Electric balance test method for standard working condition of whole vehicle

A test method and electric balance technology, applied in the direction of measuring electricity, measuring devices, measuring electric variables, etc., can solve the problems that the test results are not suitable for the evaluation of Chinese automobile electric balance, and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

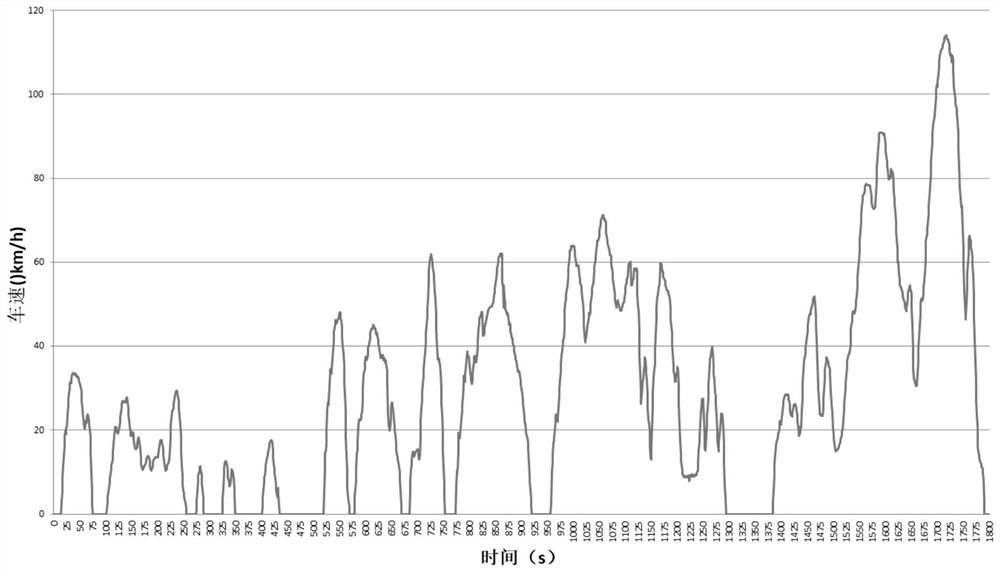

[0049] Embodiment 1. The electric balance test method of the vehicle standard working condition described in this embodiment is realized based on the CLTC-P working condition, and the method is:

[0050] Place the vehicle to be tested in the wheel hub environment chamber, the initial SOC of the vehicle battery is 70%, set the temperature of the wheel hub environment chamber as the test temperature, and when the temperature of the wheel hub environment chamber reaches the set test temperature, maintain 8 hour, and then start the following steps;

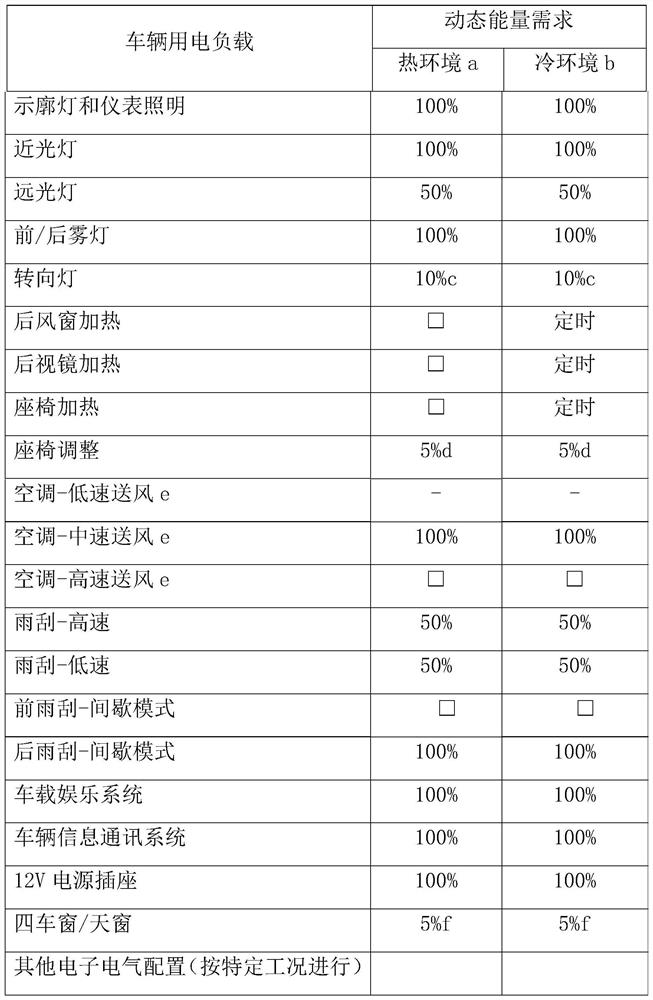

[0051] Start the engine, wait for the idle speed to be in the normal working state, turn on the corresponding vehicle electrical equipment in turn, and keep the vehicle electrical equipment open until the end of the following test;

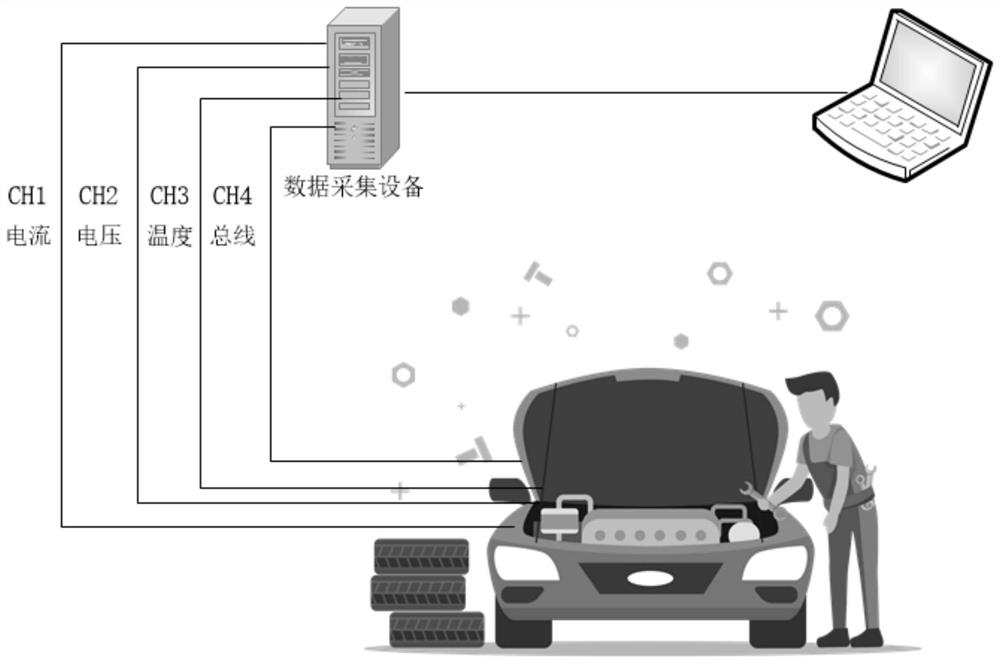

[0052] Turn the rotating hub equipment, drive the vehicle according to the CLTC-P working condition until the test is completed; in the process, monitor the charging and discharging current signal of the ...

Embodiment approach 2

[0060] Embodiment 2. This embodiment is a further limitation of the electric balance test method for the standard working condition of the vehicle described in the first embodiment. In this embodiment, the target value is the power demand of the vehicle under the standard working condition.

[0061] The electric power demand of the vehicle under standard operating conditions is set before the test, for example, it can be set to 70% of the capacity of the on-board storage battery of the vehicle to be tested.

Embodiment approach 3

[0062] Embodiment 3. This embodiment is a further limitation of the electric balance test method of a vehicle standard working condition described in Embodiment 1 or 2. In this embodiment, the test temperature includes low-temperature environment test temperature and high-temperature environment The two-parameter test temperature, the low-temperature environment test temperature simulates a cold environment, simulating the temperature on a snowy night in winter; the high-temperature environment test temperature simulates a hot environment, simulating the temperature on a summer rainy night.

[0063] In the actual test process, the hot environment and the cold environment are tested separately, and the test process of each environment is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com