Method for quickly changing upper supporting roll of hot continuous rolling mill

A back-up roll and rolling mill technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of long time-consuming maintenance or replacement of the upper back-up roll, high strength, low efficiency, etc., so as to reduce consumption time, reduce the replacement steps, and improve the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

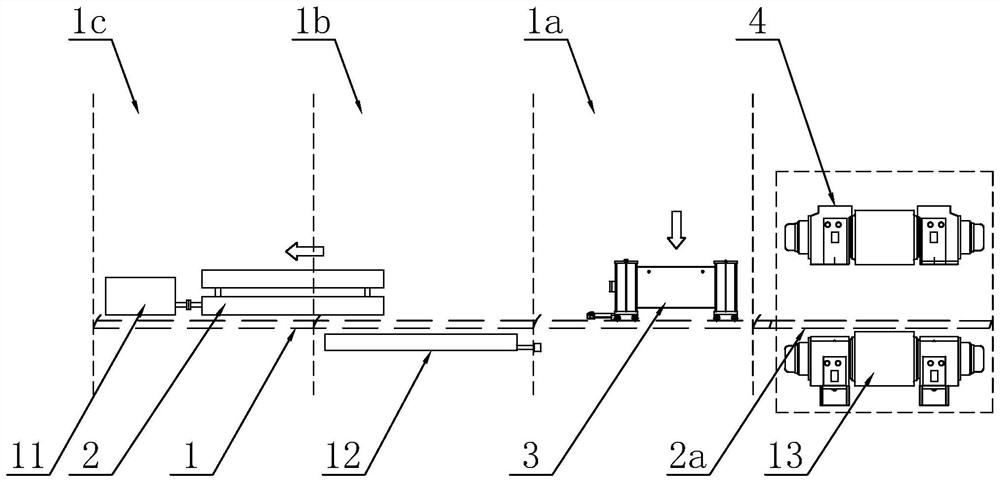

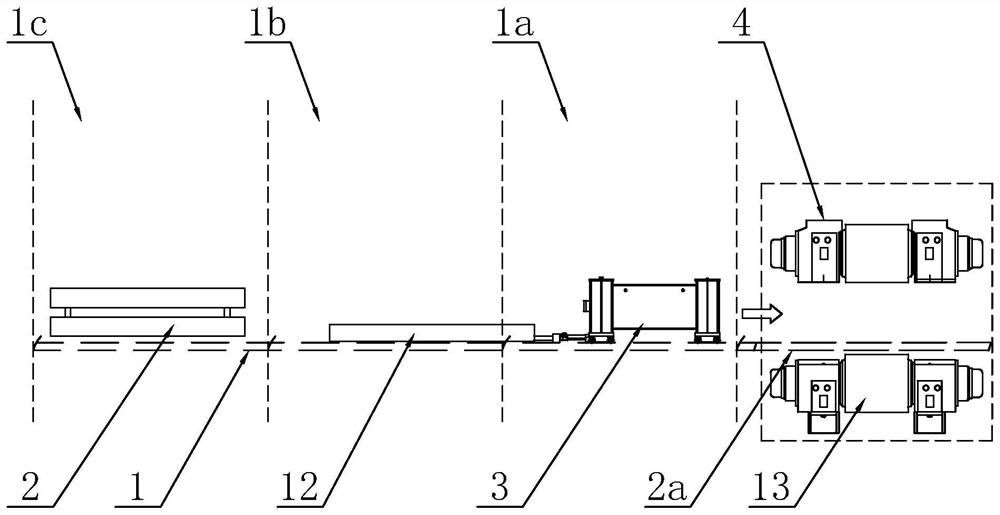

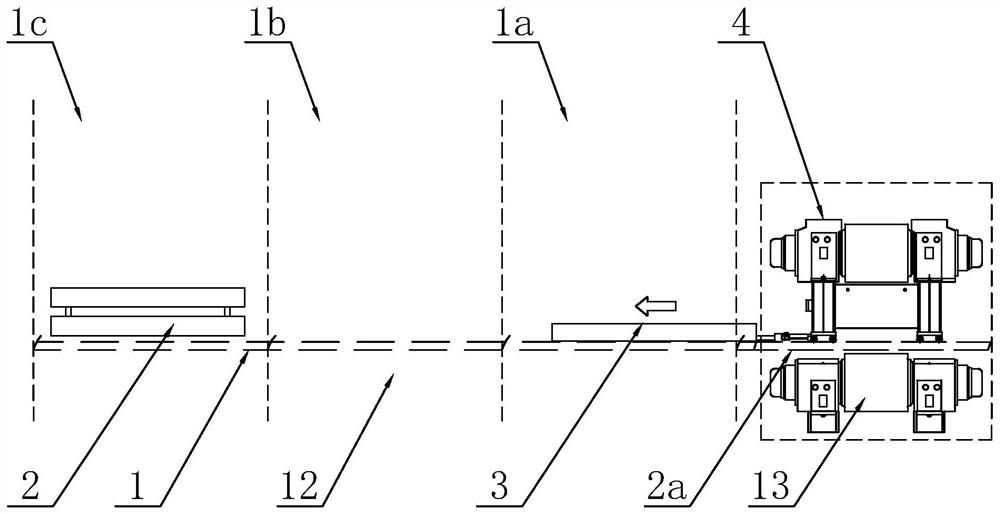

[0041] like figure 1 , 2 , 3 and 4: A method for quick change of backup rolls on a hot tandem rolling mill, which is carried out according to the following steps:

[0042] S1 The roll changing platform works, the roll changing platform track 1 is horizontally connected to the work roll track 2a, the locking cylinder is retracted, the lock of the work roll 2 is released, and the work roll 2 is pulled out of the rolling mill body along the track through the push-pull device 12 to the roll changing platform. Position 1a, and then pull the work roll 2 along the track to the standby roll position 1c at the rear of the roll changing platform through the push-pull trolley 11, and release the connection of the components of the upper backup roll 4.

[0043] S2 hoist the quick change device 3 to the roller changing position 1a of the roller changing platform track 1 by traveling.

[0044] S3 turns the push-pull device 12 of the push-pull position 1b out of the roller changing platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com