Feeding unit for feeding sealed semi-finished product packs containing pourable products into folding unit

A technology of semi-finished, sealed packs, applied in the field of feeding units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

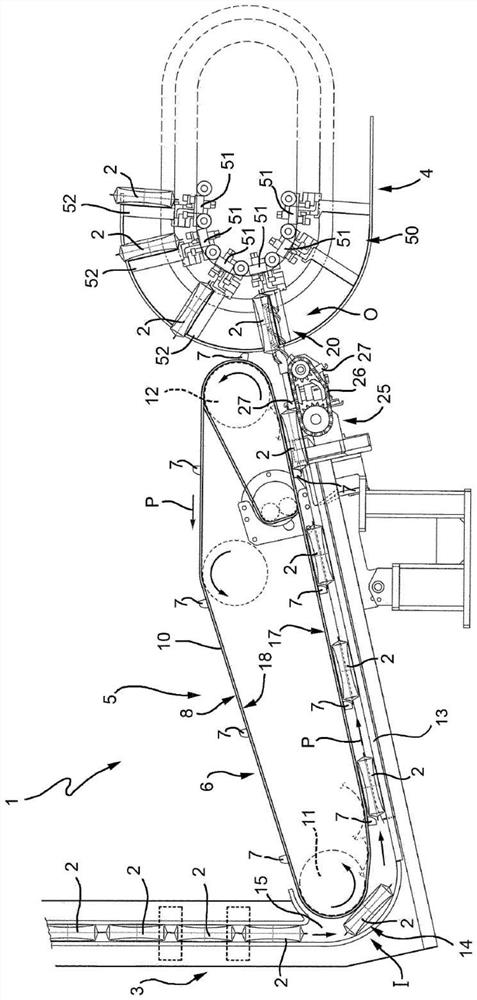

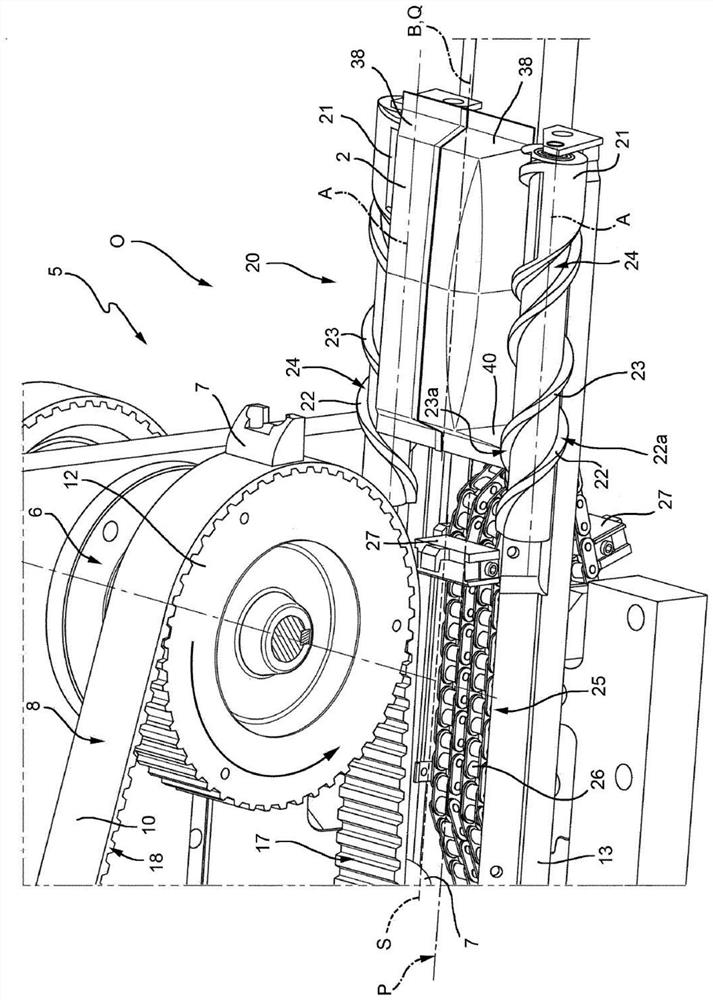

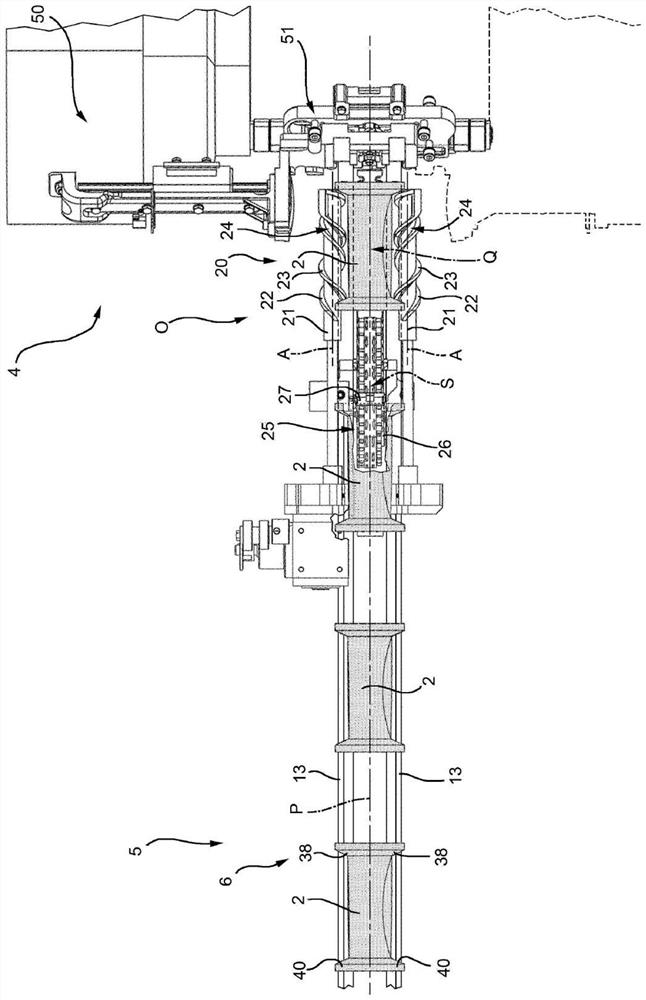

[0028] reference Figure 1 , marker 1 generally indicates a packaging component, which is configured to form, seal and fold a plurality of semi-finished packages containing a dumpable product (preferably dumpable food) starting from the packaging material tube (not shown) 2.

[0029] The packaging material has a multi-layer structure (not shown) and comprises a layer of fiber material (e.g., paper), two sides are covered with a heat-sealed plastic material (e.g., polyethylene) layer.

[0030] In the case of a sterile package 2 for long-term storage of the product (e.g., UHT milk), the packaging material further comprises a gas and light-blocking material layer, such as aluminum foil or vinyl alcohol (EVOH) film, which is stacked on a layer of heat-sealed plastic material, and then covered with another layer of heat-sealed plastic material, which forms the inner surface of the package 2 that finally contacts the dumpable product.

[0031]The tube is formed in a known manner by lon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap