Microgrid operation control device

An operation control and micro-grid technology, applied in the cooling/ventilation of substation/switchgear, substation/switch layout details, electrical components, etc. To achieve the effect of ensuring uniform blowing and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

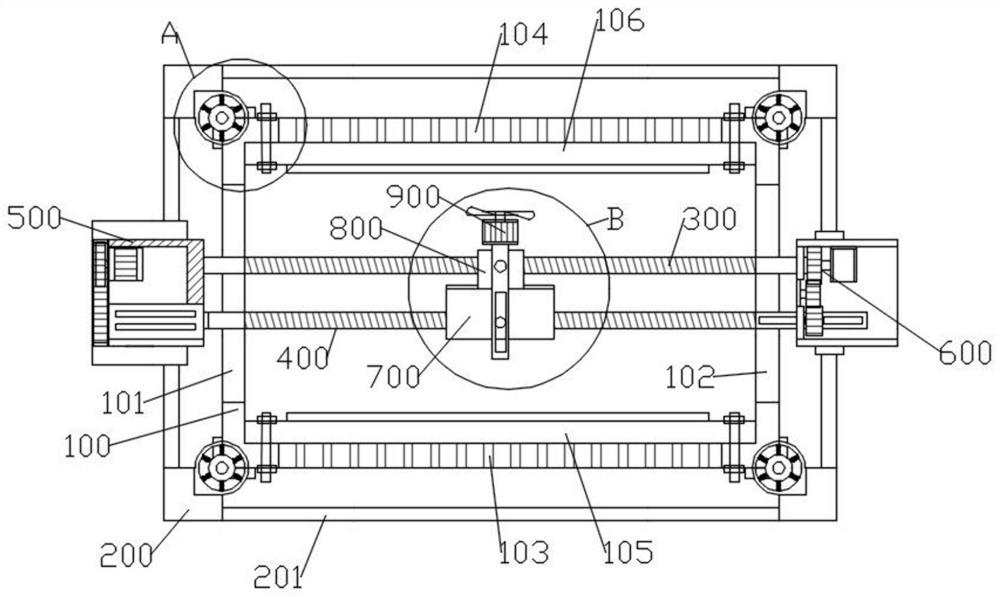

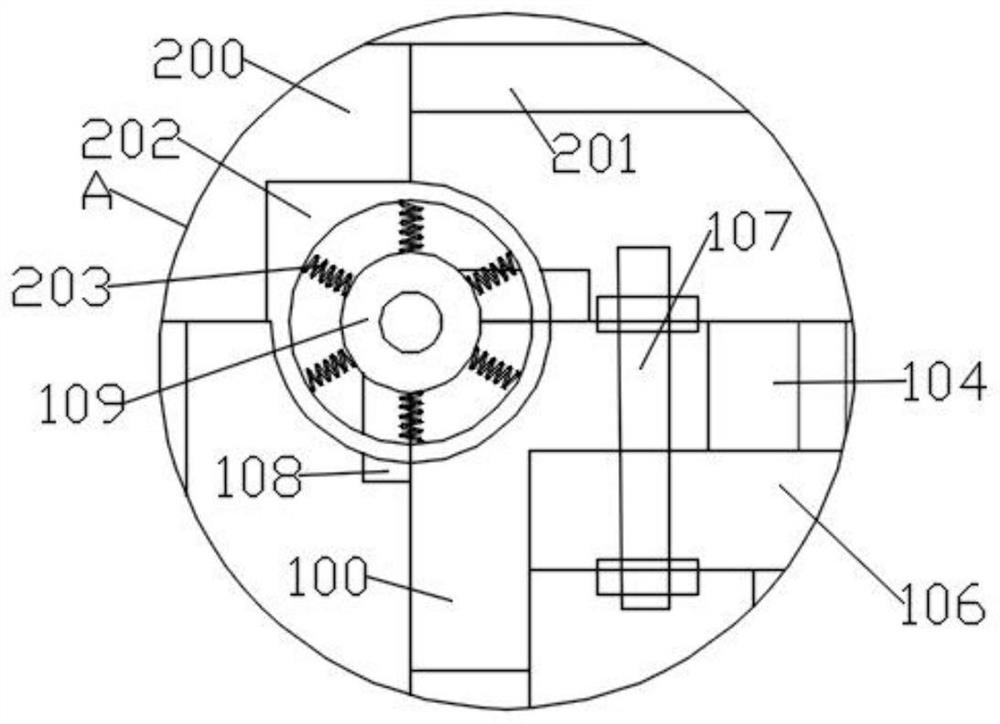

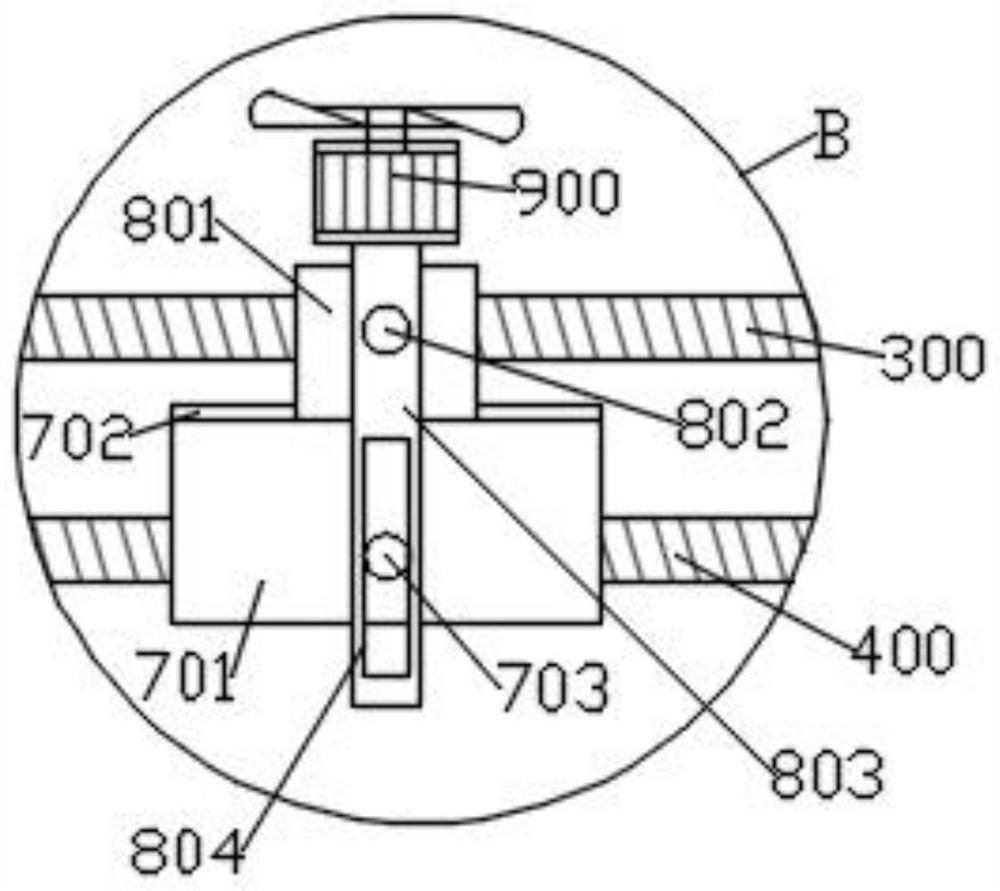

[0039] like Figure 1-2 As shown, in an embodiment provided by the present invention, a microgrid operation control device, the control device includes:

[0040] An adjustment member 500 arranged on one side of the protective shell 200;

[0041] The driver 600 arranged on the other side of the protective shell 200;

[0042] The heat dissipation mechanism located in the box body 100, the position of the heat dissipation mechanism in the box body 100 is adjusted through the screw group, and the screw group is driven by the driving member 600; the screw group includes a structure The same first screw mandrel 300 and second screw mandrel 400, the relative position between the first screw mandrel 300 and the second screw mandrel 400 is adjusted through the adjustment member 500; the heat dissipation mechanism includes a blower 900 , the blower 900 is rotatably installed on the positioning member 800, and the positioning member 800 is installed on the first screw rod 300; Adjustm...

Embodiment 2

[0046] like Figure 1-2 As shown, in an embodiment provided by the present invention, a microgrid operation control device, the control device includes:

[0047] An adjustment member 500 arranged on one side of the protective shell 200;

[0048] The driver 600 arranged on the other side of the protective shell 200;

[0049] The heat dissipation mechanism located in the box body 100, the position of the heat dissipation mechanism in the box body 100 is adjusted through the screw group, and the screw group is driven by the driving member 600; the screw group includes a structure The same first screw mandrel 300 and second screw mandrel 400, the relative position between the first screw mandrel 300 and the second screw mandrel 400 is adjusted through the adjustment member 500; the heat dissipation mechanism includes a blower 900 , the blower 900 is rotatably installed on the positioning member 800, and the positioning member 800 is installed on the first screw rod 300; Adjustm...

Embodiment 3

[0063] like Figure 1-2 As shown, in an embodiment provided by the present invention, a microgrid operation control device, the control device includes:

[0064] An adjustment member 500 arranged on one side of the protective shell 200;

[0065] The driver 600 arranged on the other side of the protective shell 200;

[0066]The heat dissipation mechanism located in the box body 100, the position of the heat dissipation mechanism in the box body 100 is adjusted through the screw group, and the screw group is driven by the driving member 600; the screw group includes a structure The same first screw mandrel 300 and second screw mandrel 400, the relative position between the first screw mandrel 300 and the second screw mandrel 400 is adjusted through the adjustment member 500; the heat dissipation mechanism includes a blower 900 , the blower 900 is rotatably installed on the positioning member 800, and the positioning member 800 is installed on the first screw rod 300; Adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com