Adhesive composition for protective film, adhesive comprising same and adhesive sheet using same

An adhesive and composition technology, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as excessive static electricity, and minimize the generation of static electricity The effect of reducing the peeling electrostatic voltage and improving the low-speed peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] The acrylic polymer is produced by polymerizing a second mixture of 87% by weight of 2-ethylhexyl acrylate (2-EHA) as the first monomer, 10% by weight of butyl acrylate (BA) monomer, 2.5% by weight 2-hydroxyethyl acrylate (2-HEA) as the third monomer and 0.5% by weight 4-hydroxybutyl acrylate (4-HEA) as the fourth monomer -HBA) obtained by mixing.

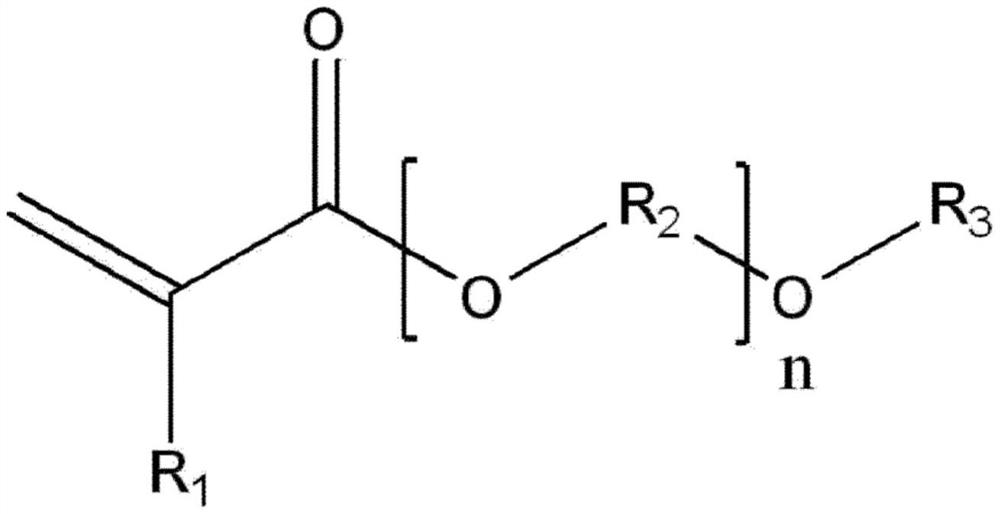

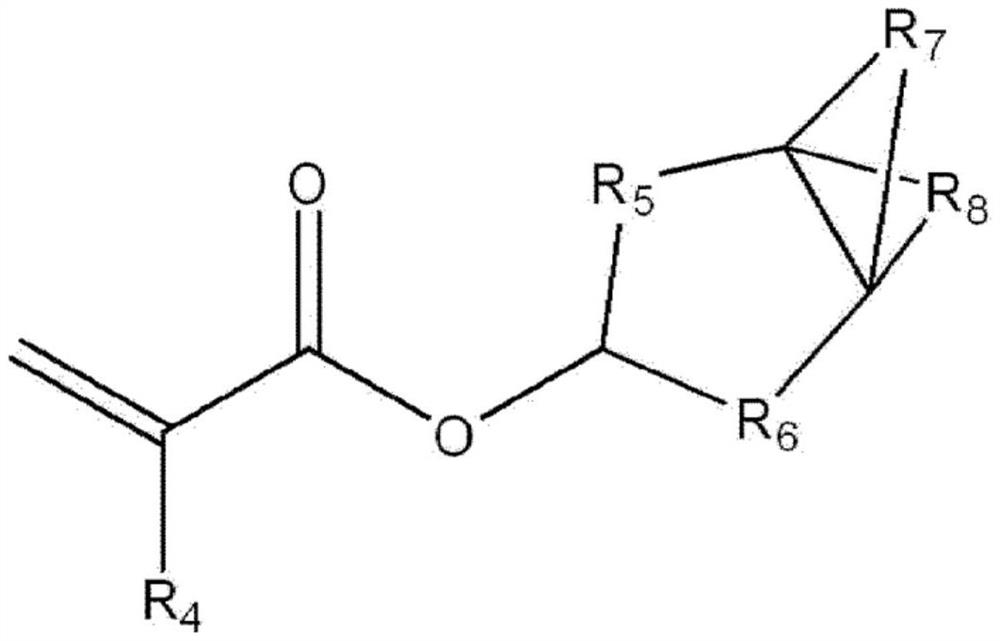

[0113] Thereafter, an oligomer-containing additive comprising a polymer of a first mixture by adding 30 parts by weight of methoxypolyethylene glycol methacrylate ( MPEGMA), 30 parts by weight of dicyclopentenyl methacrylate (DCPMA) as a second hydrophilic monomer, and 40 parts by weight of a fluorine-based monomer (Viscoat 13f).

[0114] Next, prepare the adhesive composition that is used for protective film, described adhesive composition is the acrylic polymer that comprises 100 weight parts, the bis(trifluoromethanesulfonyl) acrylic acid as antistatic agent of 0.2 weight part Lithium imide (LiTFSI), 0.5 parts by weight...

Embodiment 2

[0117] An adhesive sheet for a protective film was manufactured in the same manner as in Example 1 except that an adhesive composition for a protective film was prepared such that the content of the oligomer-containing additive therein was 0.3 parts by weight.

Embodiment 3

[0119] An adhesive sheet for a protective film was manufactured in the same manner as in Example 1 except that an adhesive composition for a protective film was prepared such that the content of the oligomer-containing additive therein was 0.5 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com