Object simulation module

A simulation and object technology, applied in simulators, program control, instruments, etc., can solve problems such as difficulty in verifying the stability of control algorithms, low flexibility, and inability to output process data, achieving high cost performance, rich communication interfaces, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

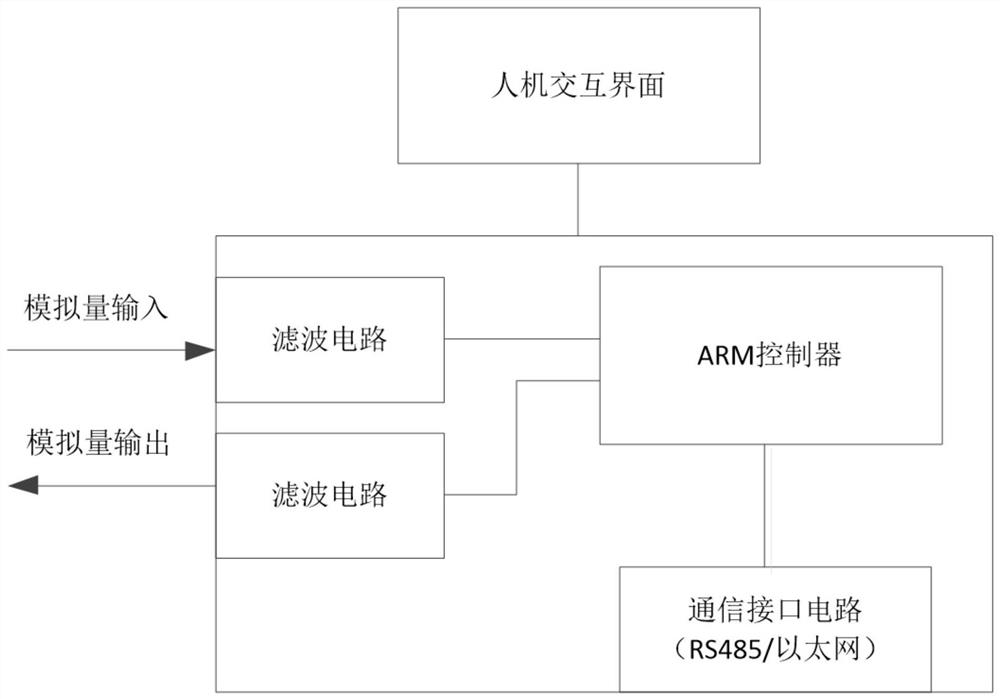

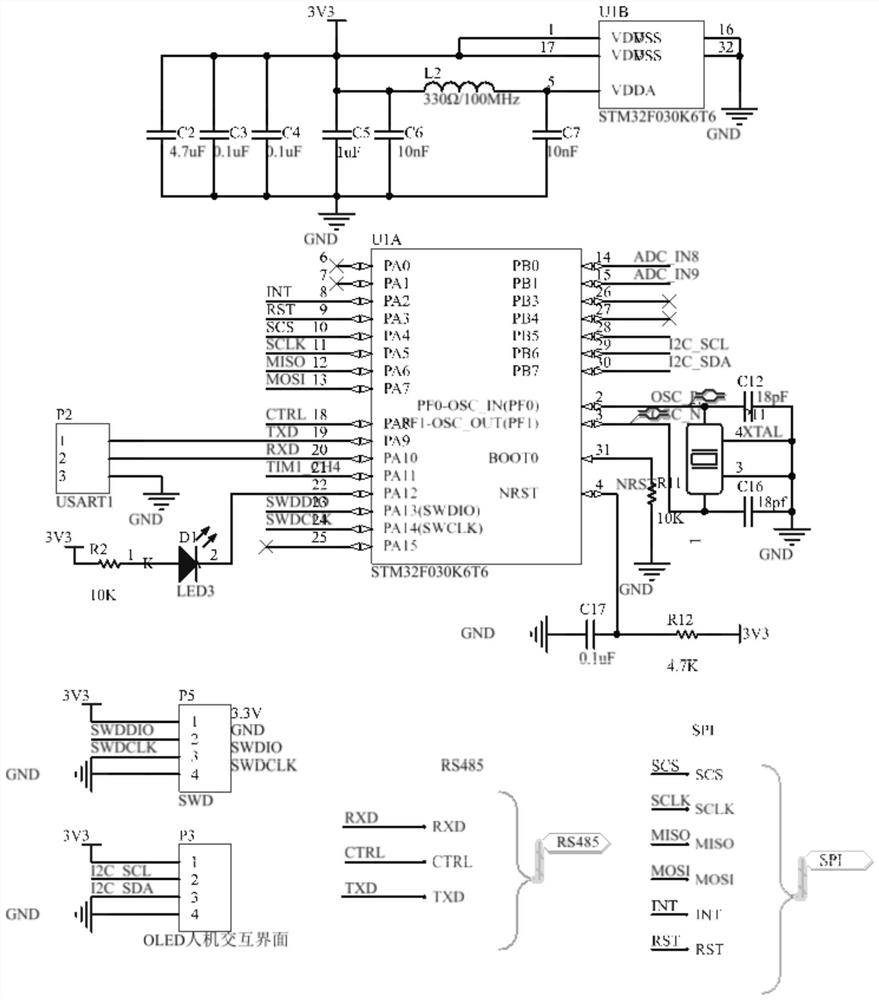

[0034] An object simulation module, see Figure 1-Figure 6 , which includes a control circuit and a human-computer interaction part;

[0035] The control circuit includes an ARM controller module, an analog input sampling circuit, an analog output circuit, and a communication interface circuit. The ARM controller module is used to collect external input analog signals, perform mathematical model calculations, and output corresponding proportional PWM signals. Provide communication interface for upper computer communication;

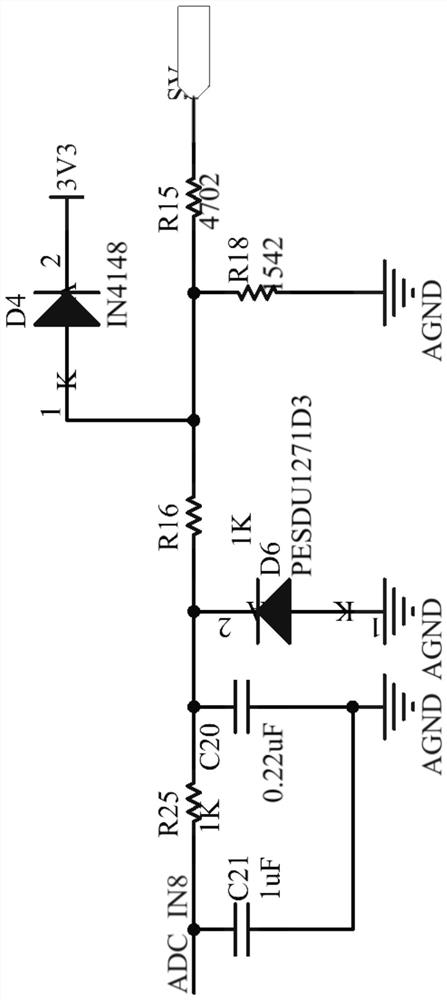

[0036] The analog input sampling circuit is used to receive the external set value;

[0037] The analog output circuit is used to convert the simulation results and the corresponding proportional PWM signal into a standard analog signal for the process control system;

[0038] The communication interface circuit provides a communication interface for connecting with the host computer;

[0039] The control circuit and the human-computer interaction part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com