LA-ICP-MS dynamic deformation beam spot test method and device

A LA-ICP-MS, dynamic deformation technology, applied in the preparation of test samples, measurement devices, instruments, etc., can solve the problems of not meeting the test technical requirements, unable to achieve laser beam spot deformation, etc., to save samples, reduce The effect of mixing impurities and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

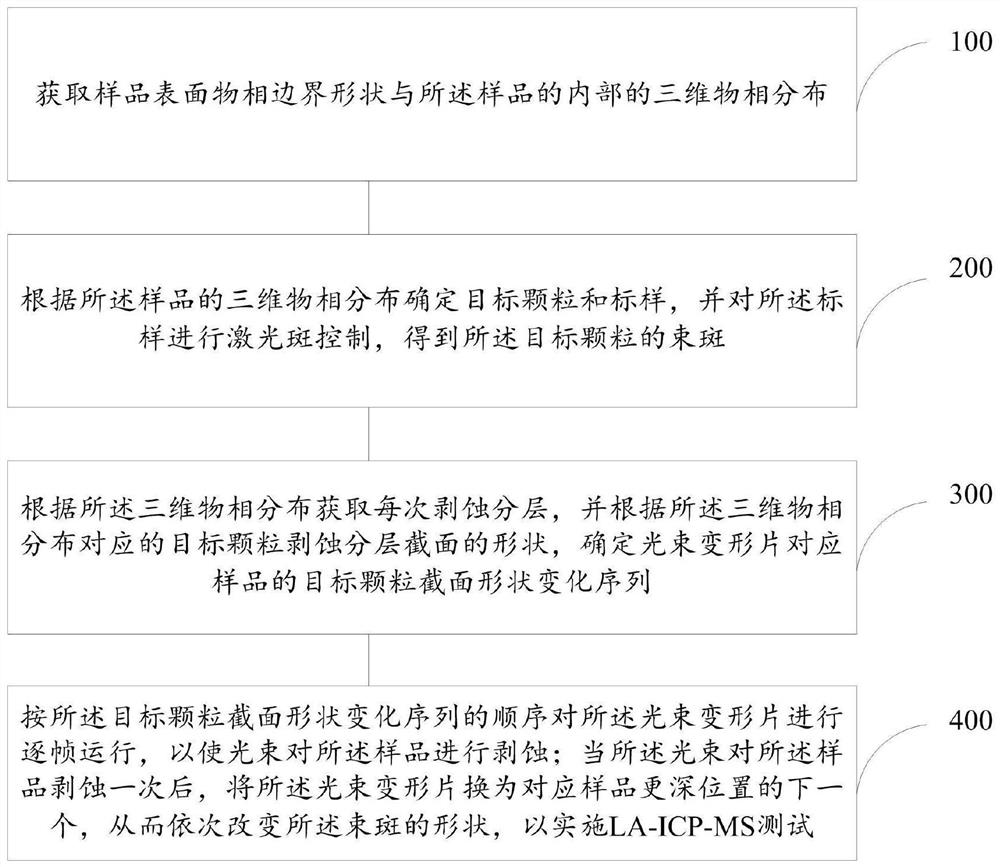

[0046] figure 1 The method flowchart in the embodiment 1 that the present invention provides, such as figure 1 As shown, the present invention provides a kind of testing method of LA-ICP-MS dynamic deformation beam spot, comprising:

[0047] Step 100: Obtain the phase boundary shape on the surface of the sample and the three-dimensional phase distribution inside the sample;

[0048] Step 200: Determine the target particle and the standard sample according to the three-dimensional phase distribution of the sample, and perform laser spot control on the standard sample to obtain the beam spot of the target particle;

[0049] Step 300 Obtain each ablation layer according to the three-dimensional phase distribution, and determine the shape change sequence of the cross-sectional shape of the target particle corresponding to the beam deformation sheet according to the shape of the ablation layer section of the target particle corresponding to the three-dimensional phase distribution...

Embodiment 2

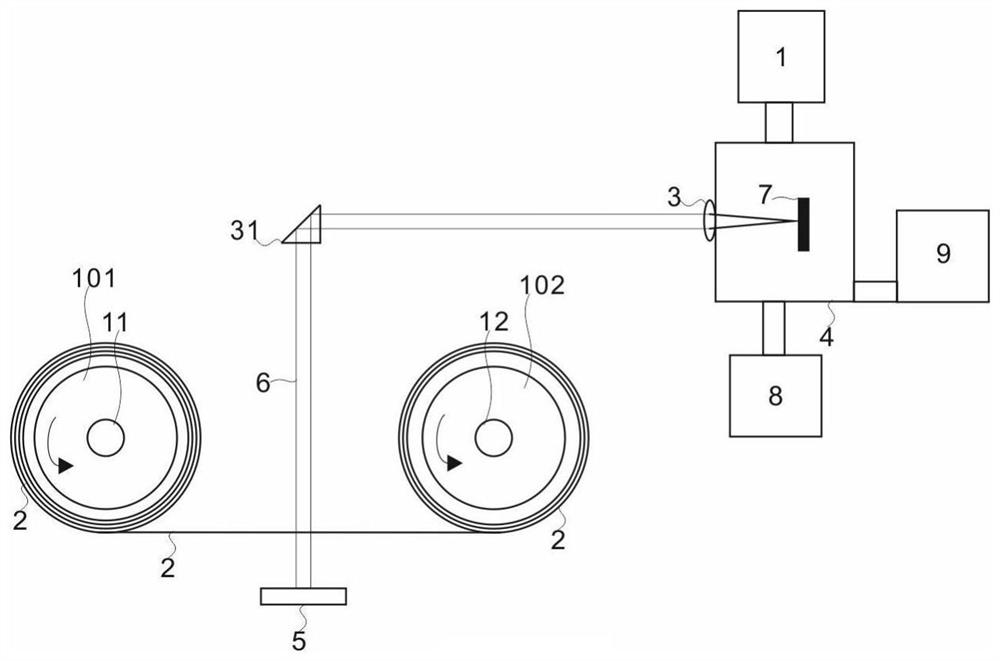

[0058] figure 2 The structural schematic diagram in the embodiment 2 that the present invention provides, as figure 2 As shown, the LA-ICP-MS equipment with dynamic deformation beam spot includes: mass spectrometer module 1, beam deformation plate 2, lens module 3, sample chamber 4, laser module 5, carrier gas module 8, vacuum module 9; beam deformation Sheet 2 is more than one film generated according to the three-dimensional layered structure of the sample 7; the pipeline of the sample chamber 4 is connected to the mass spectrometer module 1, the carrier gas module 8, and the vacuum module 9; the laser module 5 emits a light beam 6; when the sample chamber 4 When vacuumed by the vacuum module 9 and the sample 7 is detachably fixed, the beam 6 at least passes through the lens module 3 and the beam deformation plate 2 to form a beam spot 61 to ablate the sample 7, and the beam 6 can also be a parallel beam or a beam of non-ablative energy range A prism module 31 is added, a...

Embodiment 3

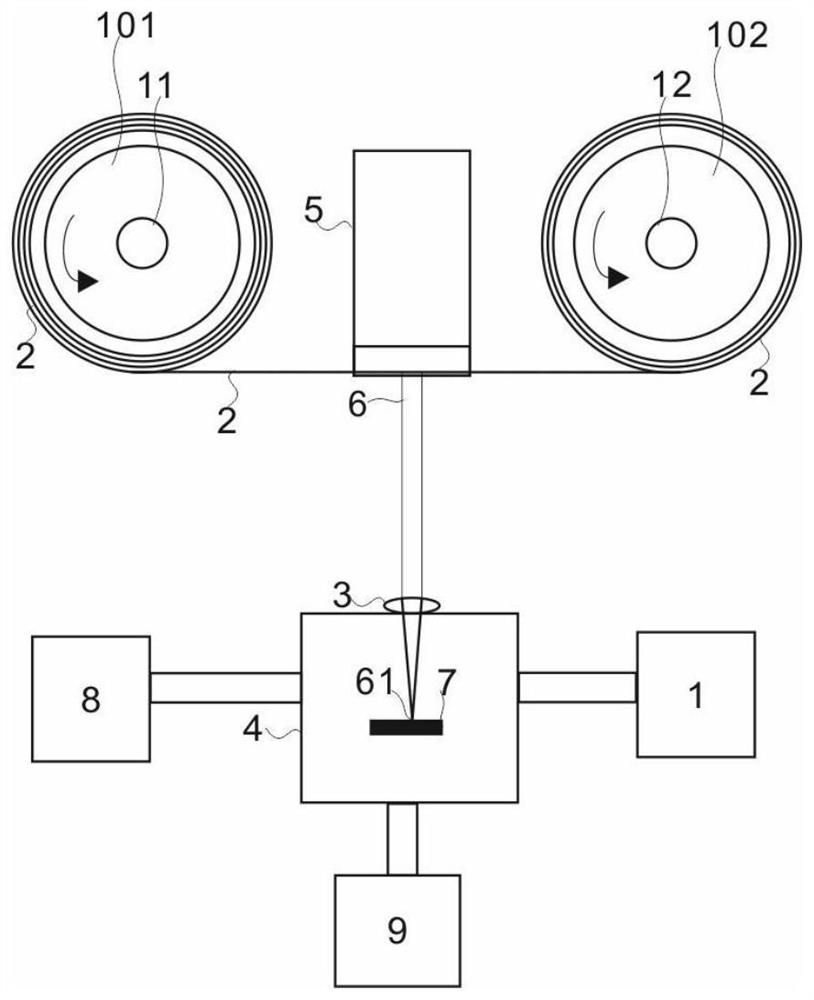

[0060] image 3 The structural representation in the embodiment 3 provided for the present invention, such as image 3 As shown, compared with the above, the beam deforming sheet 2 of Example 3 is a sheet-like excitation source arranged in a strip shape, which directly changes the shape of the excitation source, thereby changing the shape of the light source. The shape of the beam spot 61 can be constrained by changes in the shape of the light source at a distance greater than twice the focal length of the convex lens of the lens module by known techniques. At this time, the beam deforming sheet 2 passes through the laser module 5 in one direction. When the beam deforming sheet 2 passes through, the position of the beam 6 emitted by the laser module 5 is attached but not fixed to change the shape of the beam 6 . The first stepping motor 11 drives the first rotating wheel 101, and the beam deformation sheet 2 that has not passed the laser module 5 is wound and fixed by the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com