Air balance high-pressure rotary valve

A rotary valve and gas balance technology, applied in the field of rotary valves, can solve the problems of reduced sealing performance of rotary valves, damage to rotary valve components, etc., and achieve the effects of solving sealing failure, enhancing service life, and solving parts aging too quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

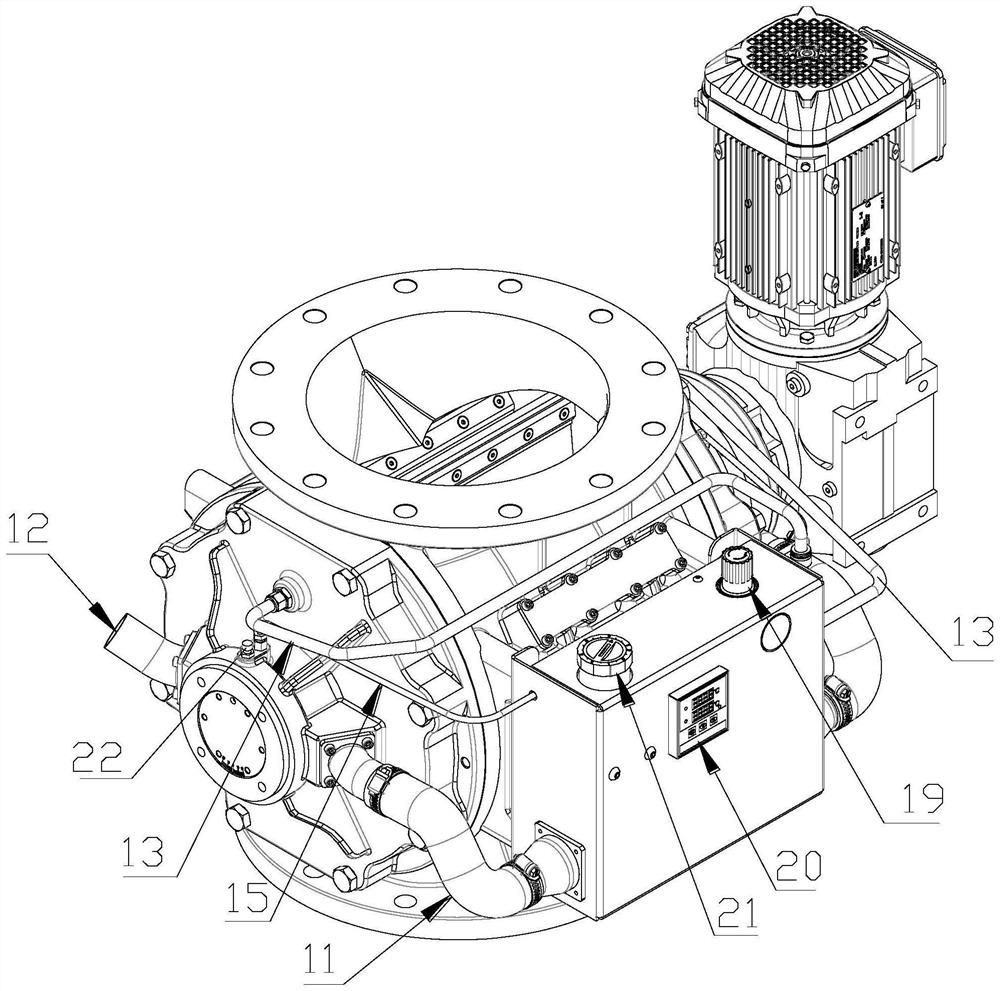

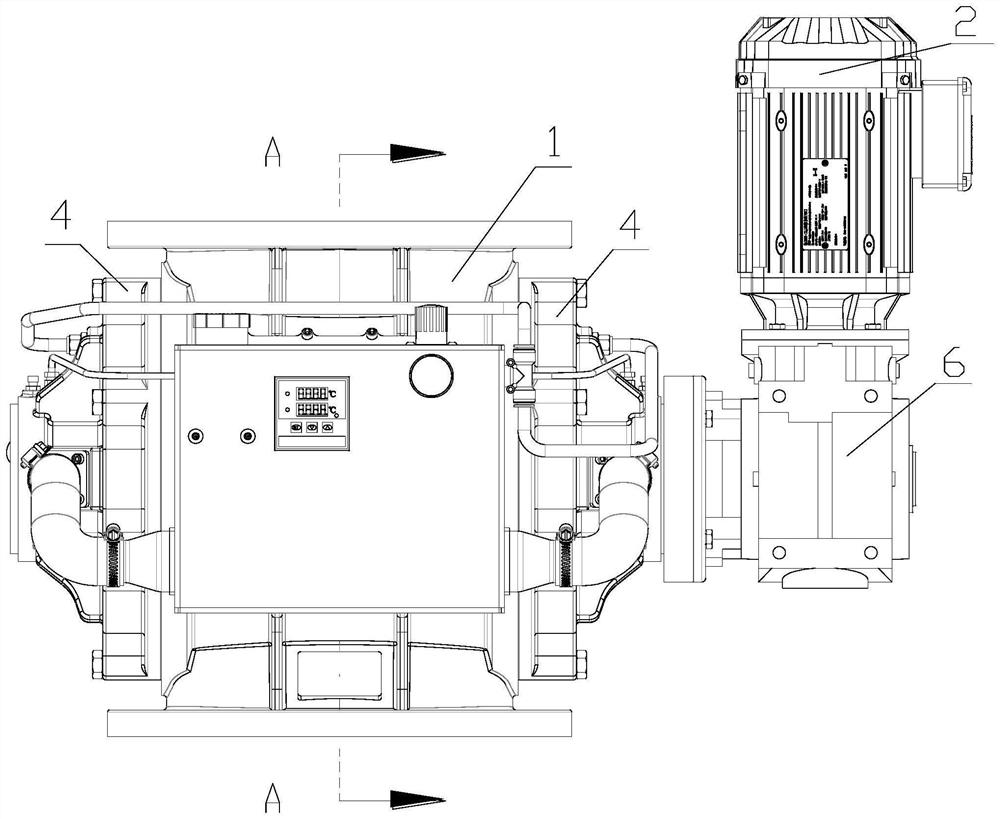

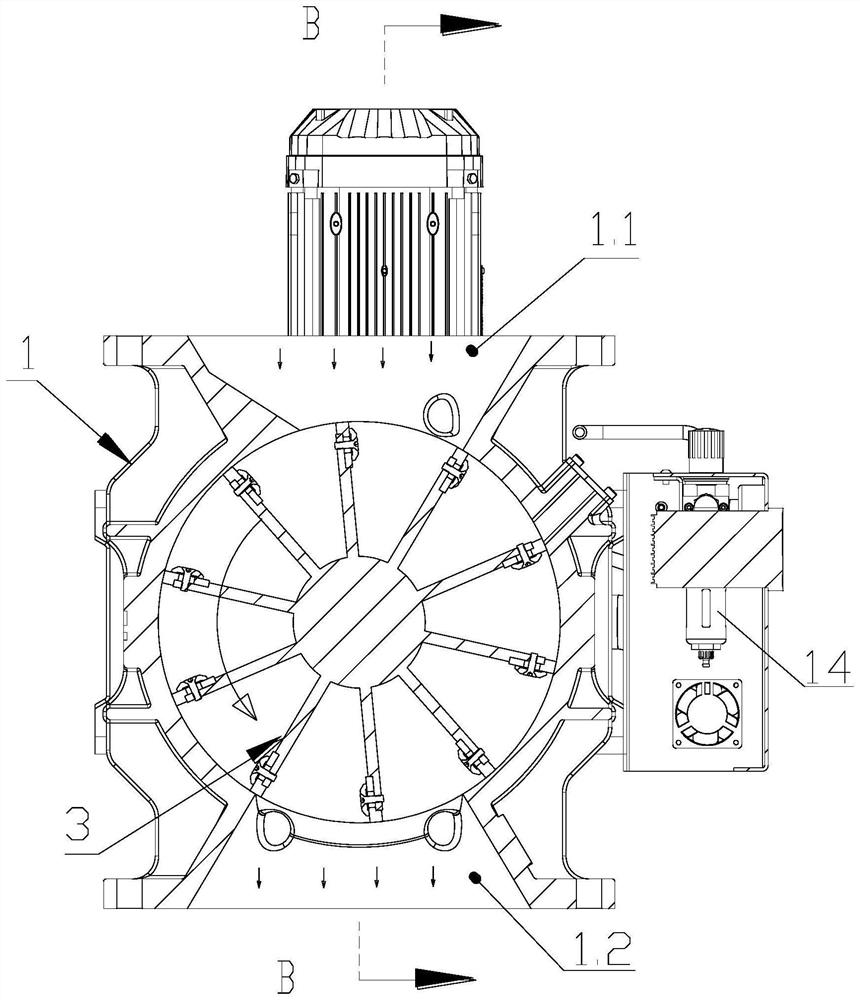

[0031] A kind of air balance high pressure rotary valve, see attached Figure 1 -Attached Figure 3 Shown, including housing 1, motor 2, rotor 3 and end cap 4, The upper and lower ends of the housing 1 have an inlet port 1.1 and an outlet port 1.2, the end cover 4 is fixed at the left and right ends of the housing 1, the end cover 4 is provided with a bearing 5, the rotor 3 is connected to the inner cavity of the housing 1 by the rotation of the bearing 5, the motor 2 is connected by the reducer 6 and the rotor 3 rotation, the same as the working process of the traditional rotary valve, the material enters the rotor from the inlet port of the housing 1.1, the motor 2 drives the rotor 3 to rotate, and the material is discharged from the outlet 1.2.

[0032] More specifically, in the present invention, see attached Figure 7 -Attached Figure 10As shown, the end cover 4 has a bearing housing chamber 4.1, a cooling air chamber 4.2, a sealing chamber 4.3 and a rotor containment chamber 4....

Embodiment 2

[0035] A kind of air balance high pressure rotary valve, see attached Figure 1 -Attached Figure 3 Shown, comprising housing 1, motor 2, rotor 3 and end cap 4, the upper and lower ends of the housing 1 having an inlet port 1.1 and an outlet port 1.2, the end cover 4 is fixed at the left and right ends of the housing 1, the end cover 4 is provided with a bearing 5, the rotor 3 is connected to the inner cavity of the housing 1 by the rotation of the bearing 5, the motor 2 is connected to the rotor 3 rotation by reducer 6.

[0036] The end cover 4 has a bearing housing chamber 4.1, a cooling air chamber 4.2, a sealing chamber 4.3 and a rotor holding chamber 4.4, the diameter of the cooling air chamber 4.2 is greater than the diameter of the bearing housing chamber 4.1, the bearing 5 sets are located in the bearing housing chamber 4.1, and then continue to refer to the attached Figure 7 -Attached Figure 10As shown, the inner wall of the cooling air chamber 4.2 is provided with an air i...

Embodiment 3

[0039] A kind of air balance high pressure rotary valve, see attached Figure 1 -Attached Figure 3 Shown, comprising housing 1, motor 2, rotor 3 and end cap 4, the upper and lower ends of the housing 1 having an inlet port 1.1 and an outlet port 1.2, the end cover 4 is fixed at the left and right ends of the housing 1, the end cover 4 is provided with a bearing 5, the rotor 3 is connected to the inner cavity of the housing 1 by the rotation of the bearing 5, the motor 2 is connected to the rotor 3 rotation by reducer 6.

[0040] The end cover 4 has a bearing housing chamber 4.1, a cooling air chamber 4.2, a sealing chamber 4.3 and a rotor holding chamber 4.4, the diameter of the cooling air chamber 4.2 is greater than the diameter of the bearing housing chamber 4.1, the bearing 5 sets are located in the bearing housing chamber 4.1, and then continue to refer to the attached Figure 7 -Attached Figure 10 As shown, the inner wall of the bearing housing chamber 4.1 is provided with an ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap