Overhead valve type water decanter

A technology of decanter and top valve, applied in the direction of fixed filter elements, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as not suitable for sinking pools, burning pumps, easy to pump impurities, etc. Achieve the effect of easy cleaning of the pool bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

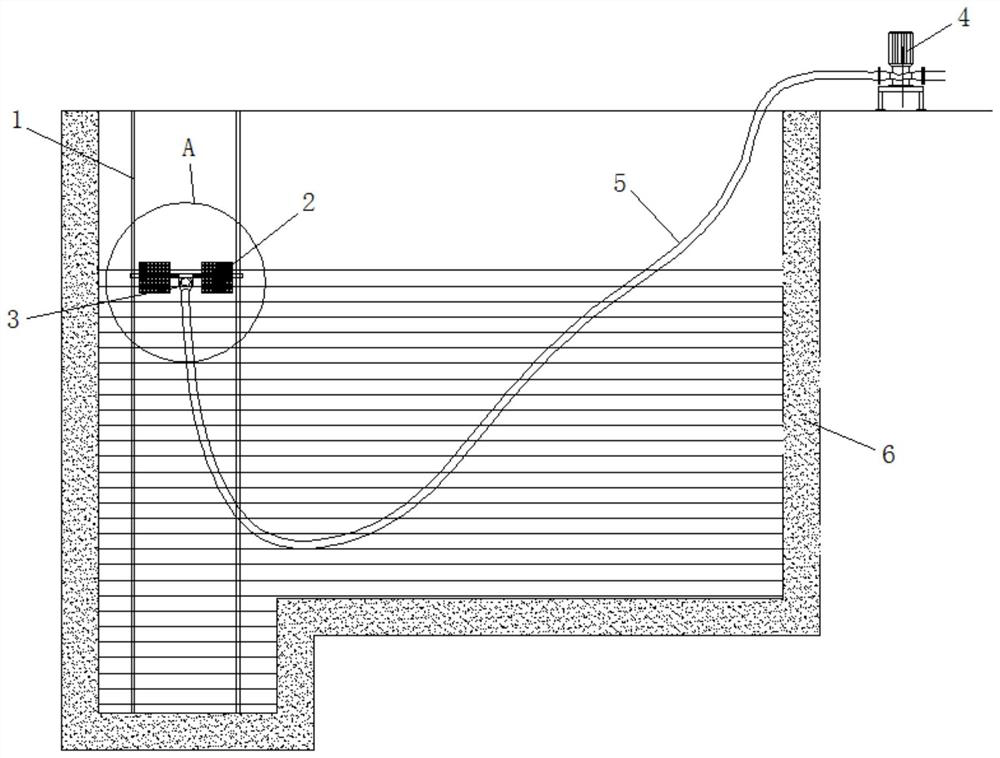

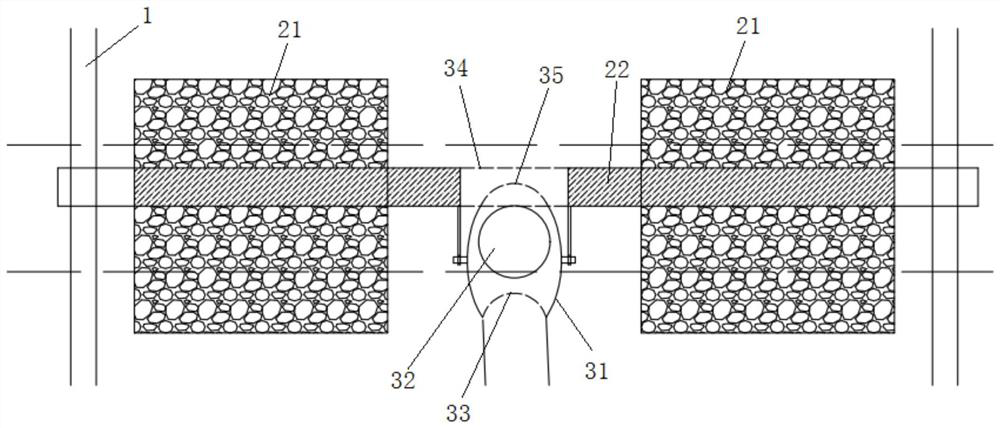

[0030] see figure 1 , figure 2 , a top valve decanter provided for the embodiment of the present invention, such as figure 1 , figure 2 As shown, the device may include:

[0031] A top valve assembly 3, the top valve assembly 3 is connected to the buoy assembly 2;

[0032] A slide rail assembly 1, the slide rail assembly 1 is arranged in the pool 6 and extends along the depth direction of the pool 6;

[0033] a buoy assembly 2, the buoy assembly 2 is mated with the slide rail assembly 1;

[0034] A lift pump assembly, the lift pump assembly comprising a connected lift pump main body 4 and a connecting hose 5;

[0035] Wherein, the water inlet of the top valve assembly 3 faces upwards and is located below the water surface; one end of the connecting hose 5 is connected to the lower end of the top valve assembly 3 .

[0036] The top valve decanter provided in the embodiment of the present application uses a buoy assembly to form a supporting device, lifts the top valve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com