Heavy-load clean goods elevator

A freight elevator and clean technology, which is applied in the field of freight elevators, can solve the problems that the purifier is easy to generate noise, affect the purification quality, and the cleanliness is low, so as to improve the sealing and structural strength, improve the circulation transmission effect, reduce power and electricity consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

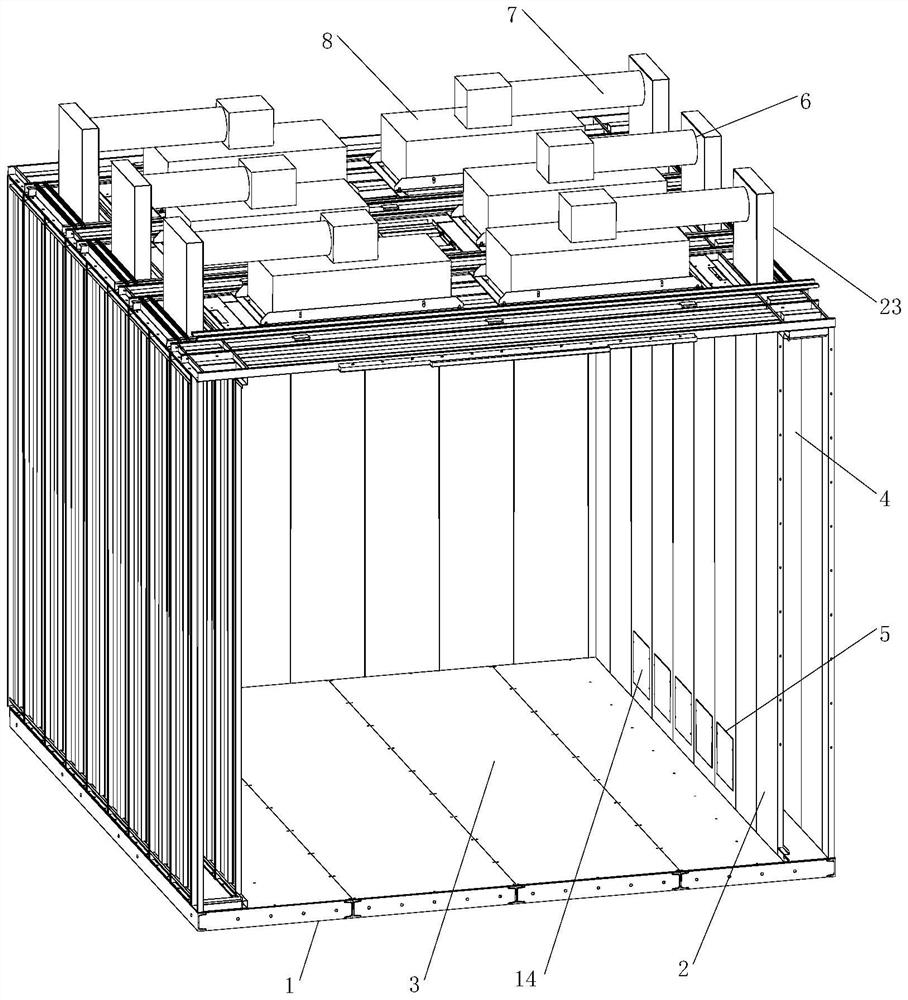

[0029] Example 1. A large-load clean freight elevator is constituted as Figure 1-4 As shown, including the elevator car 1, the size of the elevator car 1 is 4500mm*3600mm*3600mm, the elevator car 1 is provided with a partition 2, one side of the partition 2 forms a carrying part 3, and the other side of the partition 2 The air passage 4 is formed on the side, and the lower end of the air passage 4 is provided with an air inlet 5 connected to the carrying part 3. The top of the air passage 4 extends to the outside of the elevator car 1 and is provided with an air outlet 6. The outside of the air outlet 6 A purifier 8 located at the top of the elevator car 1 is connected through the air pipe 7 , and the air outlet end of the purifier 8 communicates with the carrying part 3 .

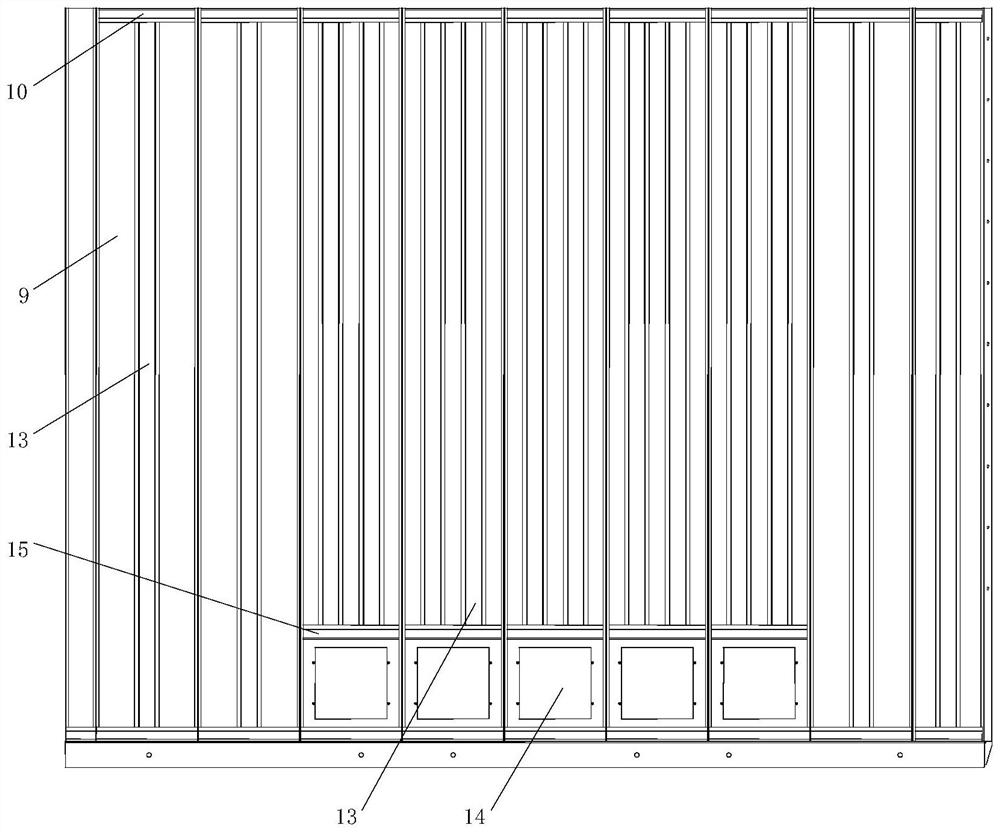

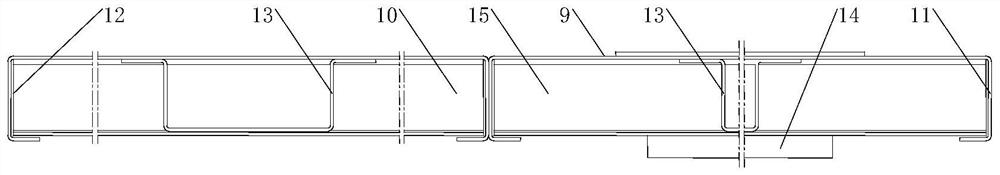

[0030] The structure of the side wall of the partition 2 and the elevator car 1 is the same, and both include a shutter 9, and a plurality of shutters 9 are connected to each other to form the partition ...

Embodiment 2

[0037] Example 2. A large-load clean freight elevator is constituted as Figure 1-3 and Figure 5 As shown, including the elevator car 1, the size of the elevator car 1 is 4500mm*3600mm*3600mm, the elevator car 1 is provided with a partition 2, one side of the partition 2 forms a carrying part 3, and the other side of the partition 2 The air passage 4 is formed on the side, and the lower end of the air passage 4 is provided with an air inlet 5 connected to the carrying part 3. The top of the air passage 4 extends to the outside of the elevator car 1 and is provided with an air outlet 6. The outside of the air outlet 6 A purifier 8 located at the top of the elevator car 1 is connected through the air pipe 7 , and the air outlet end of the purifier 8 communicates with the carrying part 3 .

[0038] The structure of the side wall of the partition 2 and the elevator car 1 is the same, and both include a shutter 9, and a plurality of shutters 9 are connected to each other to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com