A touch pad alignment device

An alignment device and touchpad technology, applied in the direction of assembling printed circuits, printed circuits, electrical components, etc. with electrical components, which can solve the problems of easily damaged touchpads and low adaptability, achieve rapid positioning, and reduce contact area. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

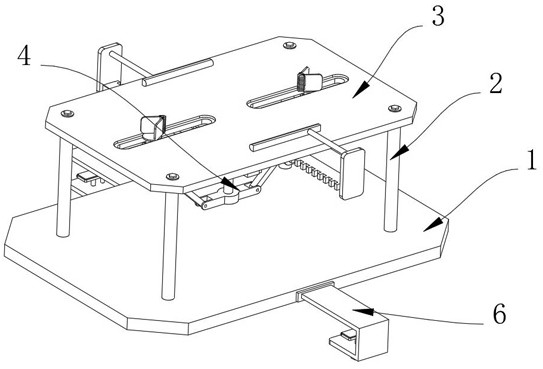

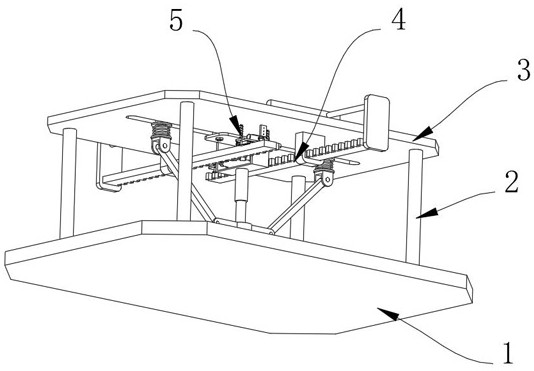

[0043] Example 1, as Figure 1-8 As shown, the present invention provides a touchpad fitting and alignment device, which includes a backing plate 1 and a positioning structure 4. The four corners of the upper surface of the backing plate 1 are fixedly connected with support rods 2, and the upper ends of the four support rods 2 are fixedly connected. There is a positioning plate 3 , a positioning structure 4 is arranged on the surface of the positioning plate 3 , a lubricating structure 5 is arranged at the position of the positioning plate 3 corresponding to the rack 411 , and a limiting structure 6 is arranged on both sides of the backing plate 1 .

[0044] The specific settings and functions of the positioning structure 4 , the lubricating structure 5 and the limiting structure 6 will be described in detail below.

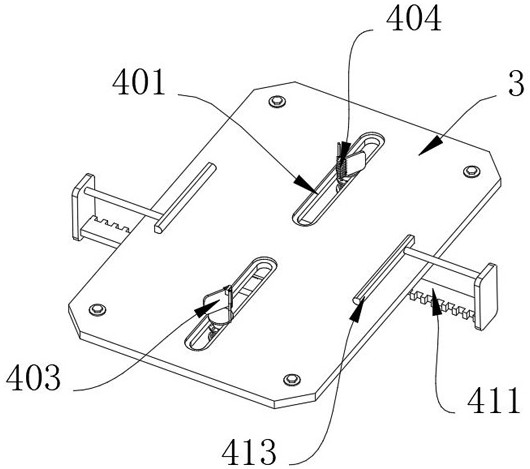

[0045] like Figure 4 and Figure 5 As shown, the positioning structure 4 includes two sliding holes 401, both of which are opened on the surface of the positi...

Embodiment 2

[0049] Embodiment 2, on the basis of embodiment 1, as figure 1 and Figure 8 As shown, the limiting structure 6 includes a mounting block 61, the mounting block 61 is welded on the surface of the backing plate 1, the side of the mounting block 61 away from the backing plate 1 is fixedly connected to the limiting frame 62, and the short arm end of the limiting frame 62 is threadedly inserted There is a screw 63, the upper end of the screw 63 is rotatably connected with a pressure plate 64, and the upper surface of the pressure plate 64 is fixedly connected with a silicone pad 65, so as to achieve the effect that the pad 1 can be quickly installed on the touch panel processing equipment by means of the screw 63 and the pressure plate 64. A sliding rod 66 is fixedly connected to the side of the pressing plate 64 close to the screw 63 , and the lower end of the sliding rod 66 slides through the limiting frame 62 , so as to limit the moving position of the pressing plate 64 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com