Kit for detecting tuberculosis bacteria

A technology of kits and germs, applied in the field of kits, can solve the problems of potential safety hazards, reagents falling to the ground, and excessive force to extract them, so as to avoid falling damage and conveniently take the tuberculosis reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

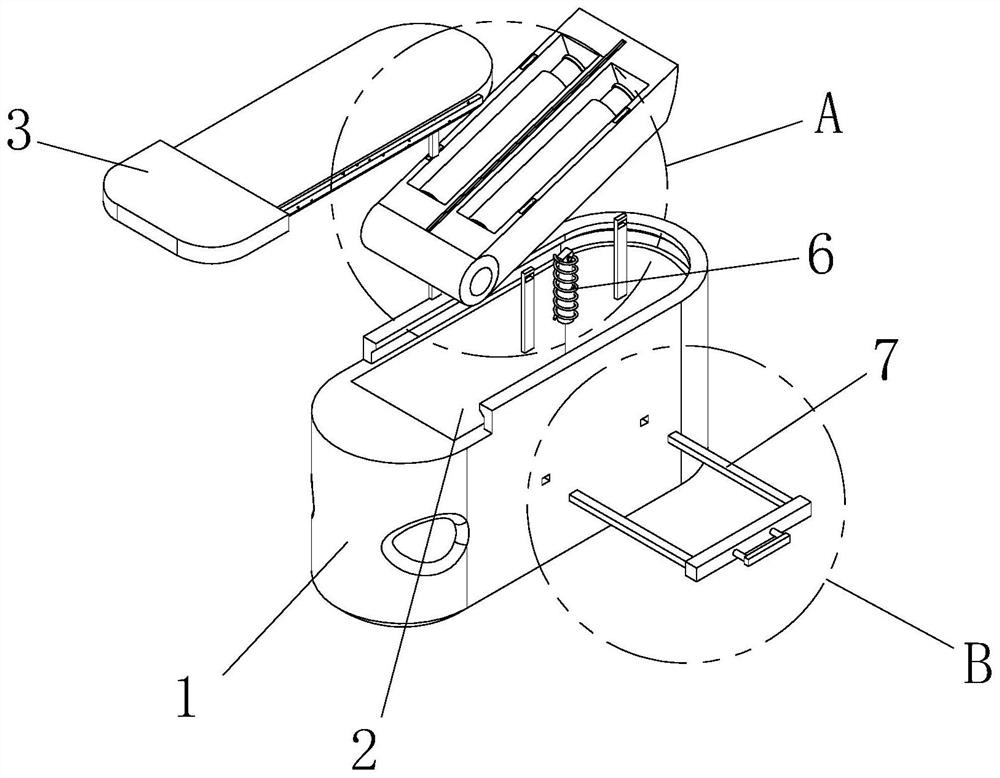

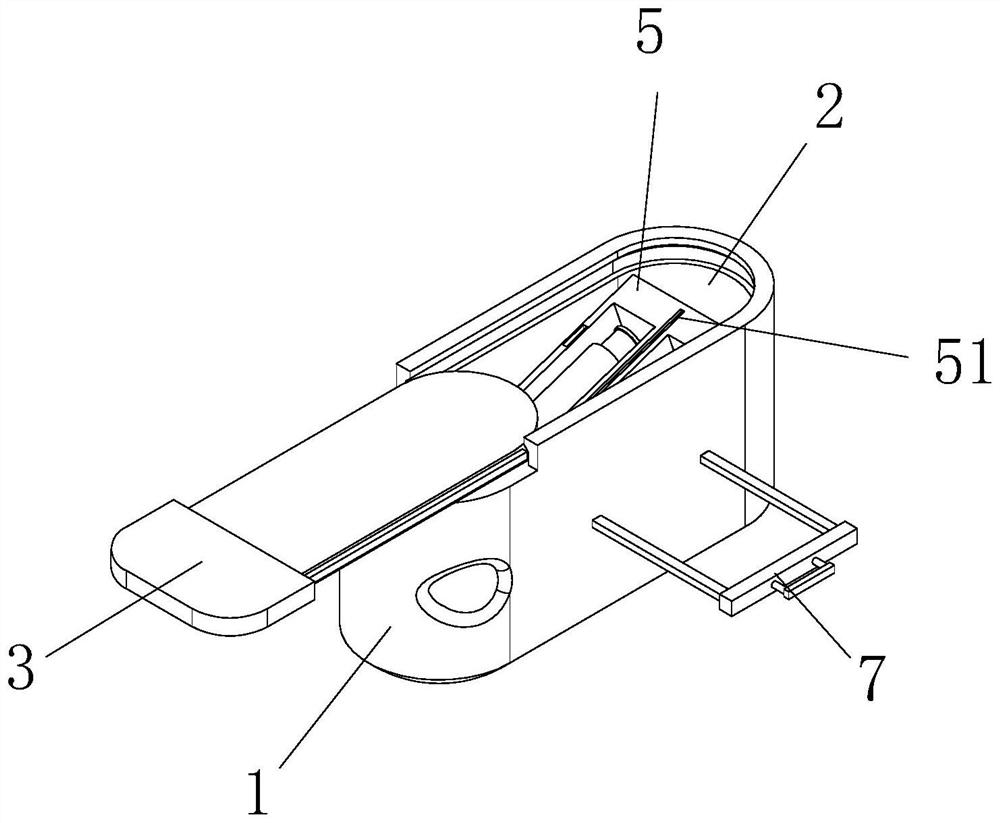

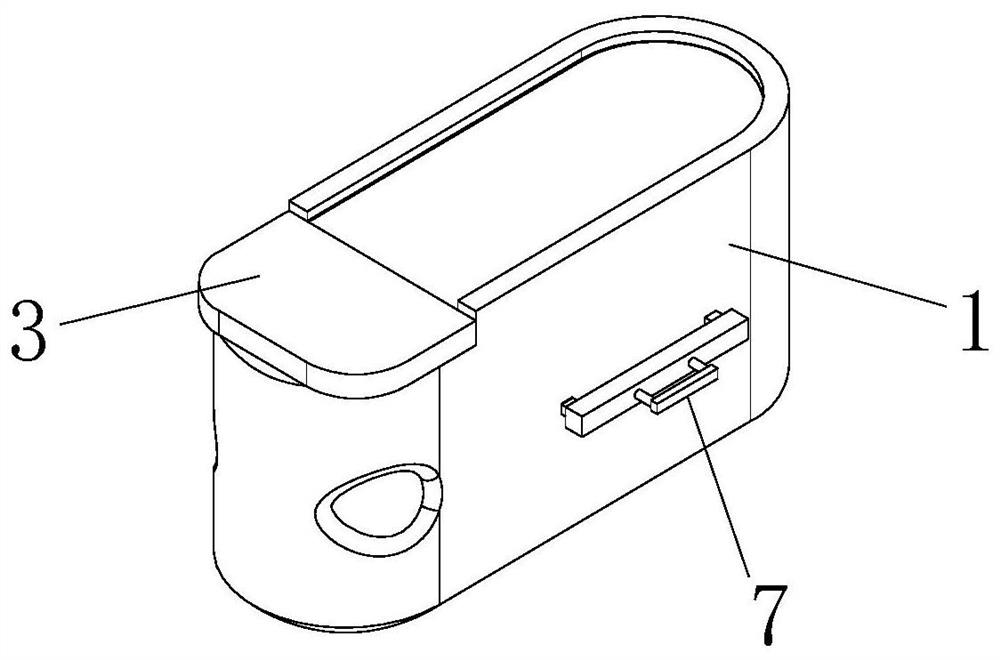

[0030] Such as figure 1 - Figure 9 As shown, a kit for testing tuberculosis bacteria includes a kit body 1, a kit cavity 2 is provided in the kit body 1, and the bottom of the kit cavity 2 is rotatably connected to a tuberculosis reagent 4. Place chamber 5. Concretely, place one end of cavity 5 (such as figure 1 The left end shown) is provided with a shaft hole, and the empty sleeve in the shaft hole is plugged with a rotating shaft, and the two ends of the rotating shaft are snapped and fixed on the inner walls of both sides of the reagent box cavity 2, so that the placement cavity 5 can be placed in the reagent box cavity 2 It rotates within a certain angle range around the rotating shaft.

[0031] The bottom of the placement cavity 5 is slidably connected with a take-out component 6 fixedly connected to the bottom surface of the reagent box cavity 2 . Such as Figure 4 to Figure 6 and Figure 8 As shown, the take-out assembly 6 includes a telescopic rod 61 fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com