Rotor assembly, motor and compressor

A compressor and rotor technology, applied in the field of compressors, can solve the problems of increasing the oil output of the compressor and poor oil separation effect, and achieve the effects of reducing the oil output, increasing the flow path, and improving the running performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

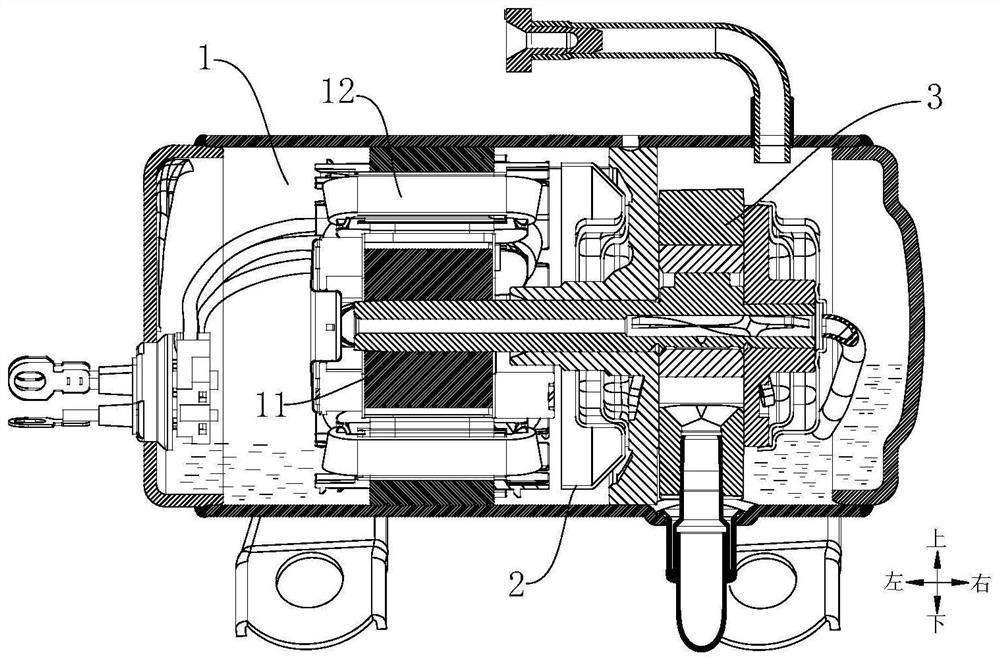

[0036] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

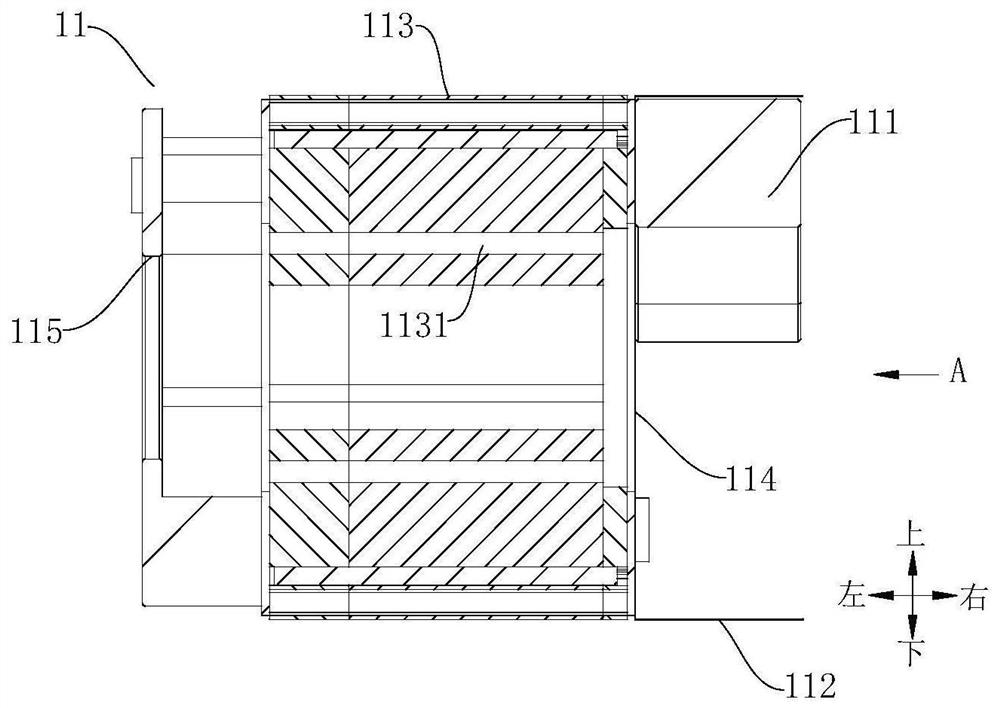

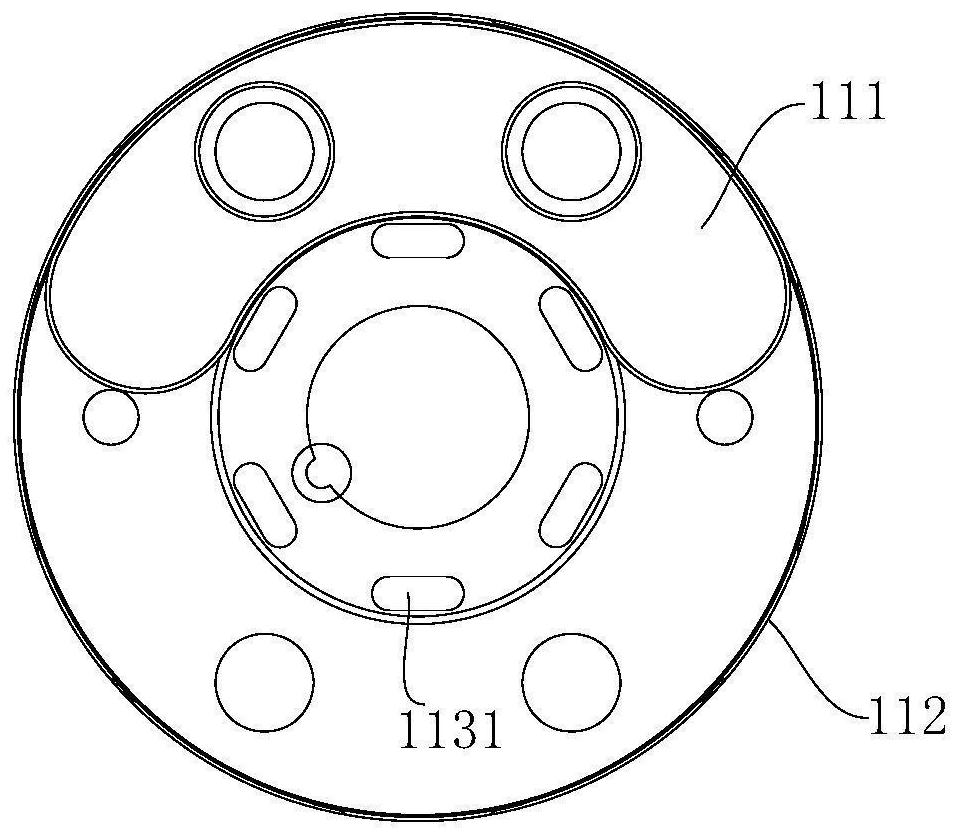

[0037] Such as figure 1 As shown, the rotor assembly 11 according to the embodiment of the present invention includes a rotor body 113 , a balance weight 111 , an enclosure 112 and a fan 115 . The balance weight 111 , the enclosure 112 and the fan 115 are all arranged on the rotor main body 113 . The fan 115, the rotor main body 113, and the balance weight 111 are along the first direction (such as figure 1 The left-to-right direction) are arranged in sequence.

[0038] The rotor main body 113 is provided with a plurality of ventilation holes 1131 , and the plurality of ventilation holes 1131 extend along the axial direction of the rotor main body 113 to penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com