Calibration method, device and system of rotary encoder

A technology of rotary encoder and calibration method, which is applied in the field of encoder, can solve the problems of increasing the cost of encoder calibration, increasing the difficulty of encoder calibration, and requiring high precision of calibration tools, and achieves simple and fast precision calibration, and the calibration process is simple and easy The effect of implementing and simplifying the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the current process of calibrating the rotary encoder, it is generally necessary to rotate the rotary encoder and the standard encoder by the same angle, and then compare and refer to the readings of the rotary encoder and the standard encoder, so as to determine the value of the rotary encoder. reading error. However, this calibration method often requires high synchronization accuracy of the rotation of the code discs of the rotary encoder and the standard encoder. Otherwise, the rotation angle error between the standard encoder and the rotary encoder will directly affect the calibration accuracy of the rotary encoder.

[0040] In practical applications, it is relatively difficult to achieve high-precision synchronization between the standard encoder and the rotary encoder, which further causes the problem of high difficulty in calibrating the rotary encoder.

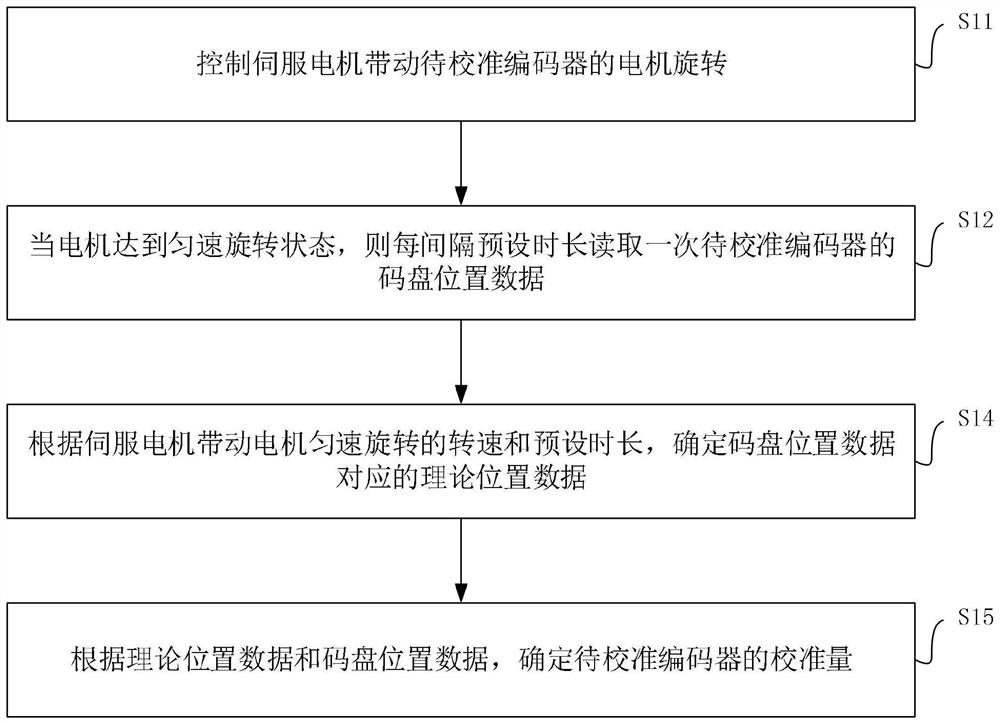

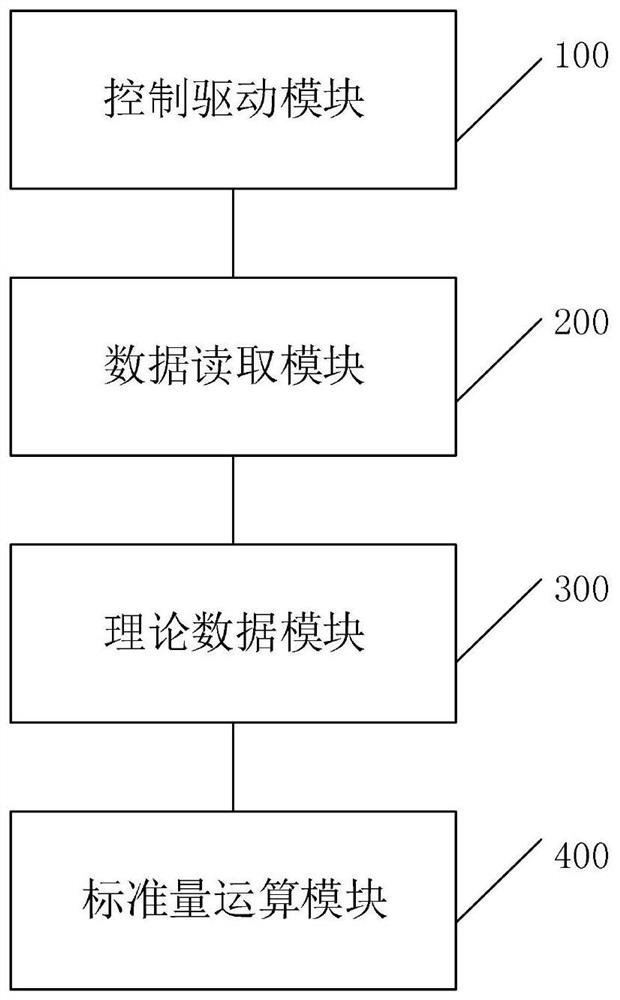

[0041] Therefore, the present application provides a technical solution that can reduce the calibration d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com