Air flow measuring method based on bell mouth flow tube speed distribution model

A speed distribution and air flow technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of multiple measuring point layout and high cost, reduce the number of measuring points, accurately arrange them, improve flow measurement accuracy and measurement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

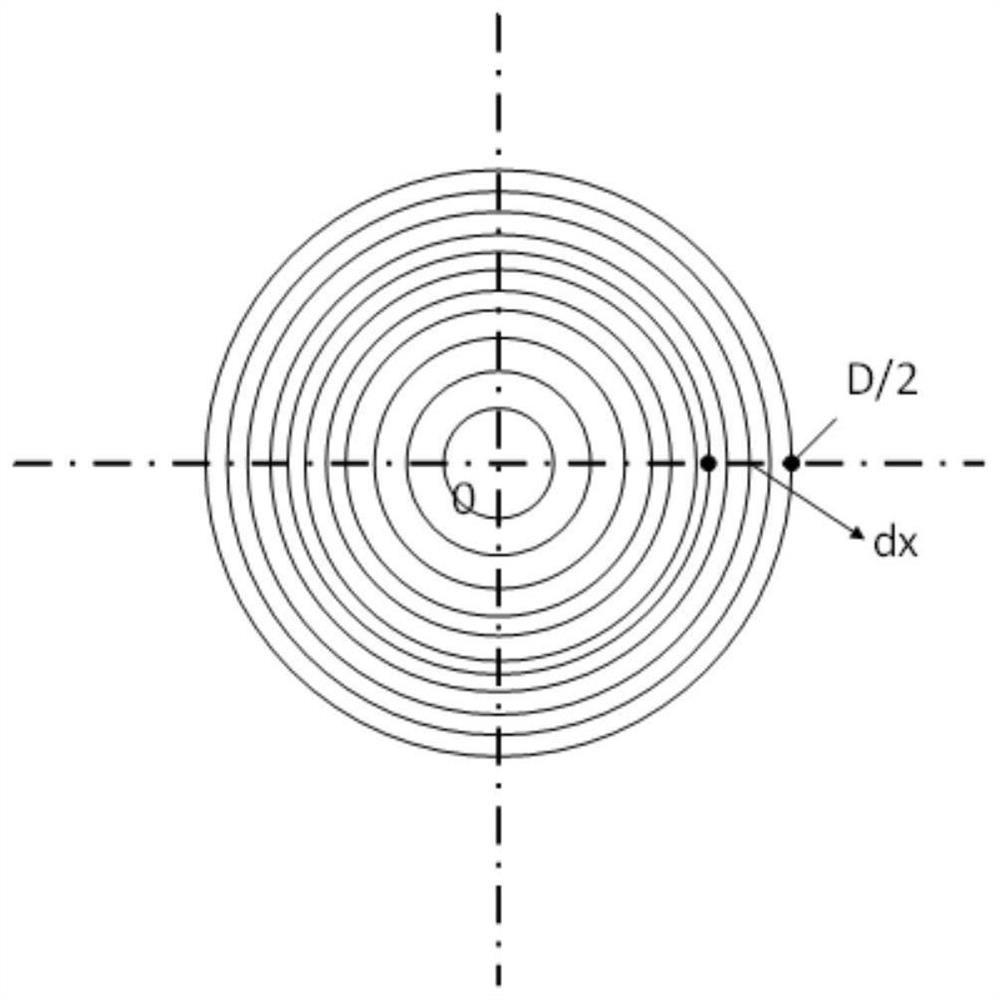

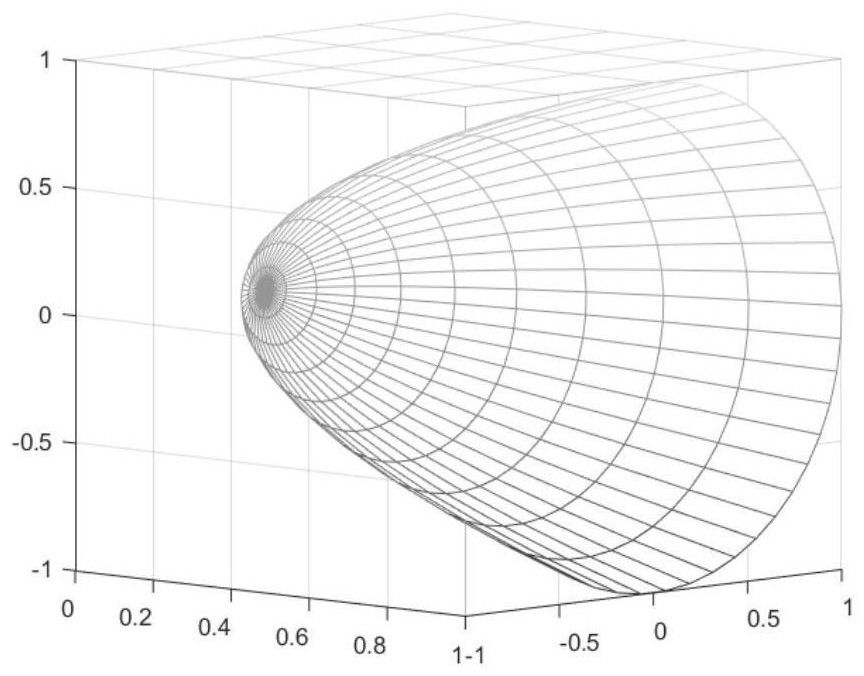

[0060] In order to solve the problem of many measuring points when using the bell-shaped flow tube to accurately measure the air flow, the diameter of the pipe is D=400mm, the profile section is a twisted pair profile, and the polar coordinate formula of the twisted pair is ρ 2 =r 2 In cos 2θ, r is taken as 0.637D, and a bell-shaped flow tube with a flanging structure of 40mm is taken as an example, and the on-site air flow measurement process using this bell-shaped flow tube is described. At the same time, the annular area method was used to measure the air flow under the same flow state, and the two results were compared and analyzed.

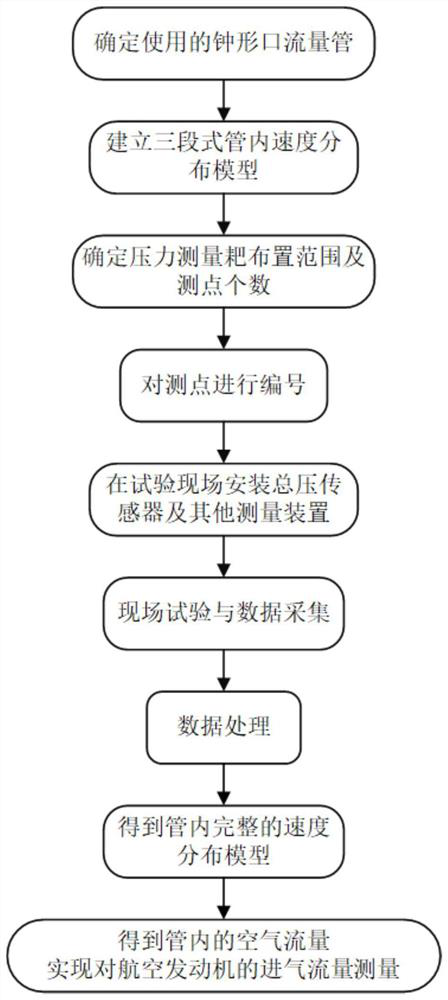

[0061] like figure 1 As shown, the specific implementation steps of the flow measurement method based on the velocity distribution model of the bell-shaped flow tube disclosed in this embodiment are as follows:

[0062] Step 1: For the bell-shaped flow tube used, establish a velocity distribution model in the tube, and determine the arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com