Plastic optical fibre connector and formation of optical fibre and in shape of reverse-taper lens

A plastic optical fiber and connector technology, applied in the coupling of optical waveguides, etc., can solve the problems of complex operation, complex connector structure, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiment of the present invention is given below.

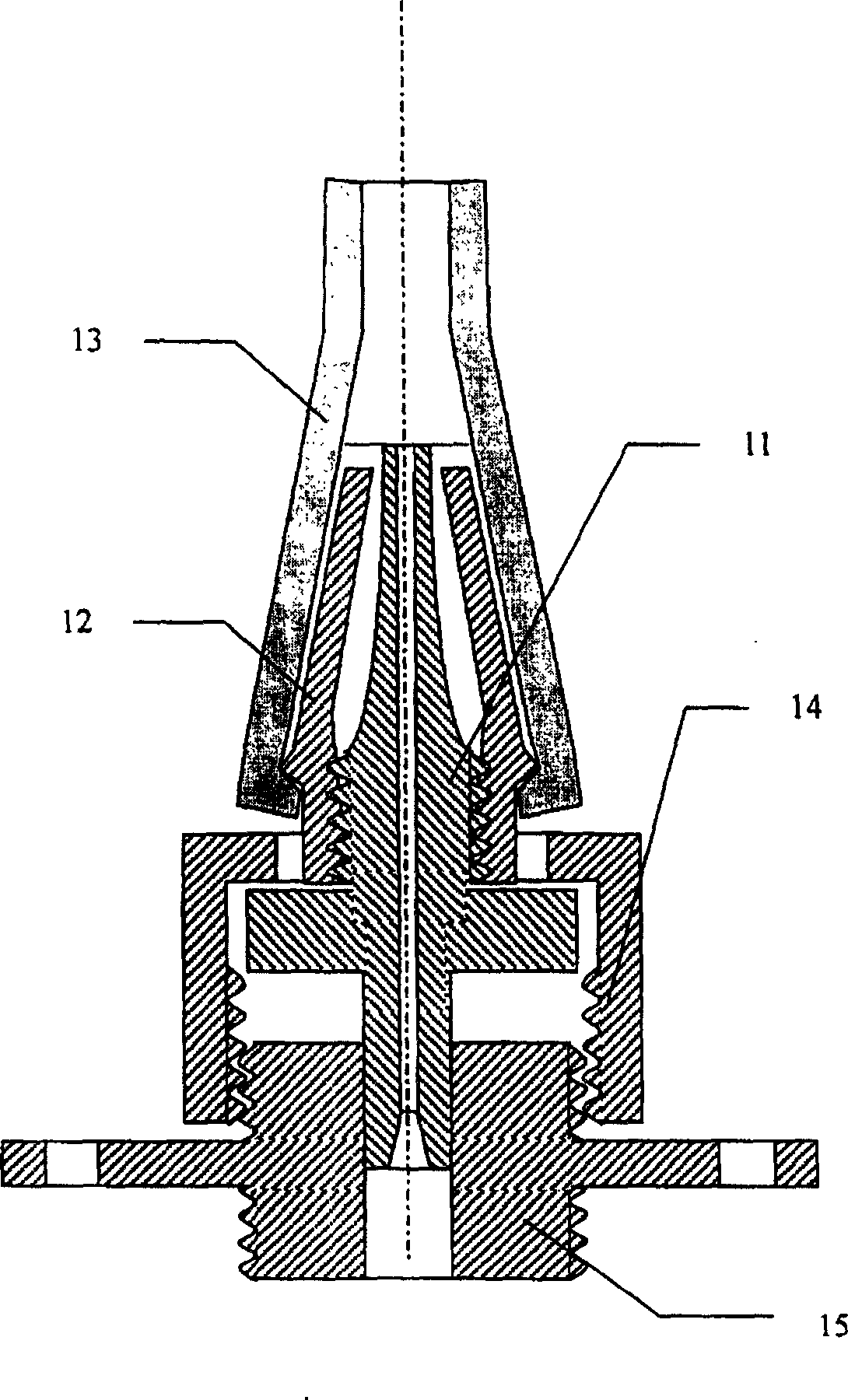

[0013] The plastic optical fiber connector involved in the present invention is as figure 1 As shown, it includes a stem [11], a tapered nut [12], a buffer sleeve [13], a connection cap [14] and an adapter [15]. There is an axial through hole in the stem [11], the diameter of which can be inserted into the plastic optical fiber. , the other end is tapered with grooves on it. The conical nut [12] is hollow, the upper part has a conical inner surface, and the lower part is a cylindrical internal thread, which is sleeved on the outside of the stem [11]. [11] The grooves on the outer tapered surface can firmly fasten the optical fiber and the sheath on the outer tapered surface of the core post [11]. The adapter [15] is a transition piece with a cylindrical external thread and a flange, and its external thread is docked with the connecting cap [14]. The flange of the adapter [15] is used to fix on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com