Dispersion locking type rudderstock structure

A lock-type, rudder stock technology, which is applied in directions such as rudder steering and steering, can solve the problems of harsh machining accuracy, inflexible rudder stock assembly, limited use range, etc., and achieve the effect of improving radial structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

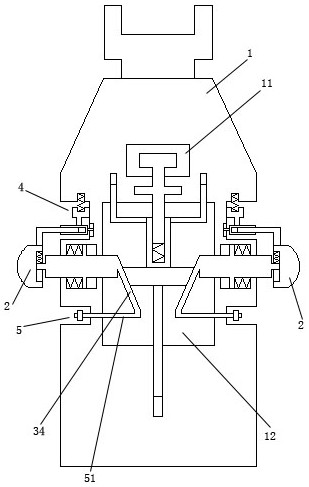

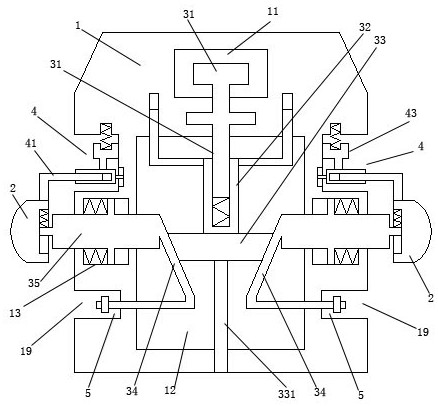

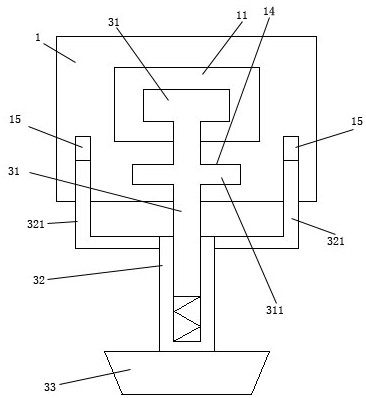

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Such as Figures 1 to 5 As shown, a decentralized locking rudder stock structure includes a rudder stock body 1, a floating bump 2, a radial adjustment mechanism 3, an axial adjustment mechanism 4, and a decentralized locking mechanism 5; the radial adjustment mechanism 3 includes an adjustment screw 31. Floating threaded barrel 32, pressing block 33, radial abutting plate 34, radial piercing column 35, radial pressing elastic body 36; the middle of the upper end of the rudder stock body 1 is provided with a drive groove 11; An adjustment cavity 12 is provided below the driving groove 11; a plurality of radial limiting passages 13 are evenly arranged around the adjustment cavity 12; The lower end of the screw rod 31 extends into the adjustment cavity 12 and is screwed to a floating threaded barrel 32; the floating threaded barrel 32 sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com