Rope skipping prevention device for horizontal steel wire rope in tower crane and assembly method of rope skipping prevention device

A steel wire rope, horizontal technology, applied in the field of anti-skip rope device and its assembly, can solve problems such as wire rope breakage, wire rope skipping failure, pulley block damage, etc., to achieve the effect of easy replacement of parts, improvement of smoothness, and improvement of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

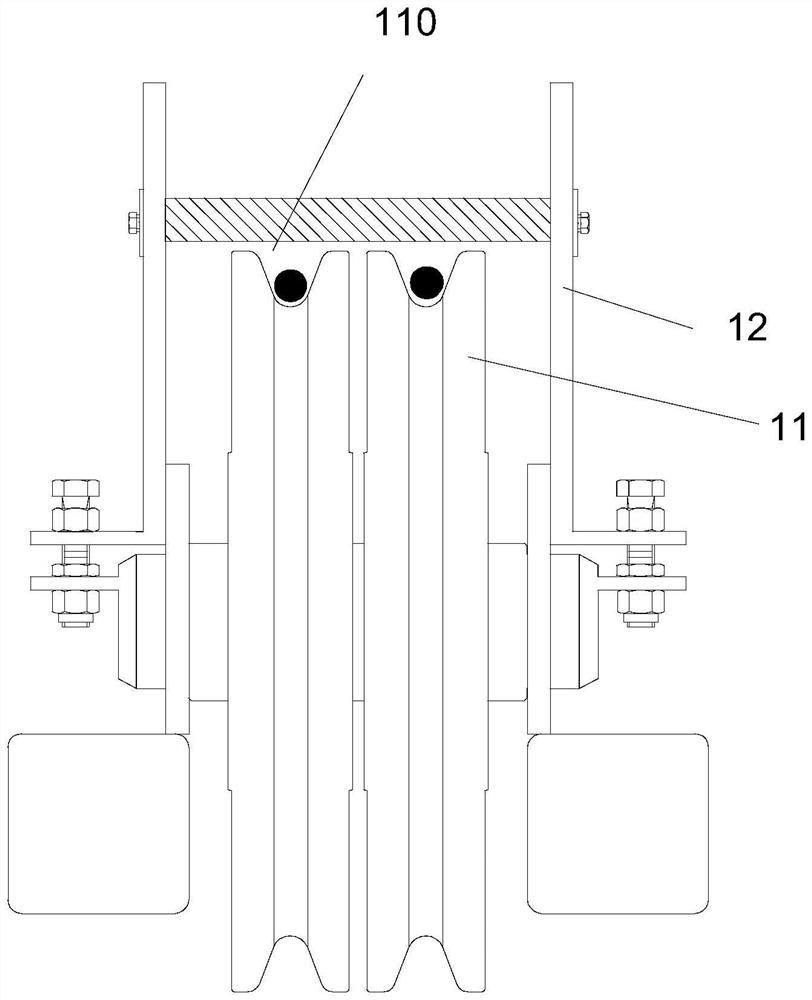

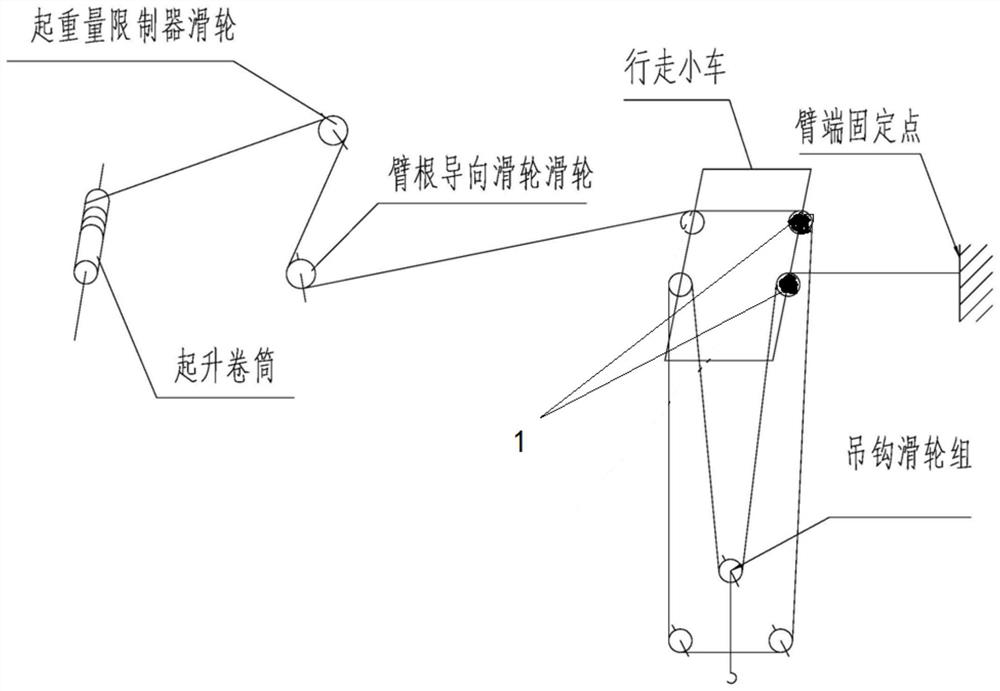

[0059] This embodiment is an anti-skip rope device for horizontal wire ropes in a tower crane, which is installed at the steering pulley block 1 in the traveling trolley of the tower crane; figure 2 Shown is a diverting pulley block 1 for converting the direction of wire rope extension from vertical to lateral. The anti-skip rope device can prevent the wire rope from skipping or fraying in this place.

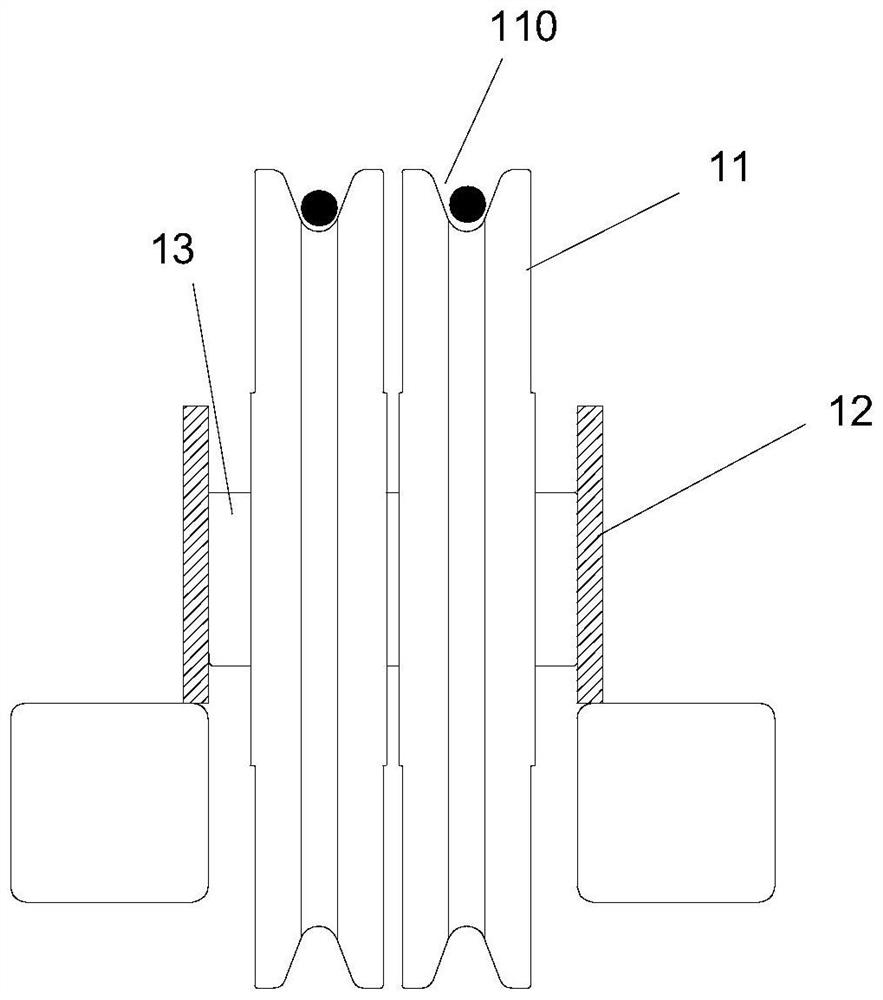

[0060] like image 3 As shown, the steering pulley block 1 on which the anti-skip rope device is installed includes a fixed pulley 11 , an axle 13 and a clamping plate 12 clamped on both sides of the fixed pulley 11 . The wheel body of the fixed pulley 11 includes a first rope groove 110 for accommodating the wire rope in the circumferential direction. The cross section of the first rope groove 110 is in the shape of a "normal distribution curve" with an upward opening, and the bottom of the first rope groove 110 is a semicircle matching the outer contour of the wire rope. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com