Adjustable hollow rotating platform

A rotary platform, adjustable technology, applied in machine/support, transmission, gear lubrication/cooling, etc., can solve the problems of noise, inapplicable gear ring, gear ring wear, etc., to reduce wear and damage, reduce wear and tear and noise, reducing the effect of excessive clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention;

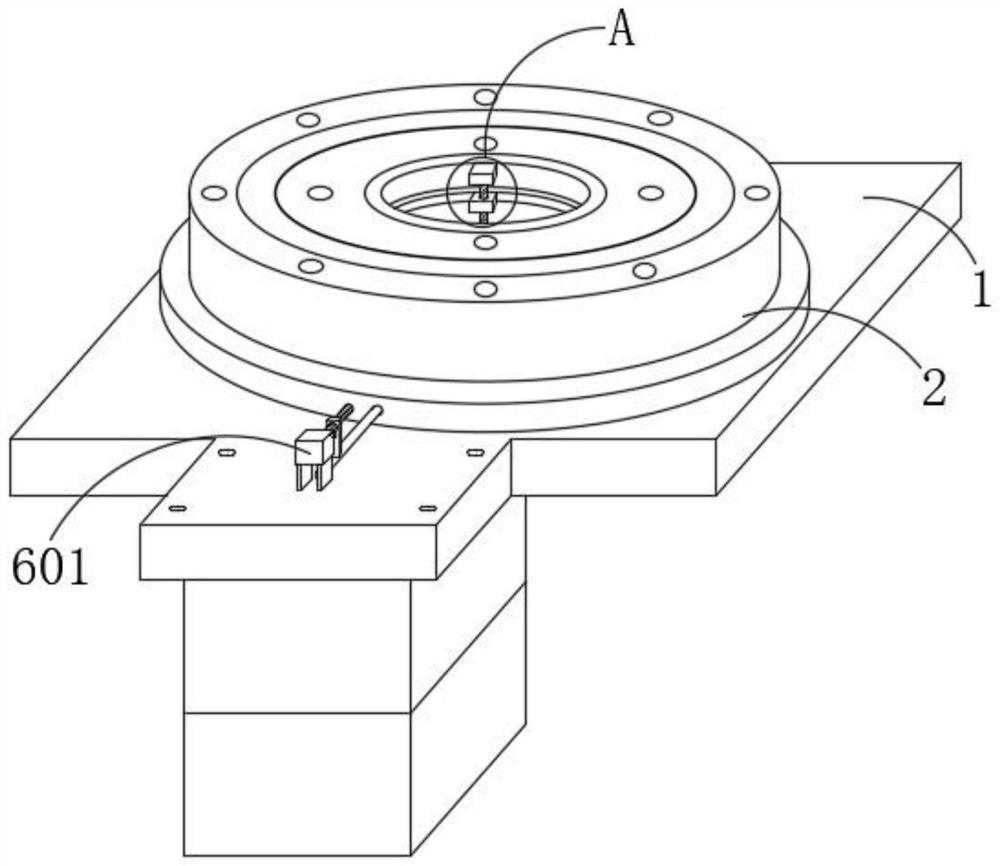

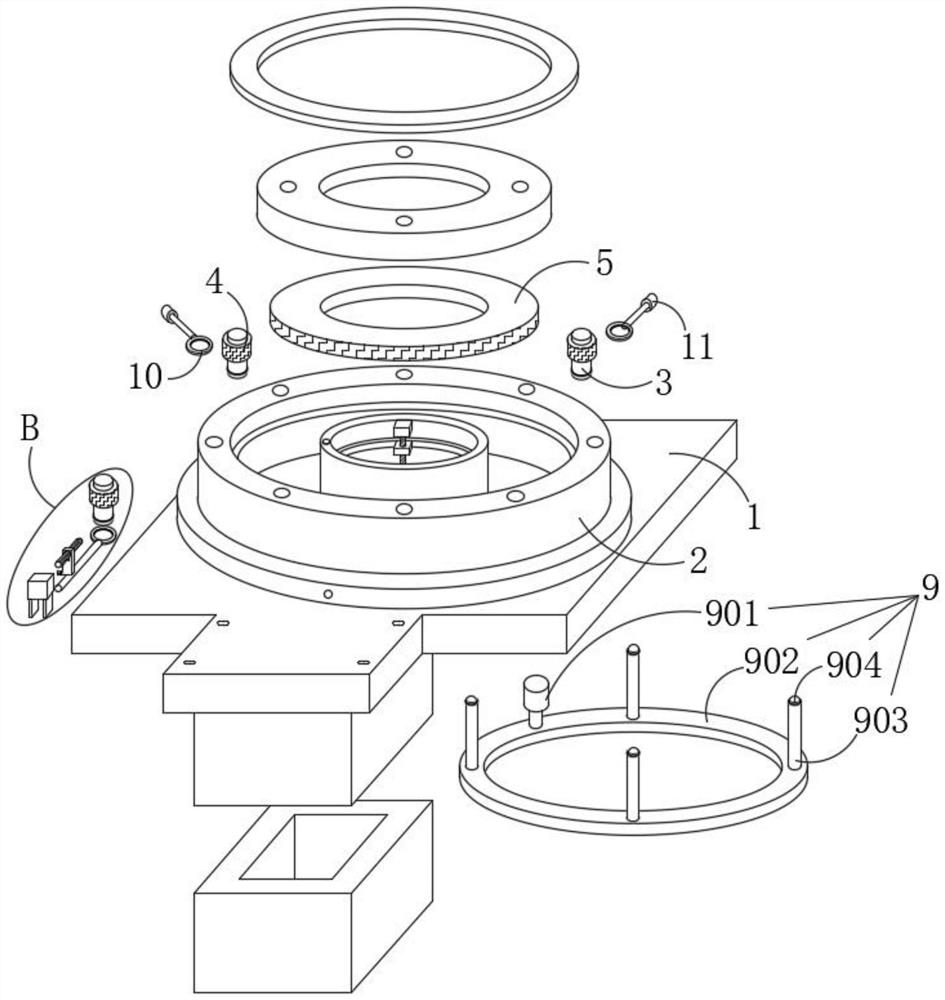

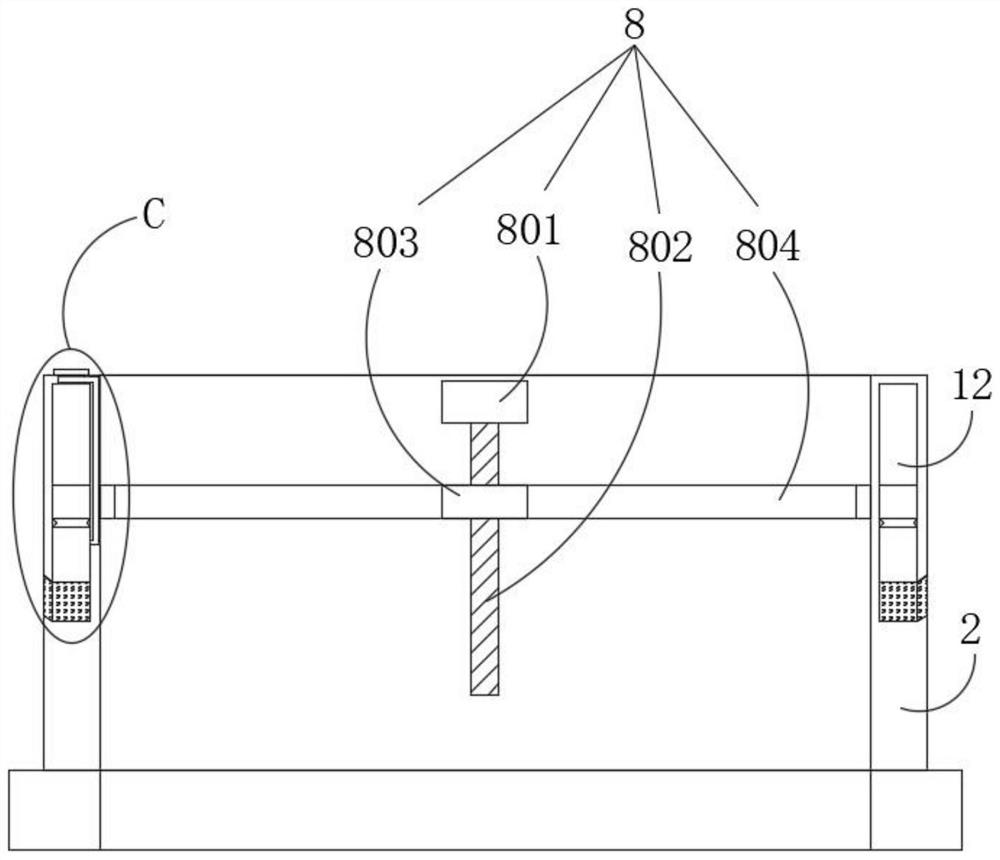

[0035] see Figures 1 to 6 In the present invention, an adjustable hollow rotating platform includes a bottom plate 1, a mounting seat 2 is installed on the top of the bottom plate 1, and a group of rotating shafts 3, a group of gears 4 and a gear ring 5 are respectively installed inside the mounting seat 2, The gear 4 is installed in the middle of the rotating shaft 3, the outer side of the gear 4 meshes with the outer side of the gear ring 5, the middle of the rotating shaft 3 is sleeved with a sleeve ring 10 that is rotatably connected with it, and the outer side of the front sleeve ring 10 is provided with an adjustment mechanism 6, A first electric push rod 11 is installed on the outer sides of the two collars 10 on the back. The first electric push rod 11 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com