Cable pulling and arranging equipment

A cable and pull wire technology, applied in the field of cable pull and wire arrangement equipment, can solve the problems of cumbersome cable tray construction process, and achieve the effects of avoiding separation from the cable tray, wide application range, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

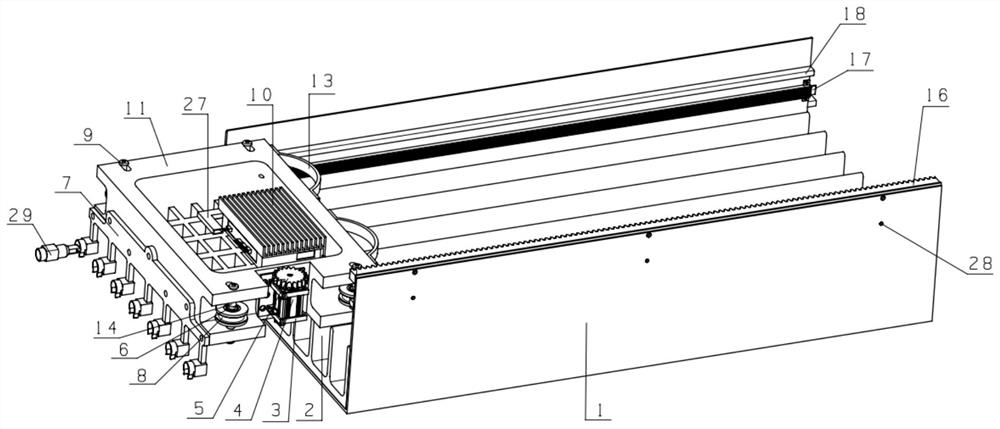

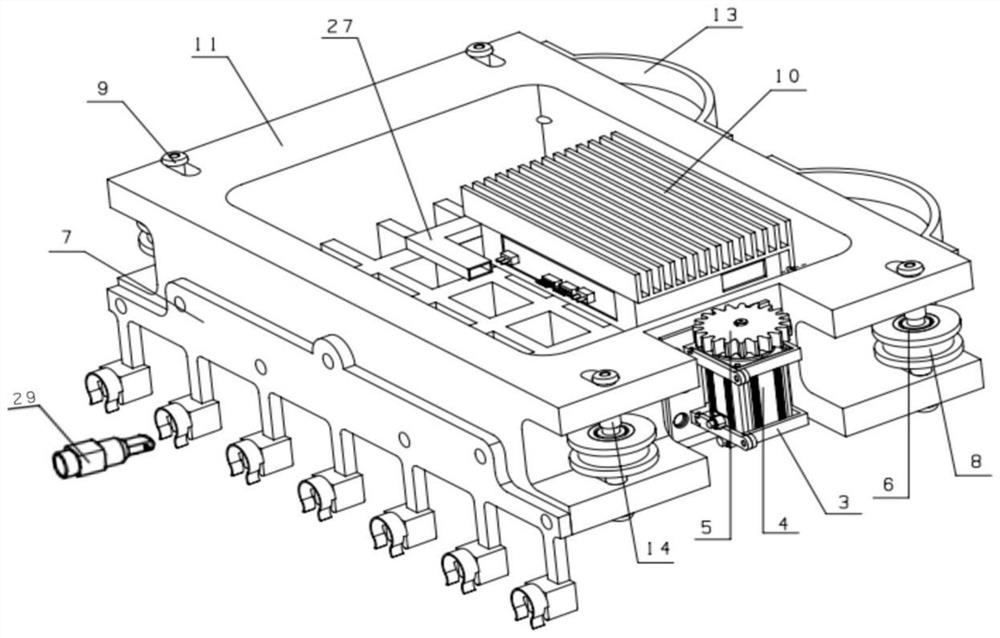

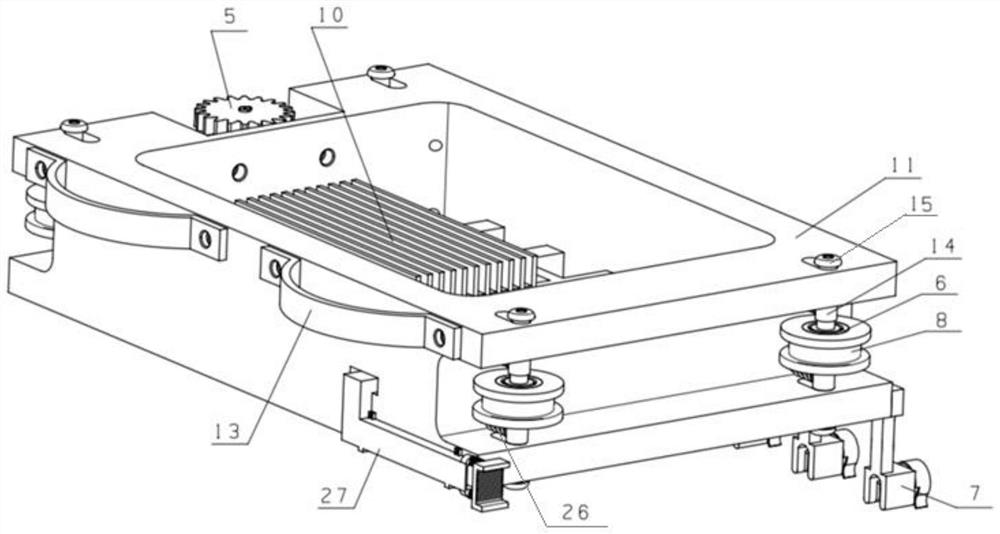

[0046] Embodiment 1: A kind of cable drawing line arrangement equipment (see Figure 1-5 ), including the cable tray body 1 and the guide rail slider trolley 11,

[0047] The bottom of the cable tray body 1 is evenly provided with several wire grooves 2 along the extension direction of the bridge frame. A rack 16 is arranged on one side wall of the cable tray body 1 along the extension direction of the bridge frame. Guide rails 18 are arranged opposite to the extending direction of the bridge;

[0048] The outer walls on both sides of the guide rail slider trolley 11 are provided with grooved wheels 8, and the guide rail 18 on the cable bridge body 1 is embedded in the groove of the grooved wheel 8 corresponding to the grooved wheel 8, and the grooved wheel 8 is rollingly connected with the guide rail 18. The side end of the guide rail slider trolley 11 is provided with a servo motor 4, the output shaft of the servo motor 4 is provided with a gear 5, the gear 5 is engaged wit...

Embodiment 2

[0050] Embodiment 2: The structure of the cable pulling and arranging equipment in this embodiment is basically the same as that of the cable pulling and arranging equipment in Embodiment 1. A plurality of pin slots, the end of the cable is fixedly provided with a line card 29, and the line card 29 is stuck in the pin slot of the wire pulling device 7;

[0051] Tightening bolts passing through the wall of the line card are evenly arranged on the line card 29 along the circumferential direction, and the ends of the cables can be fixed in the line card 29 by tightening the bolts;

[0052] The staff only need to plug the end of the cable into the line card 29, and then adjust the tightness of the tightening bolts to fix the end of the cable in the line card 29, and then pass the line card 29 and the pin card of the puller device 7 The slots are clamped to realize the fixed connection between the cable end and the wire pulling device 7 of the guide rail slider trolley 11.

Embodiment 3

[0053] Embodiment 3: The structure of the cable pulling and arranging equipment in this embodiment is basically the same as that of the cable pulling and arranging equipment in Embodiment 2, except that:

[0054] The servo motor 4 is arranged on the side end of the guide rail slider trolley 11 through the motor frame 3;

[0055] The motor frame 3 comprises a base plate, a top plate and a cylinder, and the side ends of the base plate and the top plate are fixedly arranged on the side ends of the guide rail slider dolly 11, and the four corners of the base plate and the top plate are fixedly connected by the cylinder, and the base plate is fixedly provided with a horizontal slideway 1 , the bottom end of the top plate is fixedly provided with a horizontal slideway II, the horizontal slideway I and the horizontal slideway II are parallel and perpendicular to the rack 16, the bottom end of the servo motor 4 is fixedly provided with a horizontal slide block I, and the top end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com