Stop seat for cone crusher

A technology of cone crusher and retaining seat, which is applied in grain processing, non-rotational vibration suppression, etc., can solve problems such as hidden dangers in the follow-up operation of the cone crusher, and achieve the effects of reducing maintenance costs, prolonging service life, and reducing horizontal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

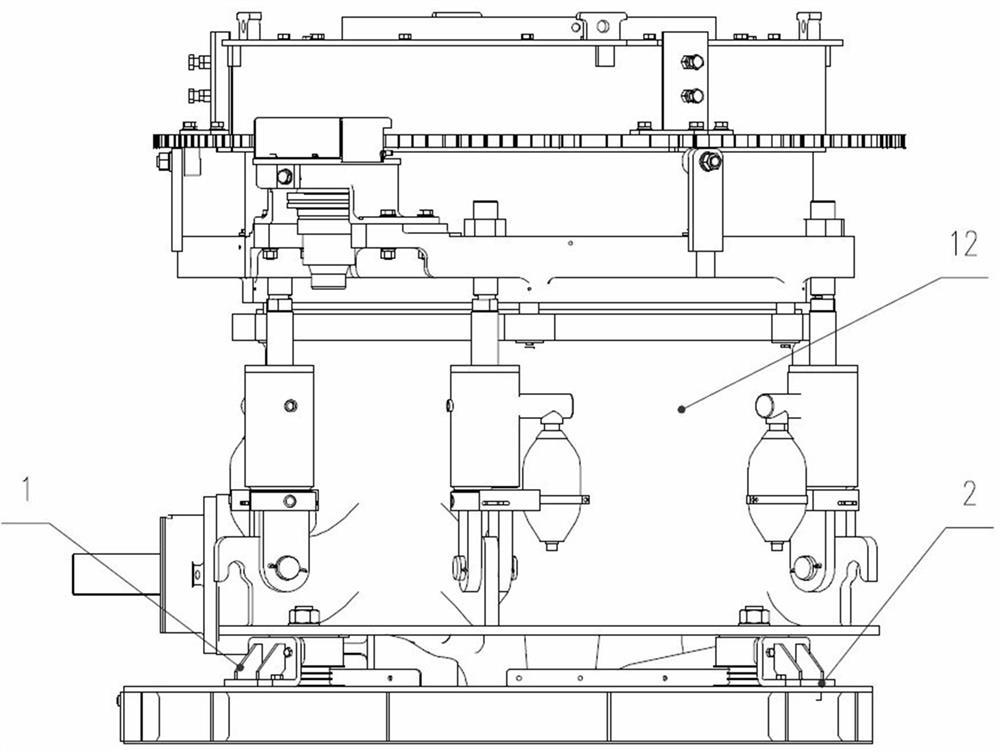

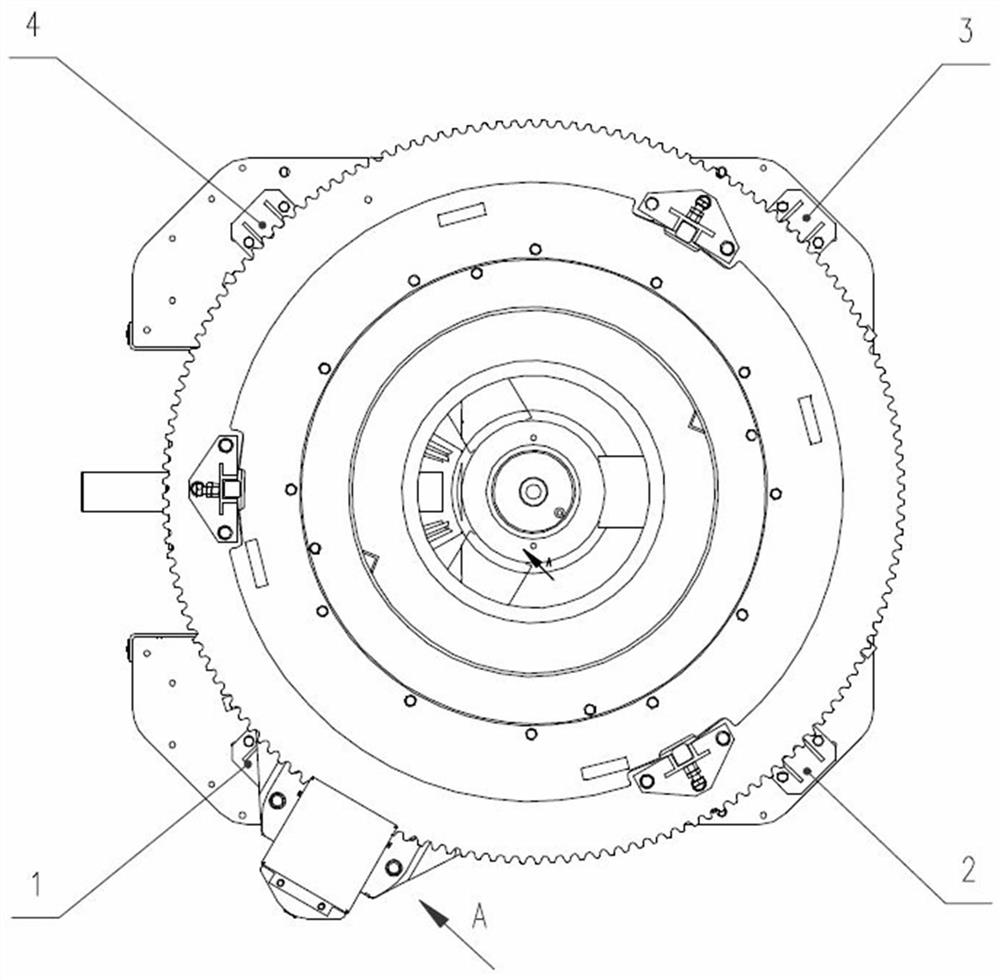

[0015] Such as Figure 1-3 As shown, the fixing devices of the cone crusher 12 of the present invention are divided into four groups, which are respectively: fixing device one 1, fixing device two 2, fixing device three 3, and fixing device four 4, which are evenly distributed in the cone crusher 12 along the circumferential direction. Around, for fixing the cone crusher 12.

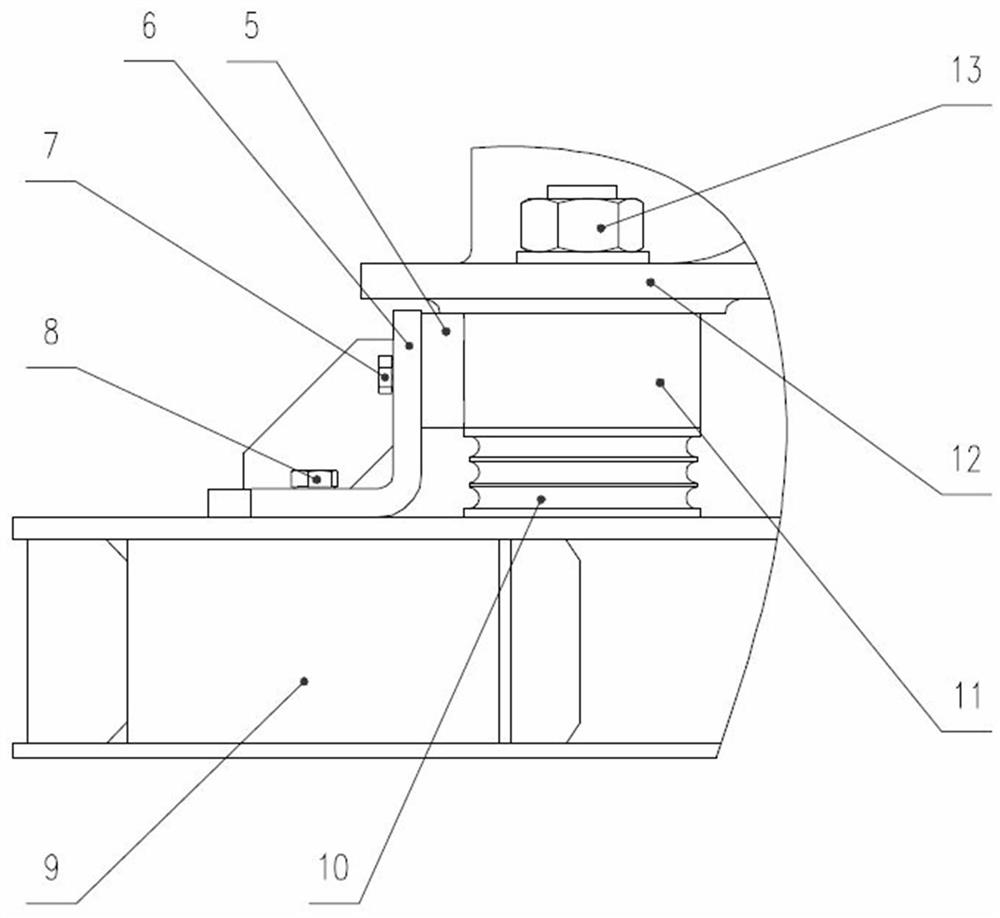

[0016] The fixing device of the cone crusher 12 includes a large nut 13 for fixing the cone crusher, a stopper 11, a vertical damping unit 10, a horizontal damping pad 5, a horizontal damping pad screw 7, a retaining seat 6, and a retaining seat screw 8 composition. The vertical shock absorbing unit 10 is fixed on the base 9, the vertical shock absorbing unit 10 has its own bolts, and there is a hole in the middle of the block 11, and the vertical shock absorbing unit 10 has its own bolts passing through the holes in the block 11 and the cone crusher The hole on the fixed plate of 12 is fixed by big nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com