam pit, the ground beam formwork 3 is connected with the base template 1, the ground beam template 3 is provided with the ground beam fixed component 4, the base fixed component 2 is used to fix the base template 1, and the ground beam fixed component 4 is used to fix the ground beam template 3.

[0050] When used, a number of base templates 1 are assembled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com