Positive pole piece for lithium-sulfur battery and preparation method of positive pole piece

A technology of positive electrode and lithium-sulfur battery, applied in the field of positive electrode and its preparation, can solve the problems of reduced Coulomb efficiency, increase of negative charge transfer resistance, loss of positive electrode capacity, etc. The effect of optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

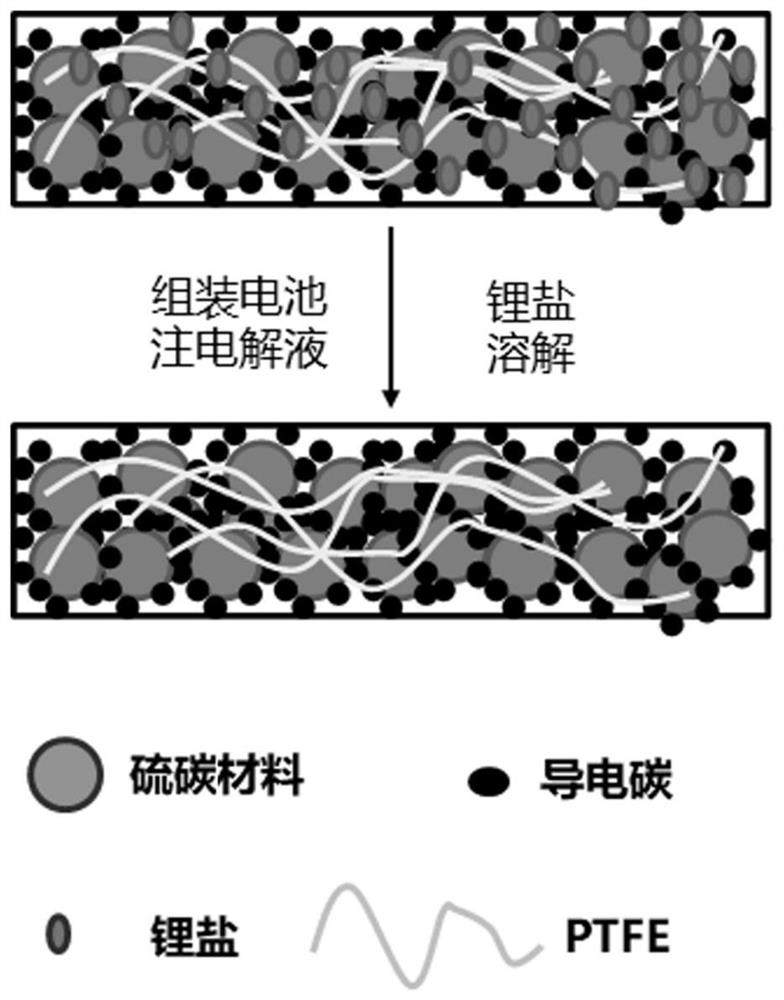

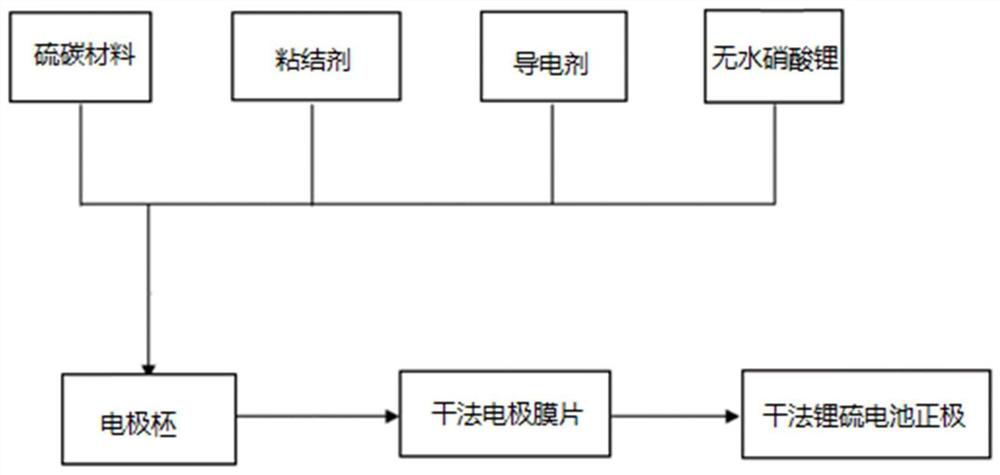

[0026] This embodiment provides a high-porosity dry-process lithium-sulfur battery positive electrode, the preparation method of which is as follows: figure 2 As shown, in a dry room with a relative humidity 3 ) anhydrous lithium nitrate with a total volume of 25%, then shear and grind, and obtain a whole piece of uniform electrode blank after fibrillation of PTFE particles; roll the electrode blank at 38°C to make a dry electrode membrane The dry electrode diaphragm provided by the present embodiment is cut, and its thickness and area are tested. According to the true density of each component material, the porosity of the dry electrode diaphragm is calculated to be 45.2%, and the lithium nitrate is dissolved in the electrolyte. The porosity of the porous dry electrode membrane is 58.9%. Paste the dry-process electrode diaphragm on the carbon-coated aluminum foil current collector with conductive adhesive to make LiNO 3 The positive electrode of the dry-process lithium-sulf...

Embodiment 2

[0028] This embodiment provides a high-porosity dry-process lithium-sulfur battery positive electrode, the preparation method of which is the same as that of Embodiment 1, the difference is as follows: in a dry room with a relative humidity 3 The positive electrode of the dry-process lithium-sulfur battery accounts for 22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com