Waste cable recovery sheath removal device

A sheathing and cable technology, which is applied in the direction of cable installation device, cable installation, dismantling/armouring cable equipment, etc., can solve the problems that the work efficiency of cable peeling cannot be improved, multiple cutting devices are installed, and labor costs are increased. , to achieve the effect of reducing the steps of manual size adjustment, improving practicability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

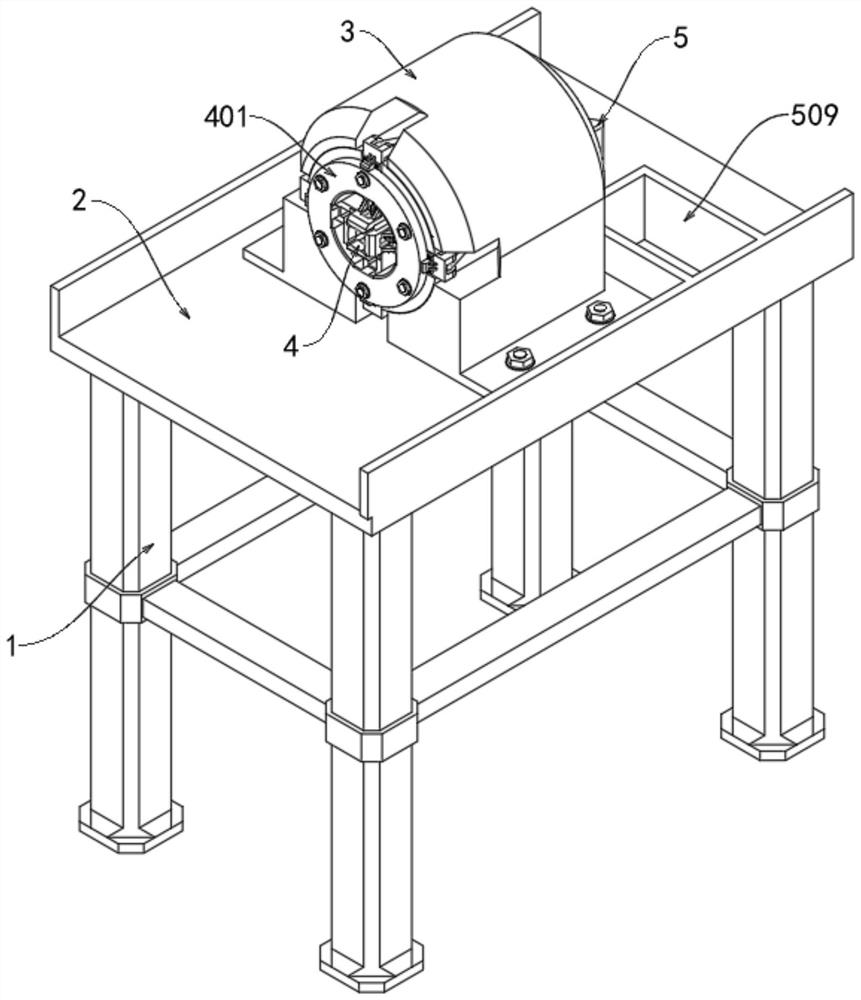

[0032] Please refer to Figure 1 to Figure 3 As shown, a waste cable recovery sheath removal device includes a support frame 1, the inner upper end of the support frame 1 is fixedly connected with a workbench 2, the upper surface of the workbench 2 is fixedly connected with a fixed base 3, and the inside of the fixed base 3 is fixed The adapter mechanism 4 is connected, and the inside of the adapter mechanism 4 is provided with a collection mechanism 5 .

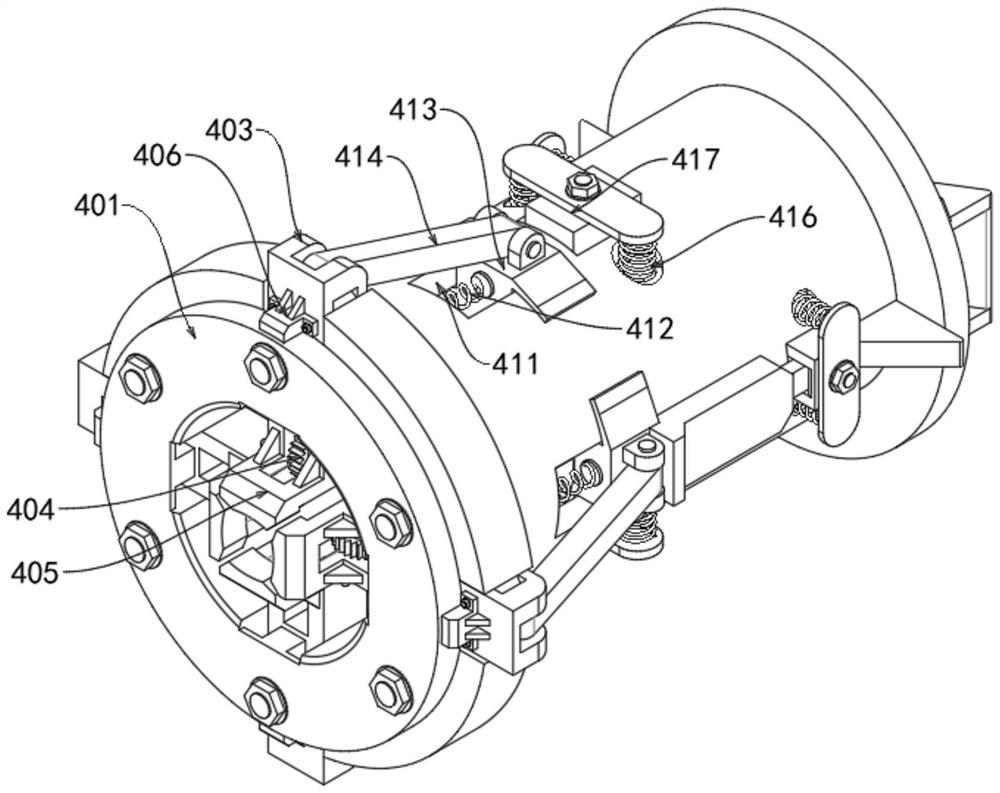

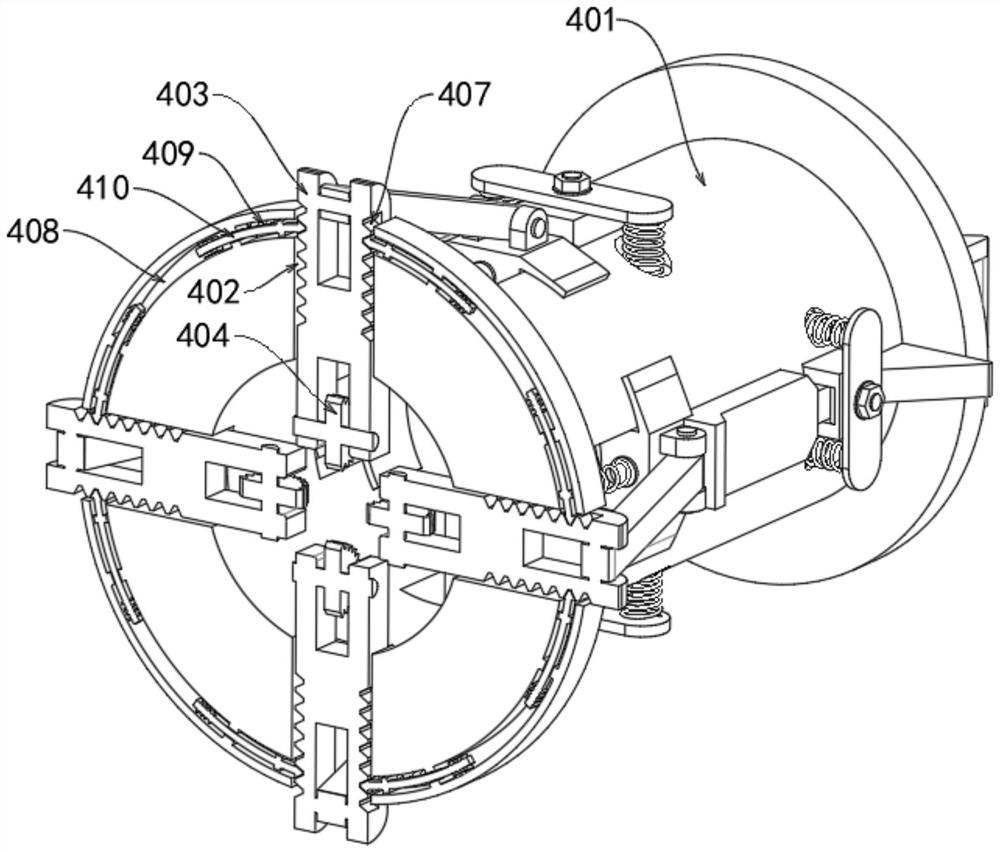

[0033] The adapter mechanism 4 includes a working base 401, a first movable port 402, an adapter block 403, a rolling tooth 404, a scraper 405 and a limit block 406. The inside of the fixed base 3 is fixedly connected with the working base 401, and the inside of the working base 401 There is a first movable port 402, and the inside of the first movable port 402 is movably connected with an adapter block 403, and the inner side of the adapter block 403 and close to the inner part of the working base 401 is rotatably connected...

Embodiment 2

[0038] Please refer to figure 2 and Figure 4 As shown, the adapter mechanism 4 also includes a chute 411, a second spring 412, a slider 413, a connecting rod 414, a second movable port 415, a third spring 416, a motor 417 and a peeling wheel 418, and the outer wall of the working base 401 A chute 411 is penetrated, the inner wall of the chute 411 is fixedly connected to one end of the second spring 412, the other end of the second spring 412 is fixedly connected to the inside of the chute 411 with a slider 413, and the inner side of the slider 413 is provided with The incline inclined at 45 degrees plays a role in pushing the motor 417 to move inward. The slider 413 moves inside the chute 411. The outer side of the slider 413 is rotationally connected with one end of the connecting rod 414, and the other end of the connecting rod 414 Rotately connected with the outside of the adapter block 403, the outer wall of the working base 401 is penetrated with a second movable openi...

Embodiment 3

[0041] Please refer to figure 1 , Figure 5 and Figure 6 As shown, the collection mechanism 5 includes a third movable port 501, a connecting plate 502, a push block 503, a fourth spring 504, a movable block 505, a push port 506, a collection scraper 507, a collection guide plate 508 and a collection port 509, and the working base The outer wall of 401 is provided with a third movable opening 501, the outer side of the slider 413 is fixedly connected with a connecting plate 502, and the outer side of the connecting plate 502 is fixedly connected with a push block 503, and the outer side of the push block 503 is provided with a slope inclined at 45 degrees. The movable block 505 can be driven to move outward under the action of the inclined surface of the push block 503, the outer wall of the working base 401 is fixedly connected with the fourth spring 504, and the outer side of the fourth spring 504 and the inside close to the third movable port 501 are fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com