Mixed iron car frame car machine control method for preventing data loss

A control method and data loss technology, applied in the direction of manufacturing tools, mechanical equipment, casting molten material containers, etc., can solve the problem of increased risk of overturning of mixed iron cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

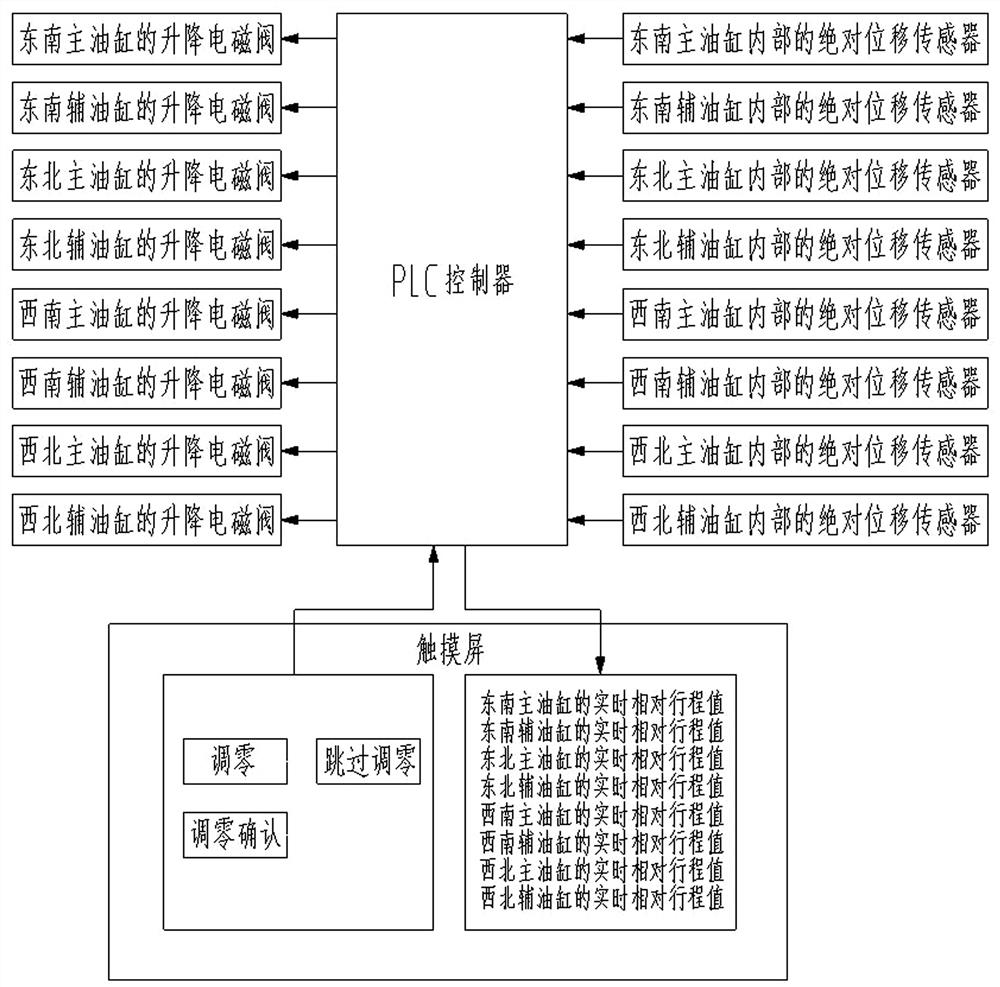

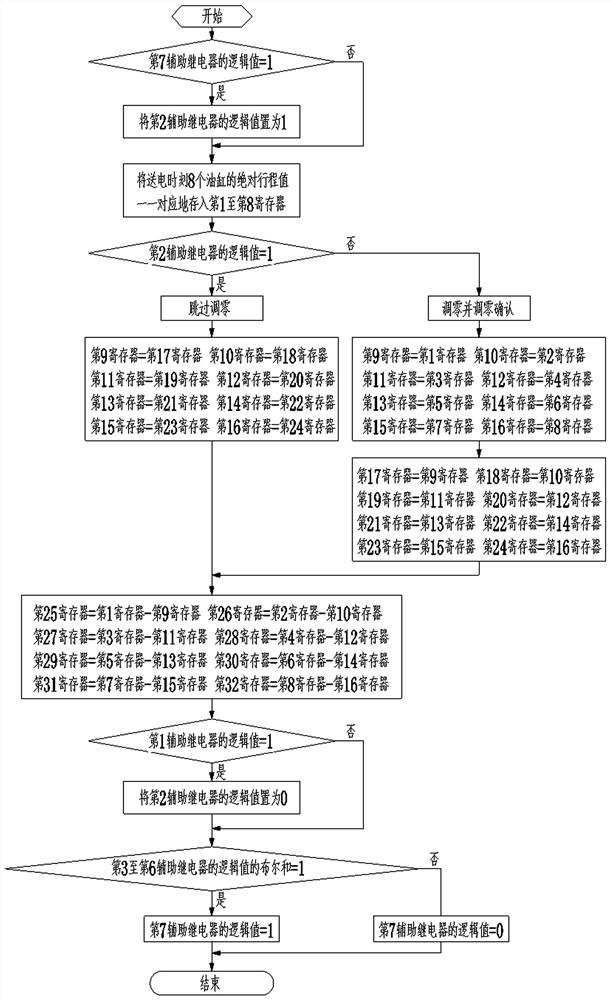

[0027] A control method for a mixed iron frame locomotive to prevent data loss, the method is realized by the following steps:

[0028] Step 1: Install 8 absolute displacement sensors one by one in the 8 oil cylinders of the mixed iron frame machine, and electrically connect the 8 absolute displacement sensors to the PLC controller of the mixed iron frame machine;

[0029] The 8 oil cylinders include: southeast main oil cylinder, southeast auxiliary oil cylinder, northeast main oil cylinder, northeast auxiliary oil cylinder, southwest main oil cylinder, southwest auxiliary oil cylinder, northwest main oil cylinder, northwest auxiliary oil cylinder;

[0030] Step 2: Define the 32 registers inside the PLC controller as the 1st to 32nd registers; the 1st to 16th registers, and the 25th to 32nd registers are power-down clear registers; the 17th to 24th registers are all power-down holding register;

[0031] Step 3: When the mixed iron frame machine is powered on, the 8 absolute d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap