Electromagnetic-permanent magnet multi-magnetic field composite high-speed electromagnetic valve with flexible damping

A high-speed solenoid valve, multi-magnetic field technology, applied in charging systems, fuel injection devices, machines/engines, etc., can solve the problems of large rebound degree and low dynamic response, and achieve the effect of reducing rebound and improving dynamic response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

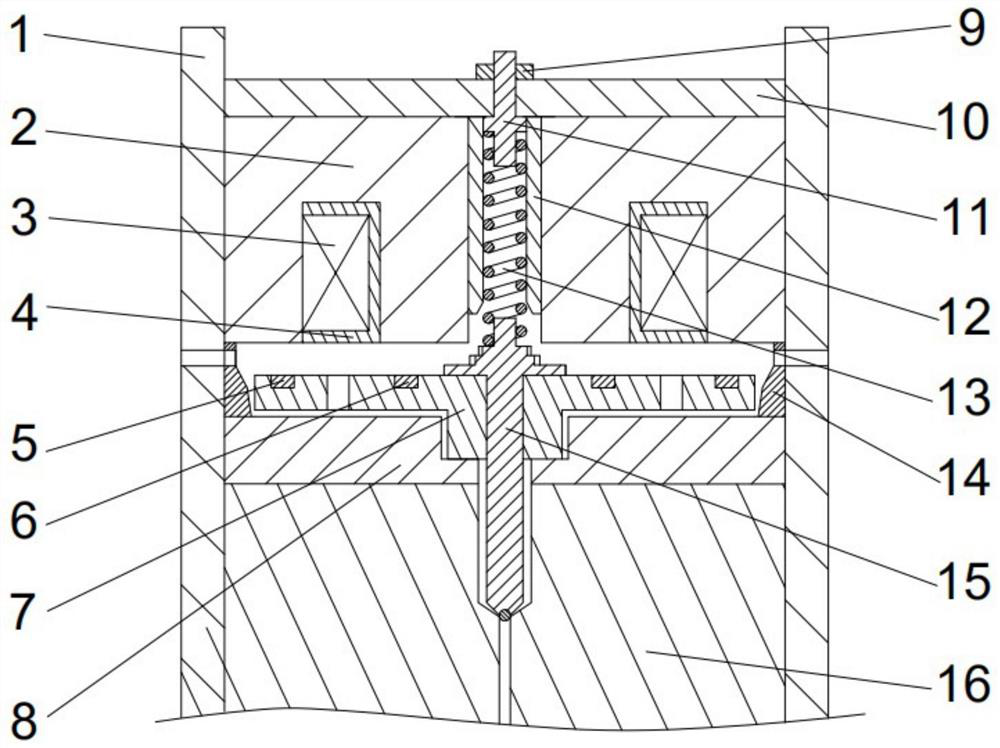

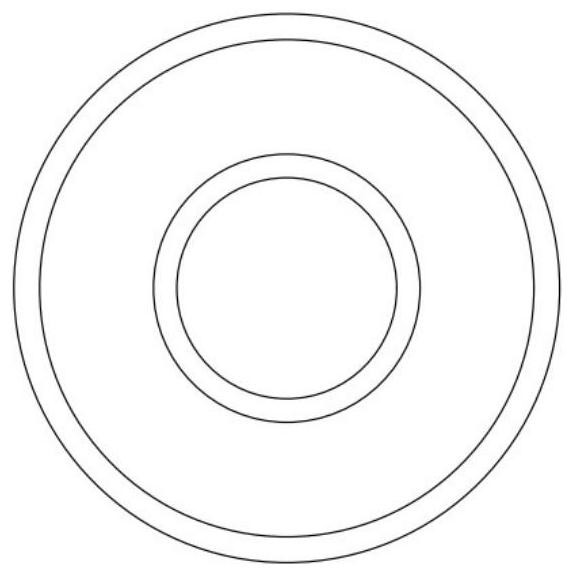

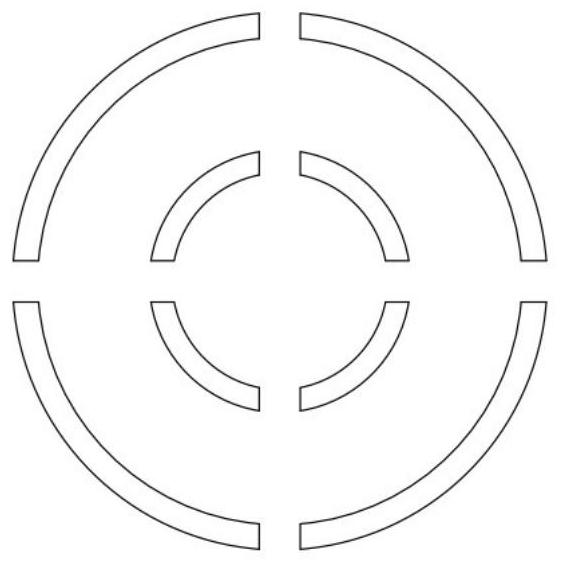

[0026] combine Figure 1-5 The composition of the present invention includes a housing 1, an iron core 2, a coil 3, a coil bobbin 4, an outer permanent magnet ring 5, an inner permanent magnet ring 6, an armature 7, an armature buffer seat 8, an adjusting nut 9, a fixing nut 10, a cross Type bolt 11, spring guide sleeve 12, armature return spring 13, armature lift adjustment ring 14, valve stem 15, injector body 16. The top of the housing 1 is provided with a fixing nut 10, and the iron core 2 is provided with an annular groove to form the main magnetic pole 18 and the auxiliary magnetic pole 20 of the iron core. The width and axial height of the groove are equal to or less than the depth of the annular groove of the iron core. The coil bobbin 4 is embedded in the annular groove of the iron core. There is an axial center through hole in the middle of the iron cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com