Nameplate marking machine

A marking machine and nameplate technology, applied in the field of marking machines, can solve problems such as low efficiency, high cost, and adverse human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

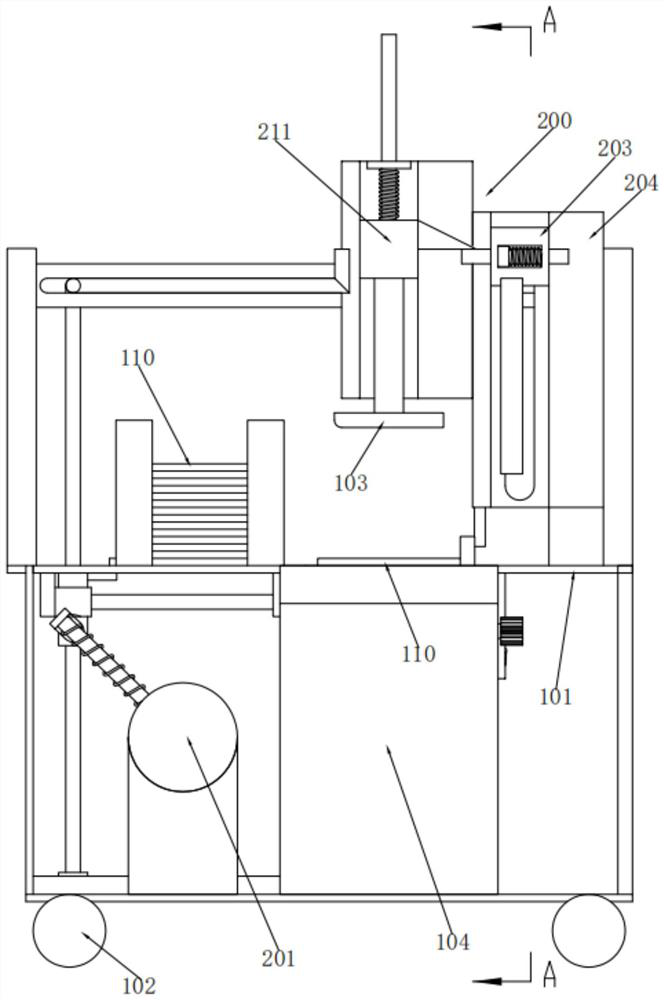

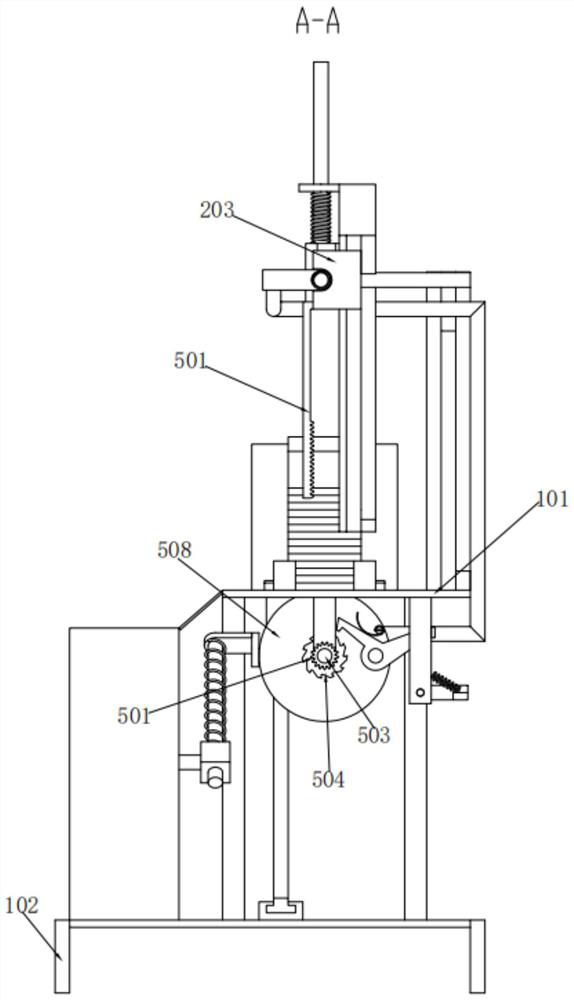

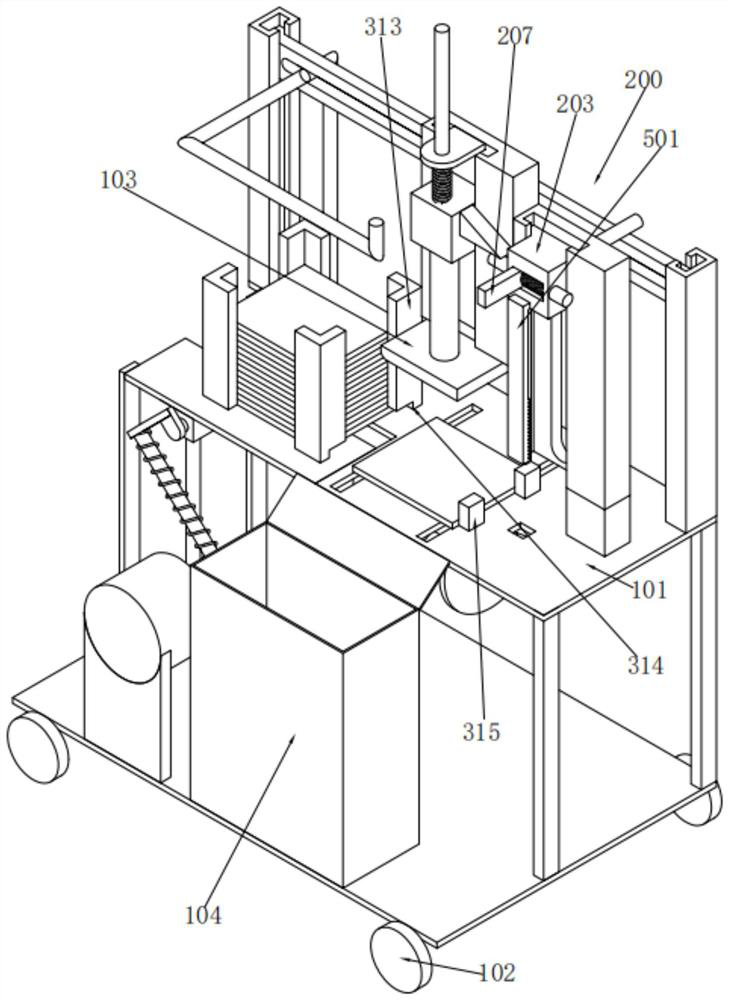

[0036] like Figures 1 to 10 shown, refer to figure 1 and Figure 5 , a nameplate marking machine including

[0037] The rack 101 has rollers 102 installed at its bottom;

[0038] A stamp 103, which is arranged on the rack 101;

[0039] A placement box 104, which is fixedly connected to the rack 101;

[0040] a switch 207, which is configured on the rack 101;

[0041] The marking mechanism 200 drives the slider lever mechanism through the motor 201 to move the steel stamp 103 upward, and manually controls the switch to complete the marking.

[0042] In the present invention, the marking mechanism 200 can be driven by the motor 201 to move the stencil 103 upward, and the stencil 103 can be automatically and quickly dropped by manually flipping the switch 207, and the characters to be marked are printed on the nameplate 110 to be marked, thereby realizing marking Function.

[0043] The power supply module of the motor 201 includes a battery, an electronic control module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com