Permanent magnet-electromagnetic cooperative coupling high-speed electromagnetic valve with high dynamic response and low rebound

A high-speed solenoid valve and low rebound technology, which is applied in combustion engines, engine components, machines/engines, etc., can solve the problems that the solenoid valve cannot be opened and closed, hinders the rapid increase of the electromagnetic force of the solenoid valve, and the large Joule heat of the excitation coil. , to achieve the effects of improving the dynamic response, accelerating the seat of the armature, and accelerating the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below in conjunction with the accompanying drawings:

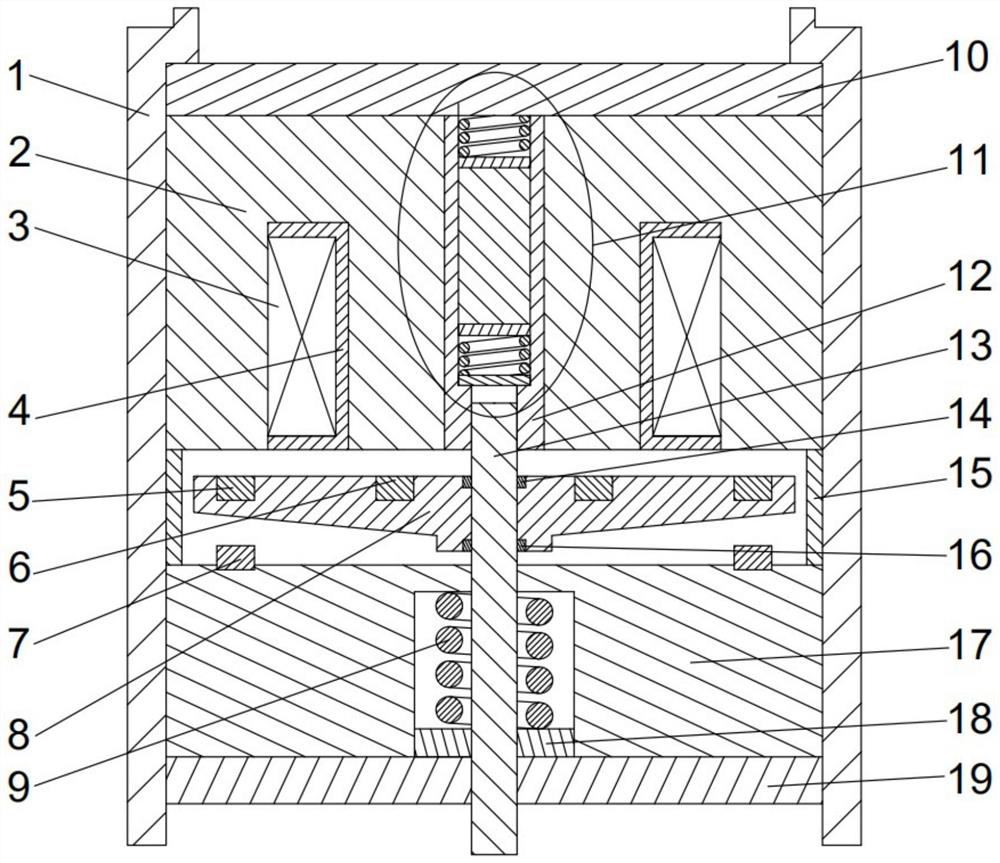

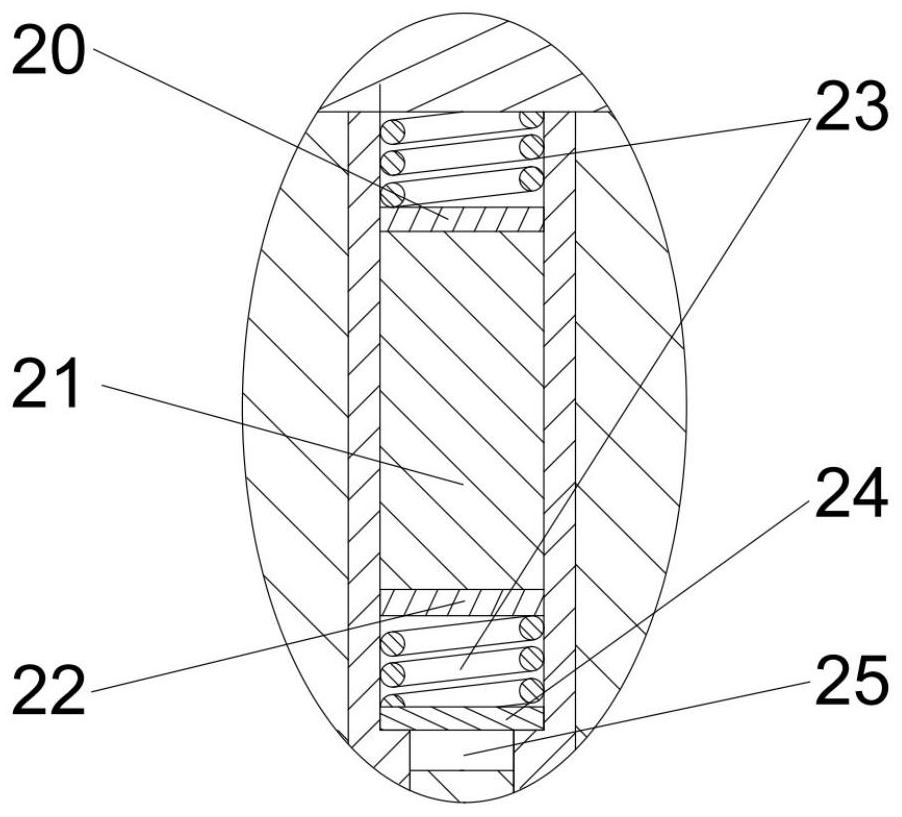

[0027] combine Figure 1-6 , the composition of the present invention includes shell 1, iron core 2, coil 3, coil bobbin 4, outer permanent magnet ring 5, inner permanent magnet ring 6, buffer permanent magnet ring 7, armature 8, armature return spring 9, fixing nut 10 , giant magnetostrictive assembly 11, spring limit sleeve 12, valve stem 13, armature upper snap ring 14, armature lift adjustment ring 15, armature lower snap ring 16, return spring cavity 17, return spring washer 18, tightening Secure the nut 19. The top and bottom of the casing 1 are respectively provided with a fixing nut 10 and a tightening nut 19, and an annular groove is formed on the iron core 2 to form the main magnetic pole and the auxiliary magnetic pole of the iron core. The coil 3 is wound in the bobbin 4, the radial width of the bobbin 4 is equal to the width of the annular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com