Wall-hanging stove control method, device and equipment and computer readable storage medium

A control method and wall-hung boiler technology, applied in the field of wall-hung boiler control methods, devices, equipment, and computer-readable storage media, capable of solving the problems of failure to start, false alarms of the wall-hung boiler, and inability of the wall-hung boiler to distinguish between low-voltage working conditions and blocked working conditions conditions and other issues to achieve the effect of avoiding false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

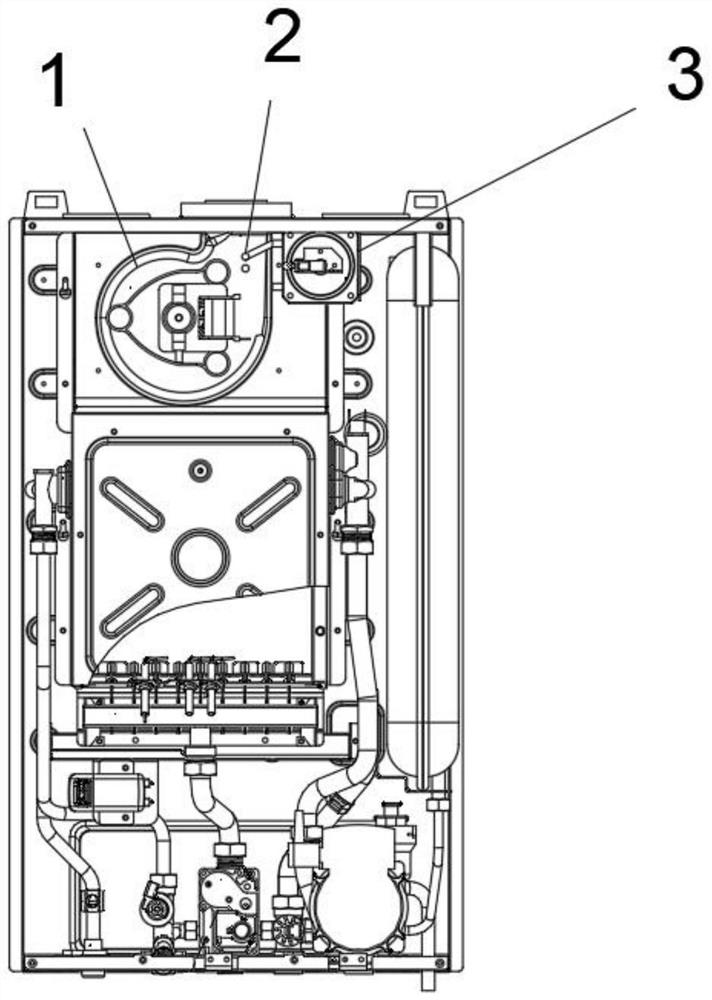

[0059] This embodiment provides a control method for a wall-hung boiler, which is used to control a wall-hung boiler system, such as figure 1 As shown, the wall-hung boiler system includes a fan 1 , a Venturi tube 2 and a wind pressure sensor 3 .

[0060] After the fan 1 is powered on, the airflow is generated, and the size of the airflow is controlled by giving the fan 1 different working voltages. The venturi tube 2 is connected to the fan 1, and the airflow passes through the venturi tube 2. The wind pressure sensor 3 is used to obtain the venturi tube 2 The wind pressure value in , the wind pressure value is set as the actual wind pressure value of the wall-hung boiler system. It can be understood that different actual wind pressure values will be measured when the fan 1 is given different working voltages.

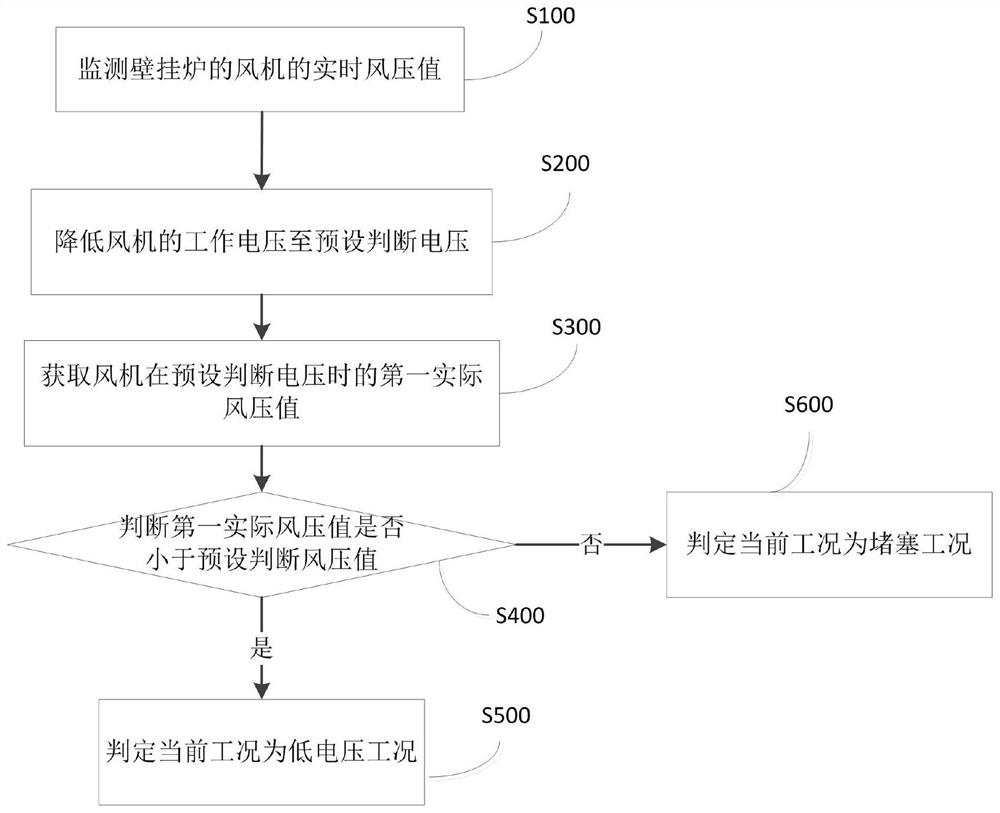

[0061] figure 2 is a flow chart of the control method provided by this embodiment, such as figure 2 As shown, the control method includes: step S100, monitoring...

Embodiment 2

[0077] This embodiment provides a control method for a wall-hung boiler, which is used to control a wall-hung boiler system, such as figure 1 As shown, the wall-hung boiler system includes a fan 1 , a Venturi tube 2 and a wind pressure sensor 3 .

[0078] After the fan 1 is powered on, the airflow is generated, and the size of the airflow is controlled by giving the fan 1 different working voltages. The venturi tube 2 is connected to the fan 1, and the airflow passes through the venturi tube 2. The wind pressure sensor 3 is used to obtain the venturi tube 2 The wind pressure value in , the wind pressure value is set as the actual wind pressure value of the wall-hung boiler system. It can be understood that different actual wind pressure values will be measured when the fan 1 is given different working voltages.

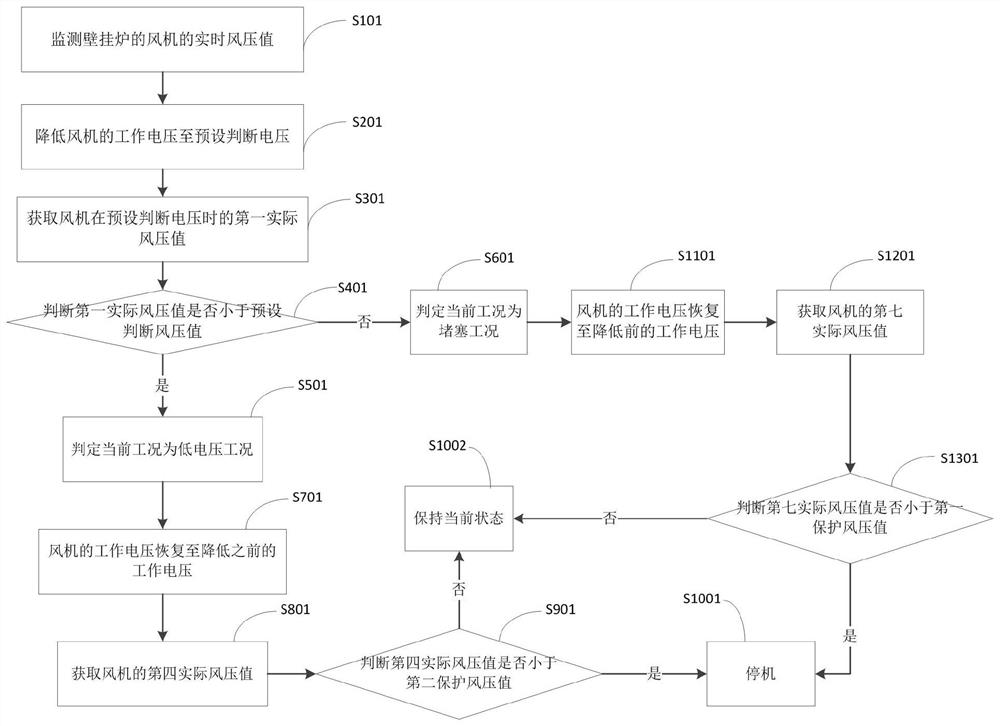

[0079] image 3 is a flow chart of the control method provided by this embodiment, such as image 3 as shown,

[0080] The control method includes: step S101, mo...

Embodiment 3

[0103] This embodiment provides a control device for a wall-hung boiler, which is used to control a wall-hung boiler system.

[0104] Such as figure 1 As shown, the wall-hung boiler system includes a fan 1 , a Venturi tube 2 and a wind pressure sensor 3 .

[0105] After the fan 1 is powered on, the airflow is generated, and the size of the airflow is controlled by giving the fan 1 different working voltages. The venturi tube 2 is connected to the fan 1, and the airflow passes through the venturi tube 2. The wind pressure sensor 3 is used to obtain the venturi tube 2 The wind pressure value in , the wind pressure value is set as the actual wind pressure value of the wall-hung boiler system. It can be understood that different wind pressure values will be measured when the fan 1 is given different working voltages.

[0106] Such as Figure 4 , the control device of the wall-hung boiler includes a wind pressure value detection module 101 , a voltage adjustment module 102 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com