High-flame-retardant foamed polypropylene production equipment with cooling and explosion-proof functions

A technology for foaming polypropylene and production equipment, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc. The effect of blanking blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

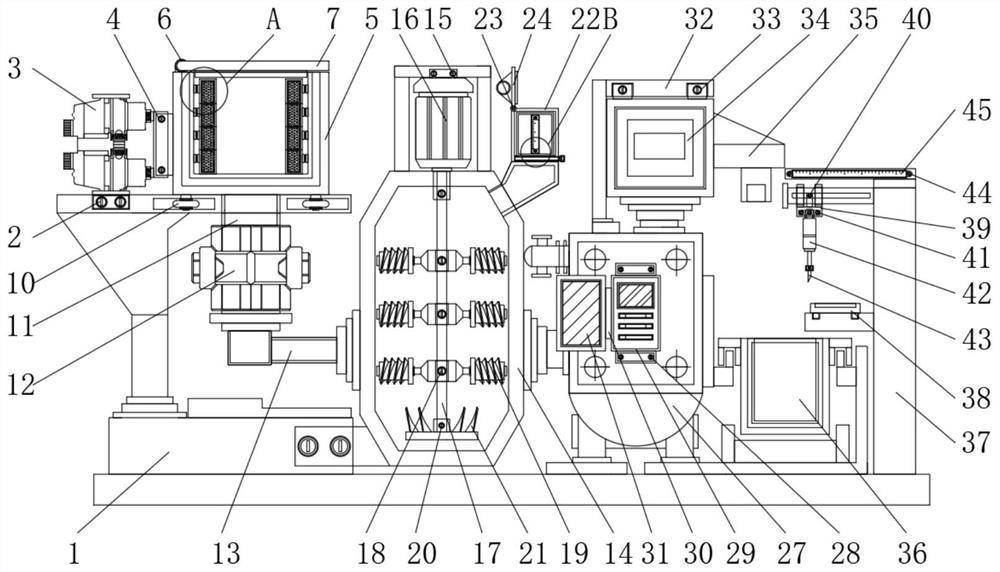

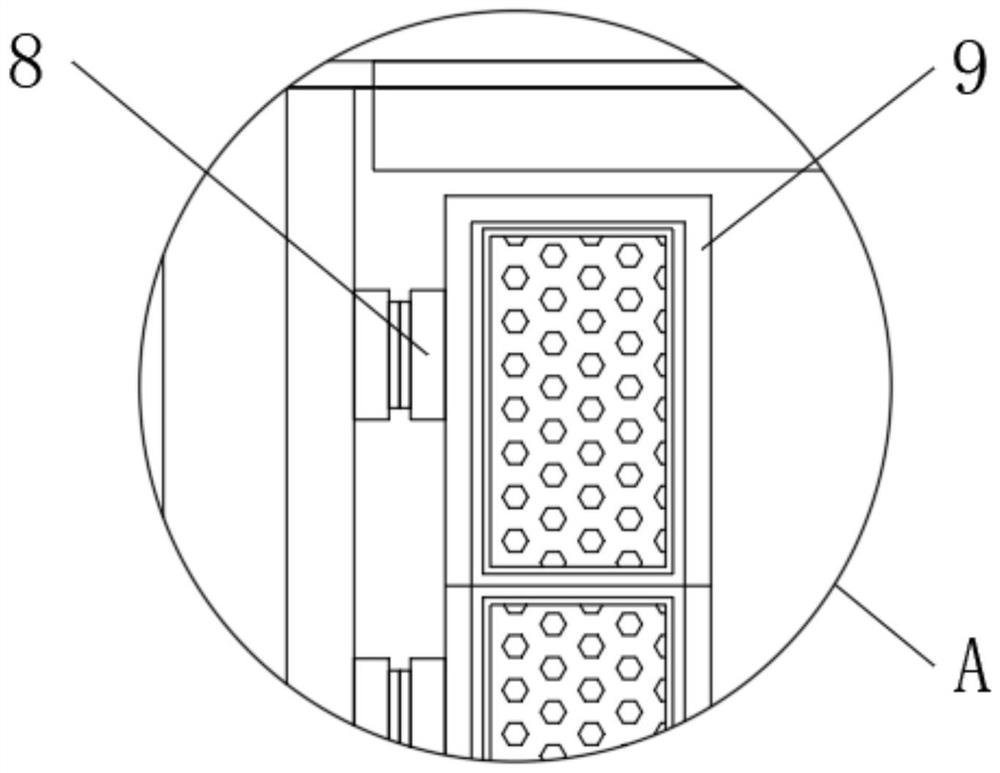

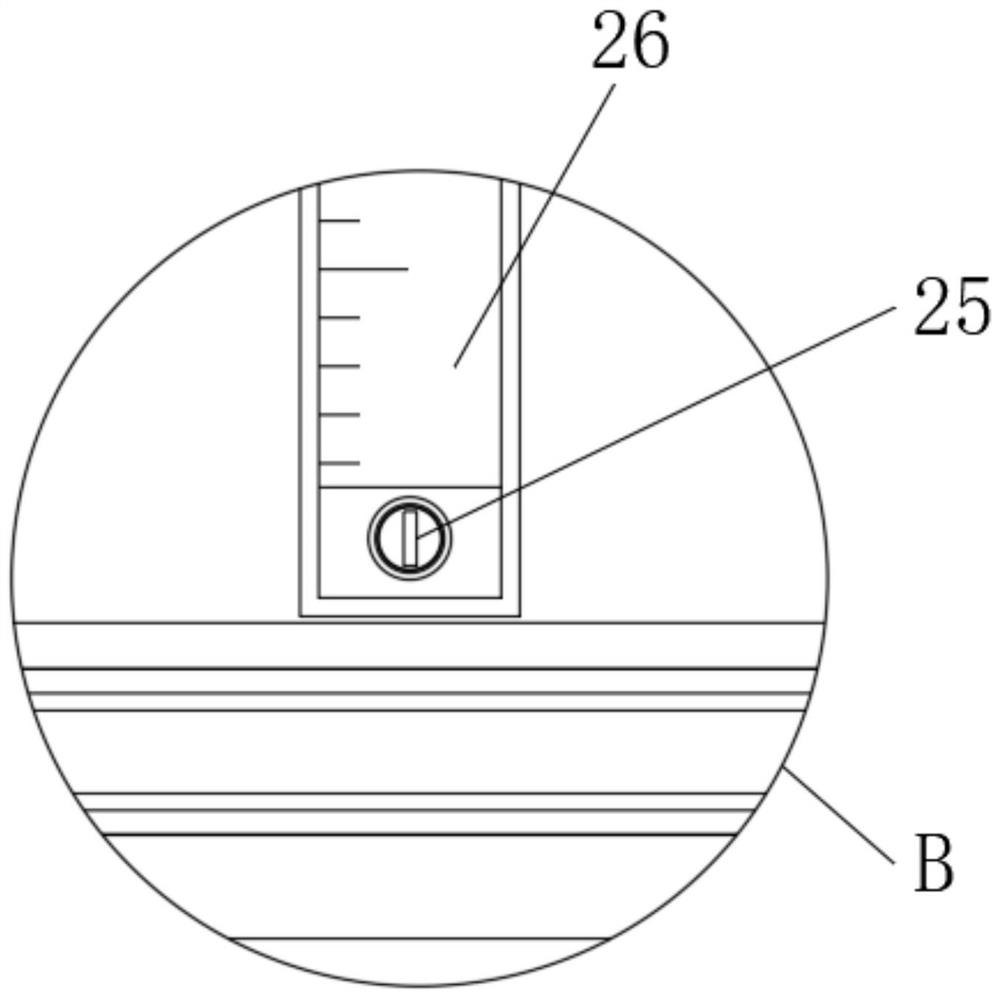

[0023] according to Figure 1-Figure 5As shown, the present embodiment provides a high flame retardant foam polypropylene production apparatus having a cooling explosion-proof function, comprising a base 1, the upper end of the base 1 is screwed with a first positioning rod 2, the outer wall screw of the first positioning rod 2 is connected to a vibration motor 3, the side screw of the vibration motor 3 is connected to the second positioning rod 4, the outer wall screw of the second positioning rod 4 is connected to the storage box 5, the upper end of the storage box 5 is installed with a first spindle 6, the upper end of the first rotating shaft 6 is installed with a first cover plate 7, The inner wall of the storage box 5 is installed with a magnetic block 8, the side of the magnetic block 8 is installed with a desiccant box 9, the lower end of the storage box 5 is installed with a rotary wheel 10, the lower end of the storage box 5 is installed with a transmission hose 11, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com