Rail-mounted overhead rail robot multi-machine scheduling method

A technology of orbital robots and robots, applied in manipulators, manufacturing tools, comprehensive factory control, etc., can solve problems such as low efficiency and difficulty in bending space orbits, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

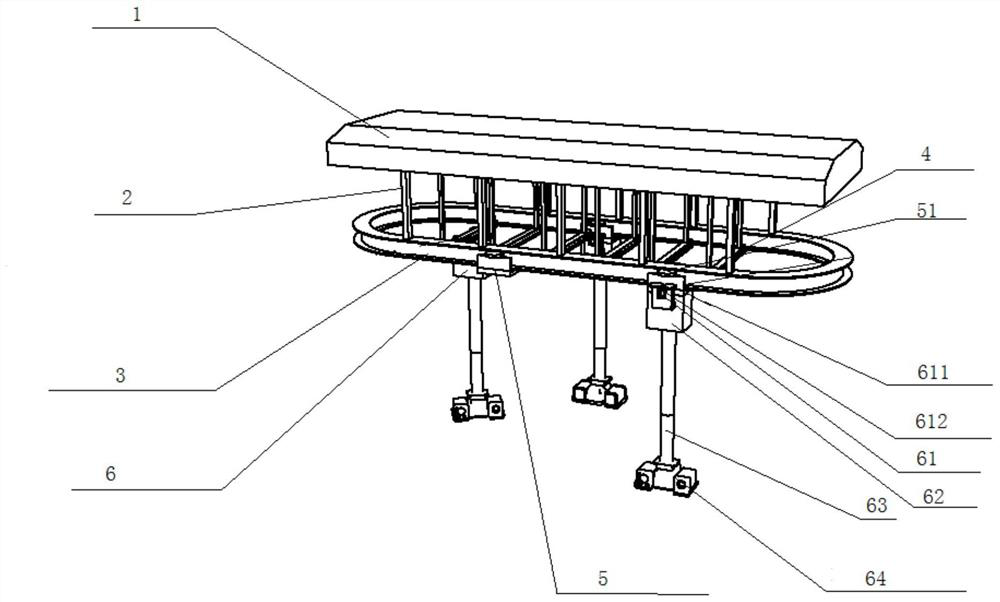

[0032] The invention provides a multi-machine scheduling method for a rail-mounted rail-hoisting robot, which utilizes rails and rail-carrying robots to schedule and run multiple rail robots.

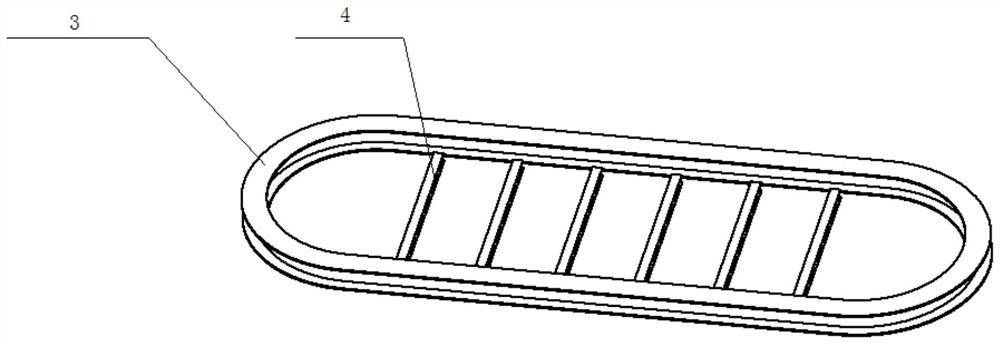

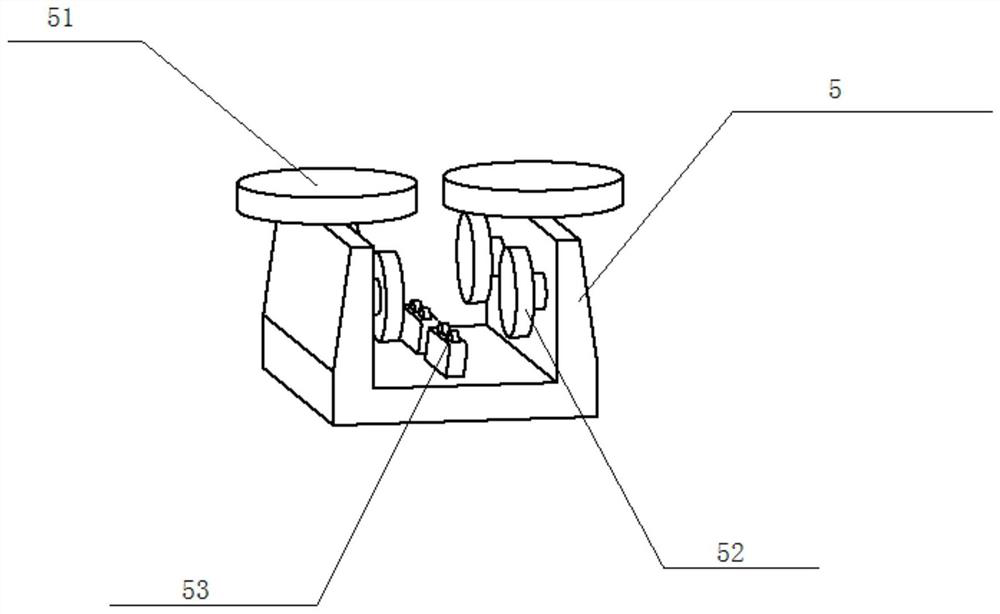

[0033] The track includes a closed-loop main track, a secondary track, a track fixing rod and a track fixing end, the track fixing end is located above the track, the top end of the track fixing rod is fixed to the bottom of the track fixing end, and part of the track fixing rod is The bottom of the main rail is connected to fix the main rail, and the bottom of part of the rail fixing rod is connected and fixed to the auxiliary rail. The auxiliary rails are distributed in the closed loop of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com