Multi-layer folding type label processing equipment

A kind of processing equipment and folding technology, applied in the direction of metal processing, etc., can solve the problems of low degree of automation, low production efficiency, and inability to carry out effective connection, so as to achieve the effect of improving the degree of automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

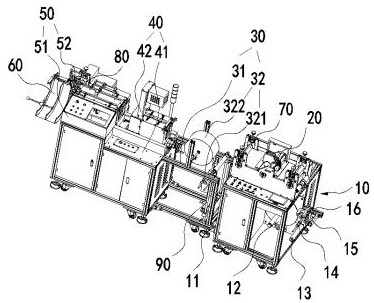

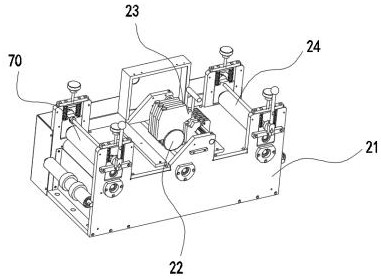

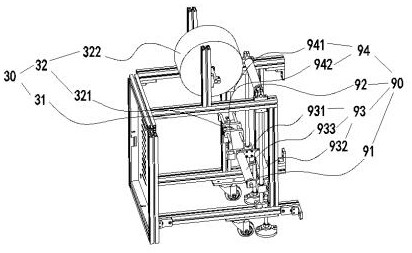

[0034] Please refer to figure 1 , a multi-layer folding label processing equipment, including a feeding mechanism 10, a slitting mechanism 20, a folding mechanism 30, an edge sealing mechanism 40, a cutting mechanism 50, a receiving assembly 60, a pulling shaft 70, a traction roller 80 and adjustment Component 90. The pulling shaft 70 is located between the slitting mechanism 20 and the folding mechanism 30, and the traction roller 80 is located between the edge sealing mechanism 40 and the cutting mechanism 50, and both the pulling shaft 70 and the traction roller 80 are driven by a motor.

[0035] Please refer to figure 1 , the feeding mechanism 10 includes a first support 11, a feeding tray 12, a third rotating shaft 13, a material-free sensor 14, a deviation correcting device 15 and a deviation correcting sensor 16, the discharging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com