Tea cake pressing machine

A technology for pressing cakes and tea leaves, which can be used in presses, material forming presses, tea processing before extraction, etc., and can solve problems such as improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

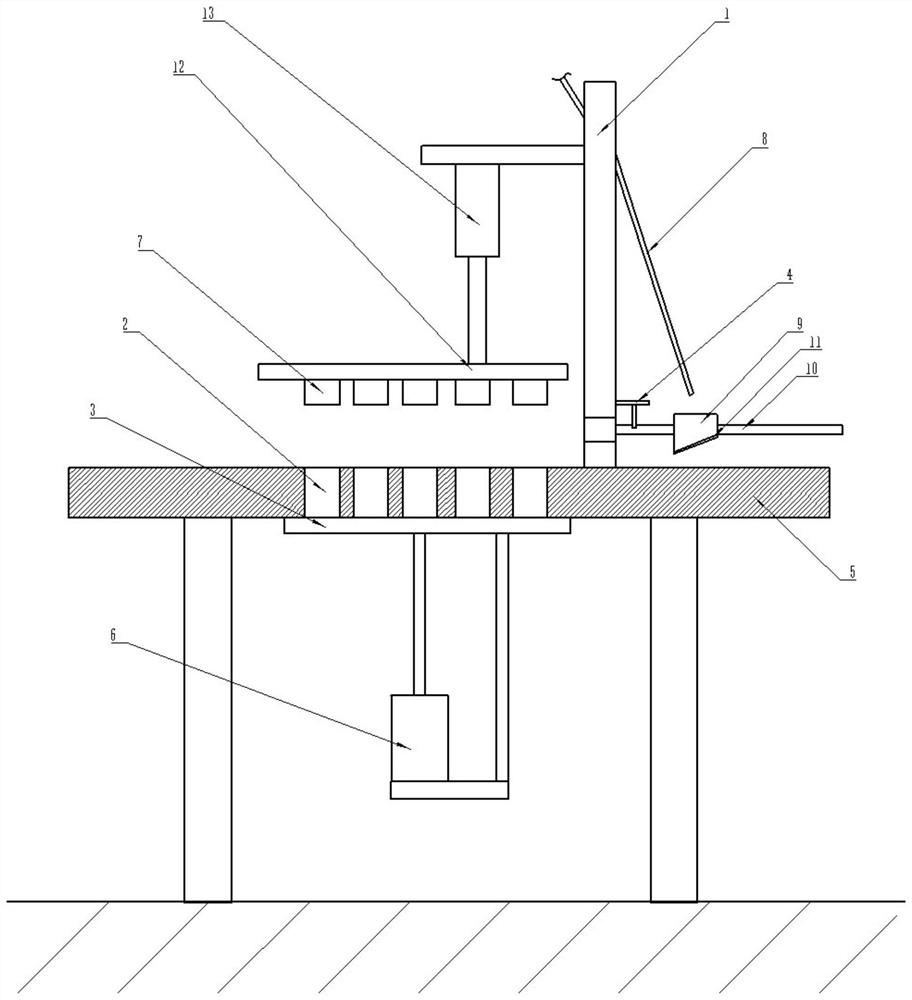

[0033] A tea cake press of the present embodiment includes:

[0034] A tea cake press (such as figure 1 shown), including:

[0035] Rack 1, a working platform 5 is fixed on the rack 1, and five tea cake through holes 2 for accommodating tea leaves are arranged on the working platform 5;

[0036] Pressing plate 3, the pressing plate 3 is located below the tea cake through hole 2 of the working platform 5, and the frame 1 is provided with a blanking drive component 6 for driving the pressing plate 3 to move up and down (in this embodiment, the blanking cylinder is selected. , which will be described in detail later);

[0037]Feeding mechanism, the feeding mechanism includes a blanking pipe 8 (sent from an existing feeder) and a distribution tray 9. The blanking pipe 8 and the frame 1 are fixedly connected by bolts, and between the distribution tray 9 and the frame 1 There is a limit slide rail 10, the limit slide rail 10 is clamped on both sides of the distribution plate 9 (e...

Embodiment 2

[0046] The difference between this embodiment and the first embodiment is that in this embodiment, a bacterial species inoculation part is also included, and the bacterial species inoculation part includes a liquid storage box, a liquid outlet pipe and an inoculation solenoid valve, and the liquid storage box is fixed on the limit slide rail 10 . One end of the liquid outlet pipe is connected to the liquid storage box, the other end of the liquid outlet pipe is bonded and fixed with the material distribution tray 9, and the liquid outlet pipe is a hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com