Ternary cathode material and preparation method thereof

A technology of cathode materials and precursors, applied in the field of ternary cathode materials and their preparation, can solve the problems of increasing the production cost of ternary cathode materials, unpleasant smell, etc., and achieve good automatic dispersion effect, low cost and high reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the ternary positive electrode material provided in the embodiment of the present application includes:

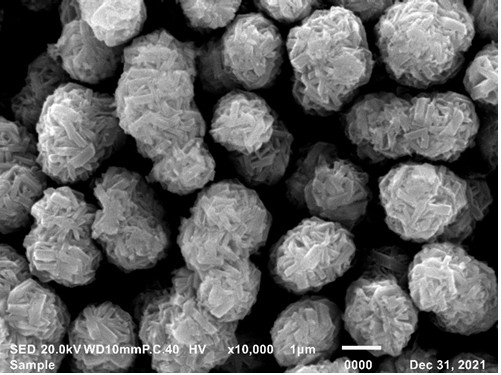

[0041] The alkaline solution with hydroxide concentration ≥10mol / L and the precursor metal salt solution with concentration ≥2mol / L are based on the molar ratio of hydroxide in the alkaline solution to the metal ion in the precursor metal salt solution ≥ 2 Mixing, mixing and reacting for 2~60min, after the reaction is over, remove the moisture from the obtained precipitate to obtain a ternary precursor nano-powder.

[0042] The lithium hydroxide and the ternary precursor nano-powder are mixed for spheroidization, and the ternary precursor nano-powder is supported on the lithium hydroxide particles to obtain primary particle materials.

[0043] The primary particulate material is sintered.

[0044] A high concentration alkaline solution is used to react with a high concentration precursor metal salt solution, and the reaction time is contro...

Embodiment 1

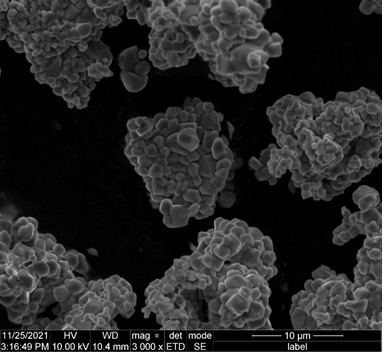

[0070] The same volume of 20mol / L sodium hydroxide solution and 2.5mol / L nickel-cobalt-manganese sulfate mixed solution (molar ratio Ni / Co / Mn=5 / 2 / 3) were rapidly mixed at 60°C, and the mixed reaction was carried out. For 30 s, after the reaction is completed, the ternary precursor nano-powder is obtained by pressure filtration, washing and vacuum drying, wherein the drying temperature is 120°C.

[0071] The lithium hydroxide particles with D50=500 μm and the ternary precursor nano-powder obtained in the above steps are mixed according to Li / Me of 1, and placed in a fusion machine. The process parameters of the fusion machine during fusion are set as: feeding 50rpm / min ; mixing at 350 rpm / min for 5 min; fusion at 800 rpm / min for 20 min; intensive fusion at 1000 rpm / min for 3 min; discharging at 50 rpm / min to obtain a ternary cathode material.

Embodiment 2

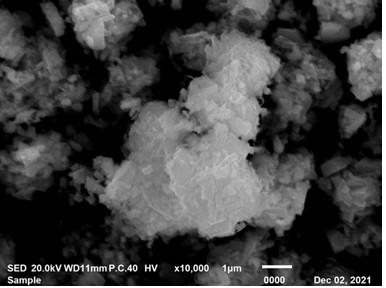

[0073] The same volume of 4mol / L sodium carbonate solution and 2.5mol / L nickel-manganese sulfate mixed solution (molar ratio Ni / Mn=1 / 3) were rapidly mixed at 60°C, and the mixing reaction was carried out for 5 minutes. Pressure filtration, washing, and vacuum drying, wherein the drying temperature is 150° C. to obtain ternary precursor nano-powder.

[0074] The lithium hydroxide particles with D50=500 μm and the ternary precursor nano-powder obtained in the above steps are mixed according to Li / Me of 1, and placed in a fusion machine. The process parameters of the fusion machine during fusion are set as: feeding 50rpm / min ; Mixing 350 rpm / min, 5min; Fusion 800 rpm / min, 20min; Intensive fusion 1000 rpm / min, 3min; Discharge 50rpm / min. A ternary positive electrode material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com