High heat dissipation type printed circuit board and automobile heat dissipation system

A printed circuit board, high heat dissipation technology, applied in the direction of printed circuit, printed circuit, circuit heating device, etc., can solve the problems of unfavorable use, increase the occupied area of high-power devices, etc., achieve increased heat dissipation capacity, good heat dissipation performance, and avoid The effect of occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

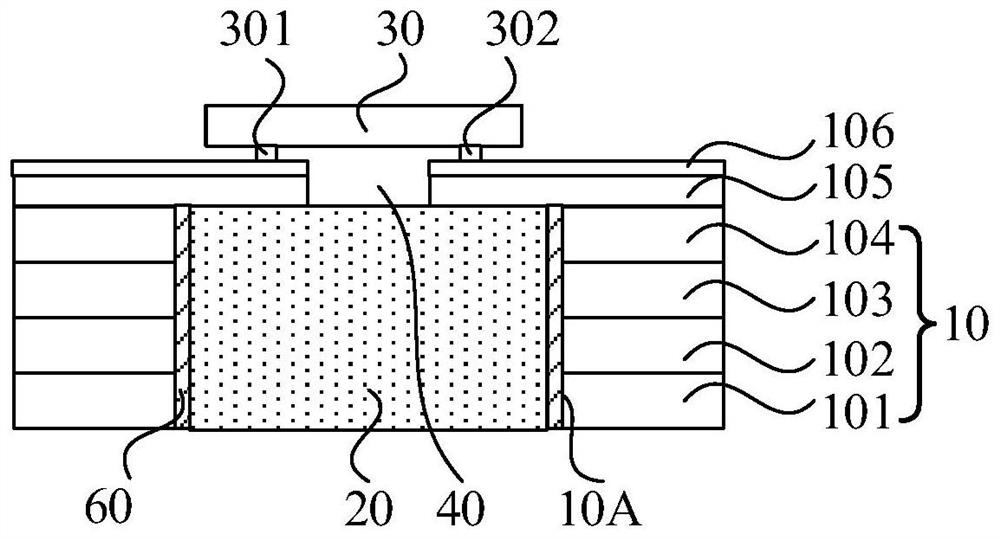

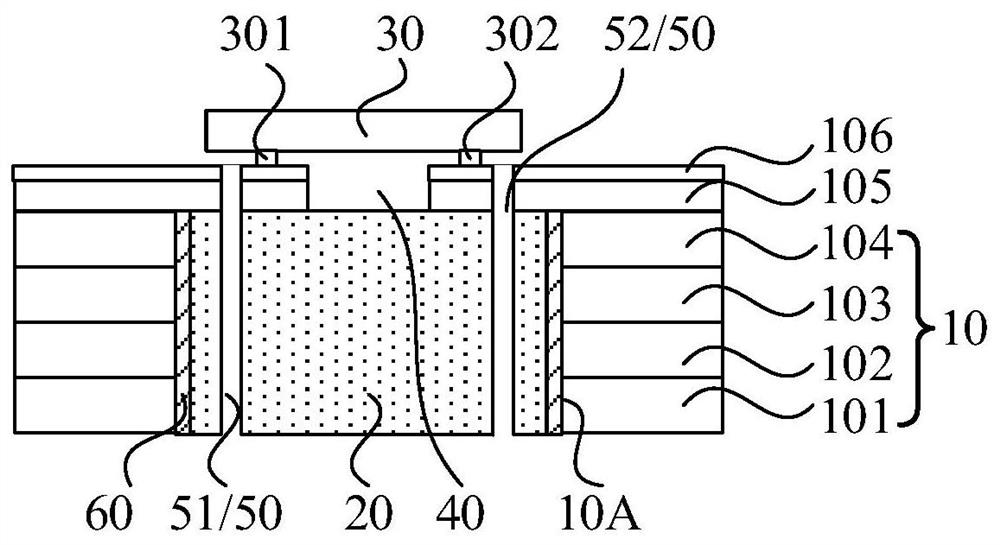

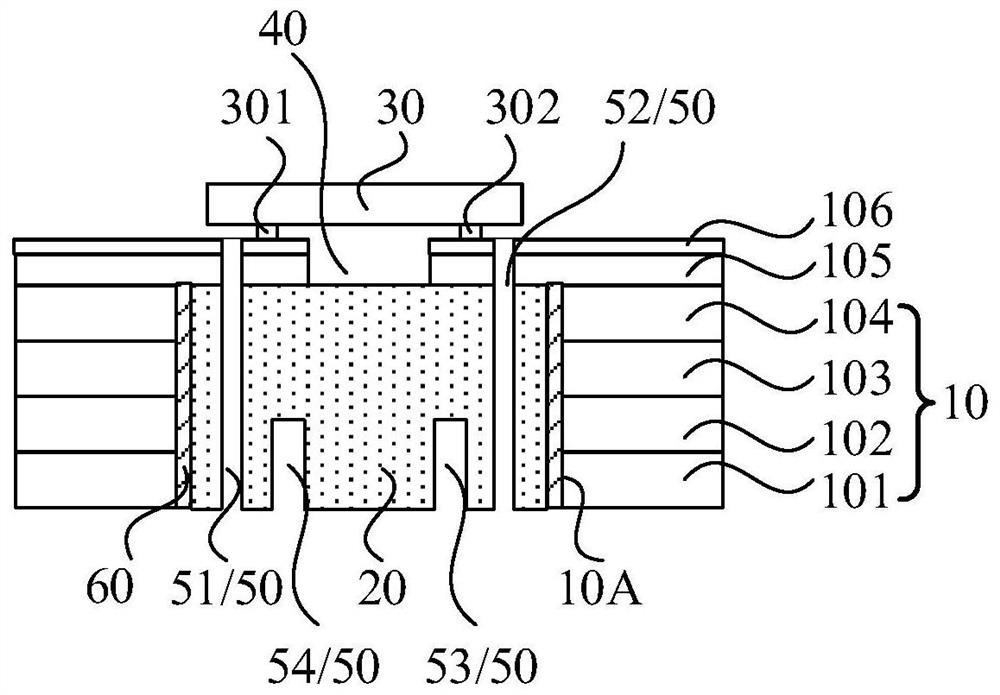

[0032] The embodiment of the present invention provides a high heat dissipation printed circuit board. see figure 1 , the high heat dissipation printed circuit board includes: a multilayer circuit board 10, a heat dissipation block 20, a laminate of an outer circuit layer 106 and a first insulating adhesive layer 105, and a heat source device 30; the multilayer circuit board 10 is provided with a second A through hole 10A; the heat dissipation block 20 is located in the first through hole 10A; the first insulatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap