Spherical workpiece gripper with adjustable range

A spherical and workpiece technology, applied in the field of spherical workpiece grippers, can solve the problems of workpiece damage, difficult to adjust the angle of the jaws, and large gripping force, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments, it should be understood that these embodiments are used only to illustrate the present invention and not to limit the scope of the present invention, after reading the present note, those skilled in the art of various equivalent forms of modification of the present note are within the scope of the claims attached to the present application.

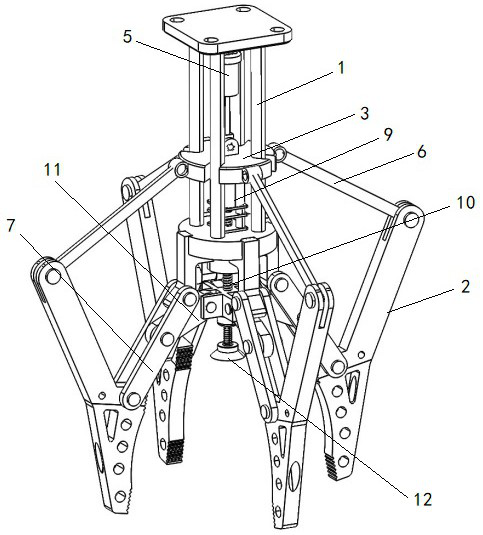

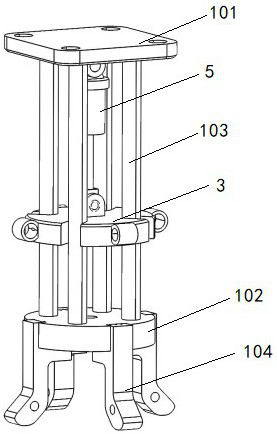

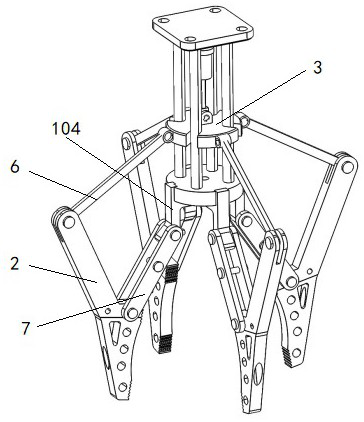

[0018] Please combine Figures 1 through 4 As shown, the adjustable range of the present embodiment of the spherical workpiece gripper comprises a pivot column 1 and four grippers around the axial column 1 is provided, the four grippers 2 are equally distributed around the axial column 1. Generally, the gripper 2 is set to at least three to stabilize the gripping of the spherical workpiece, and more than four grippers can also be set, and the increase of the gripper 2 makes the gripper parts increase, and the arrangement in the circumferential dir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap