Multipurpose cleaning tank of endoscope cleaning workstation

A technology for cleaning tanks and workstations, applied in the field of multi-purpose cleaning tanks, can solve problems such as manual grasping of electronic endoscopes, and achieve the effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

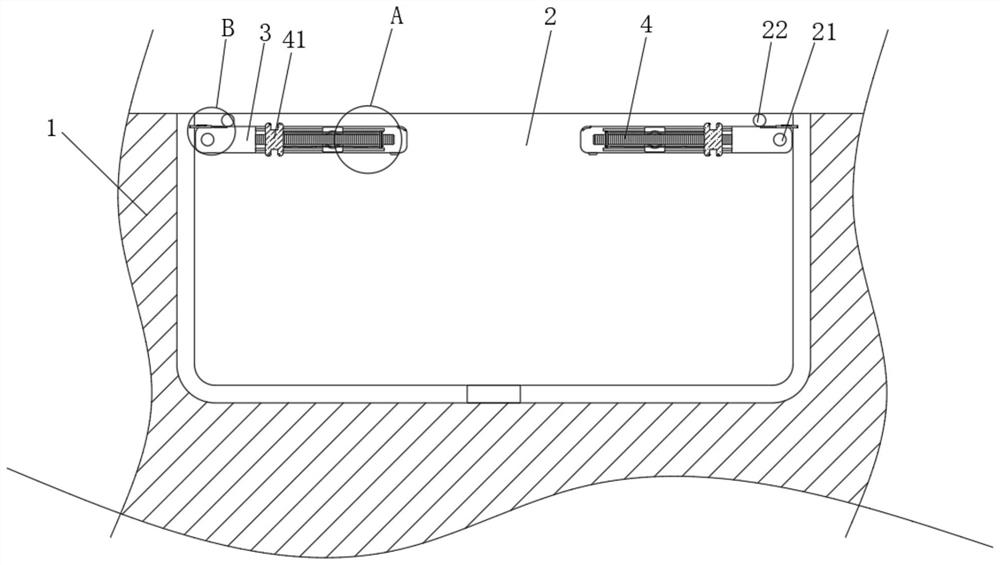

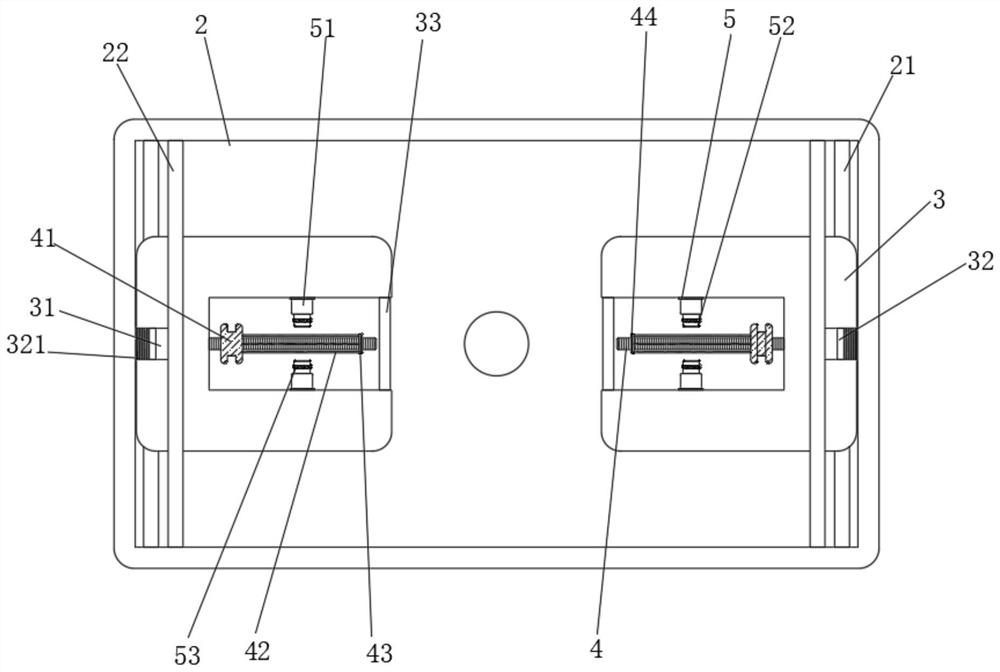

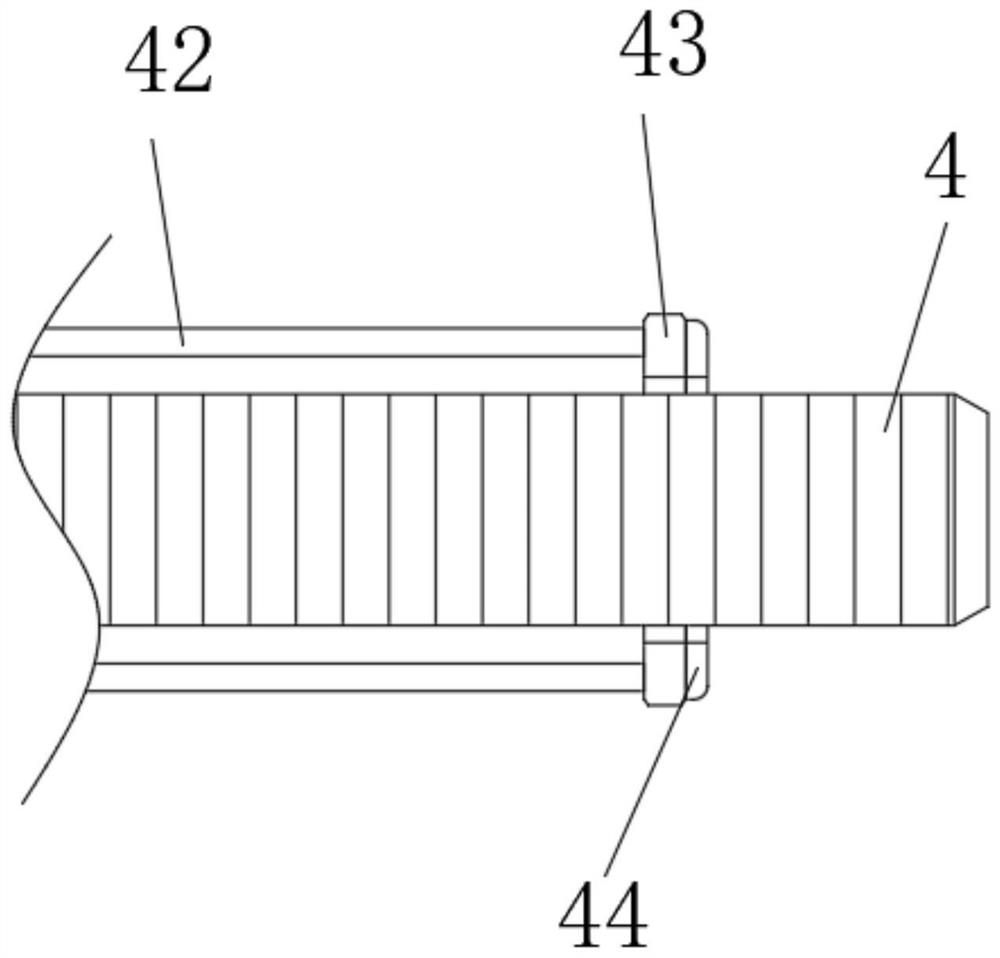

[0035] Example 1: see Figure 1-5, the multi-purpose cleaning tank of the endoscope cleaning workstation of the present invention includes a cleaning table 1, a cleaning tank 2, a connecting plate 3, a threaded rod 4 and a sliding plate 5, and the interior of the cleaning tank 2 is integrally formed with two first connecting rods 21, The connecting plate 3 is sleeved on the outside of the first connecting rod 21 , the surface of the connecting plate 3 is provided with an opening, the threaded rod 4 is fixedly connected to the surface of the connecting plate 3 , and the nuts 41 corresponding to the outside of the threaded rod 4 are located on the connecting plate 3 At the inner position of the opened opening, the front and back of the nut 41 leave space between the opening and the connecting plate 3 respectively. The nut 41 is designed with a circular structure and a limiting groove is provided along the outer side of the ring. The surface of the nut 41 is engraved with The sur...

Embodiment 2

[0036] Example 2: Unlike Example 1, see Figure 1-5 , slots 23 are provided on both sides of the inner wall of the cleaning tank 2, and a chute 31 is provided on the top surfaces of the two connecting plates 3 and at positions close to one side away from each other. The convex plate 32 in the groove 23, the top surface of the convex plate 32 runs through a plurality of grooves 321 along the horizontal longitudinal direction, and the bottom surfaces of the two connecting plates 3 and the positions close to the opposite surfaces are fixedly connected with a first rubber pad 35, When adjusting the state between the connecting plate 3 and the cleaning tank 2, the medical staff can use the groove 321 opened on the top surface of the convex plate 32 to slide the convex plate 32 inward, so that the convex plate 32 is connected to the cleaning tank. The slots 23 opened in 2 are separated, so that the connection plate 3 and the cleaning tank 2 are in a loose state, and then the connect...

Embodiment 3

[0037] Example 3: Unlike Example 1 or 2, see Figure 1-5 , the inner wall of the cleaning tank 2 is integrally formed with two limit rods 22, the surfaces of the limit rods 22 are respectively in contact with the top surfaces of the two connecting plates 3, and the surface of the connecting plate 3 is close to the opening. A fixed plate 33 is fixedly connected, and the corners of the fixed plate 33 are all designed in a smooth shape. The surface of the fixed plate 33 is set as a smooth surface. When the connecting plate 3 needs to be used, the medical staff can grasp the fixed plate 33. Press and turn over so that the top surface of the connecting plate 3 is in contact with the limiting rod 22 , and then use the convex plate 32 to limit the space between the connecting plate 3 and the cleaning tank 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com