Forging and pressing piece heat treatment device

A heat treatment device and forging technology, which is applied in forging/pressing/hammer devices, heat treatment equipment, quenching devices, etc., can solve the problem that there is no way to realize the reciprocating forging of workpieces, and achieve the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

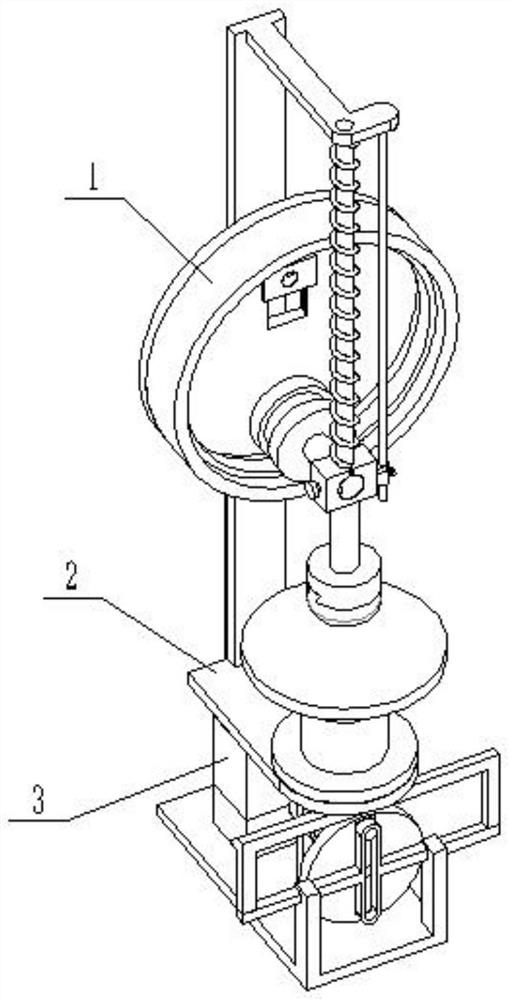

[0031] like Figure 1-12 As shown, a heat treatment device for a forging piece includes a biaxial motor 3, a driving belt 4 is connected to the biaxial motor 3, a forging assembly 1 is installed on the driving belt 4, and the lower end of the forging assembly 1 is provided with an epicyclic assembly 2, A liquid spray assembly 5 is installed on the turnover assembly 2, and this arrangement is convenient to provide driving power to the forging assembly 1 and the turnover assembly 2 through the biaxial motor 3; it is convenient to realize the forging of the workpiece through the forging assembly 1, and can be adjusted according to the actual situation. The forging range can be adjusted to adjust the forging efficiency of the workpiece; the turnover component 2 can drive the workpiece to reciprocate, so that the forging component 1 can achieve uniform forging of the workpiece; the forging component 1 drives the liquid spray component 5 during forging The gap between the parts real...

Embodiment 2

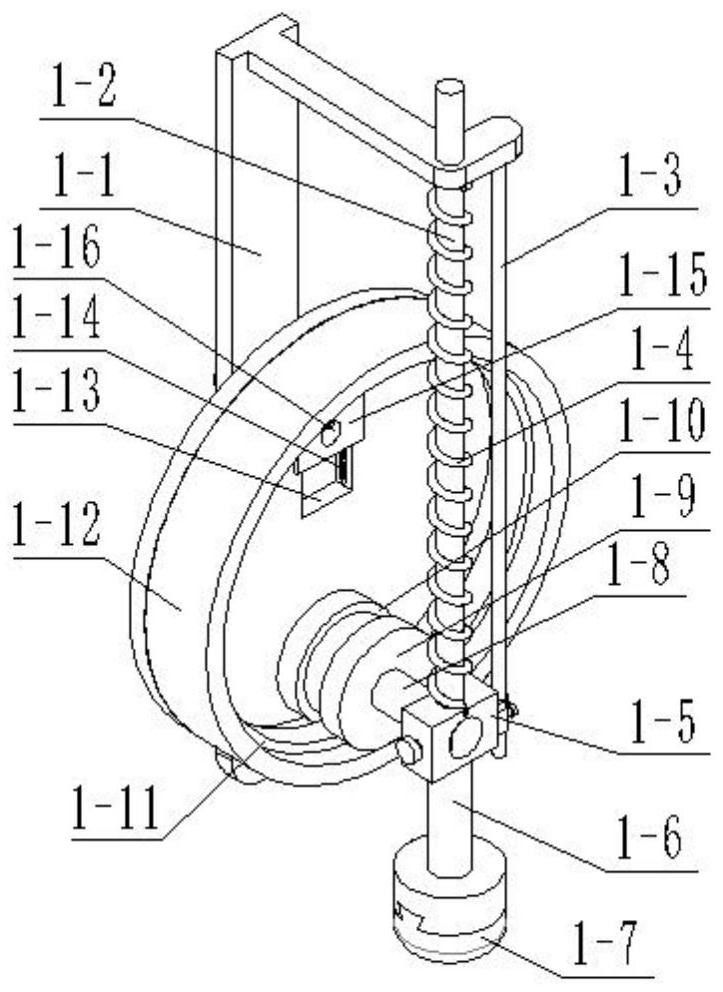

[0033] like Figure 1-12As shown, the forging assembly 1 includes a forging bracket 1-1, a connecting slide bar 1-2, an auxiliary slide bar 1-3, a spring one 1-4, a connecting block 1-5, a mounting rod 1-6, and a hammer head 1 -7. Drive rod 1-8, drive roller 1-9, annular groove 1-10, inner end convex edge 1-11, drive plate 1-12, rectangular chute 1-13, positioning slot 1- 14. Drive slider 1-15, rotating rod 1-16, positioning clamp one 1-17, positioning clamp rod push spring one 1-18, positioning screw one 1-19, positioning screw two 1-20, installation sleeve 1-21 and mounting screws 1-22, the forging bracket 1-1 is fixedly connected with the connecting slide bar 1-2, the auxiliary slide bar 1-3 is fixedly connected with the forging bracket 1-1, and the spring one 1-4 is connected with the connecting slide bar. Rods 1-2 are sleeved and connected, the connecting blocks 1-5 are fixedly connected with the connecting sliding rods 1-2, the springs 1-4 are arranged between the conne...

Embodiment 3

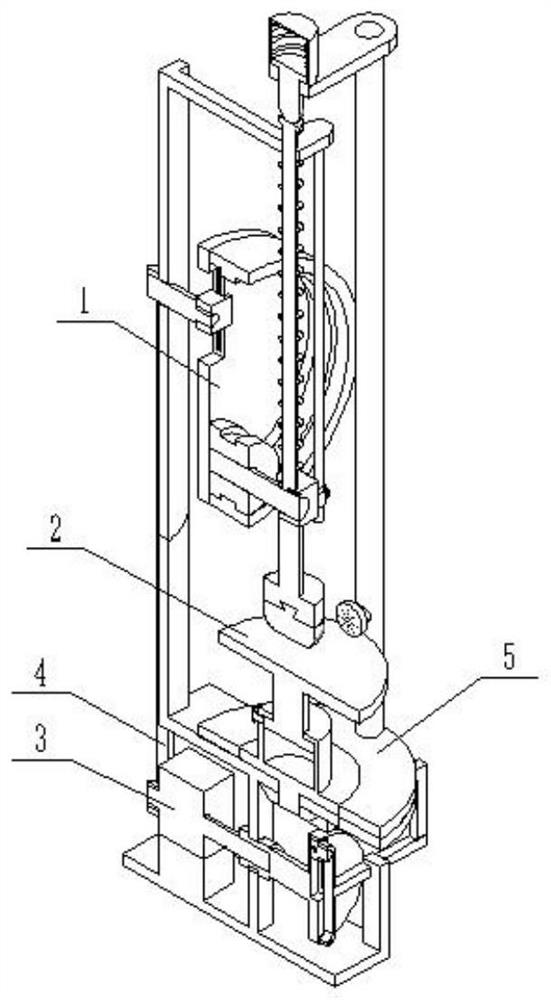

[0035] like Figure 1-12 As shown, the epicyclic assembly 2 includes an epicyclic support 2-1, a side wall support 2-2, a driving sliding rod 2-3, a connecting rod 2-4, a driving rack rod 2-5, a rotating sleeve 2-6, a forging Platform 2-7, lower drive plate 2-8, drive bevel 2-9, drive lever 2-10, lower rectangular chute 2-11, drive slider 2-12, matching slot 2-13, matching The clamping rod push spring 2-14, the matching clamping rod 2-15 and the locking screw 2-16, the side wall bracket 2-2 is fixedly connected with the turnover bracket 2-1, and the driving sliding rod 2-3 is connected with the side wall bracket 2 -2 sliding connection, one end of the connecting rod 2-4 is installed on the driving sliding rod 2-3, the other end of the connecting rod 2-4 is installed on the driving rack rod 2-5, the rotating sleeve 2-6 is connected with the epicyclic bracket 2 -1 Rotating connection, the forging platform 2-7 is slidingly connected with the rotating sleeve 2-6 and is positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com