Method and device for testing strength and plasticity of titanium alloy welding strip

A test method and test device technology, which are applied in the direction of measurement device, strength characteristics, and material strength by applying stable tension/pressure, can solve the problems of inability to measure the strength and plasticity index of titanium alloy welding strips, and achieve simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict, and the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

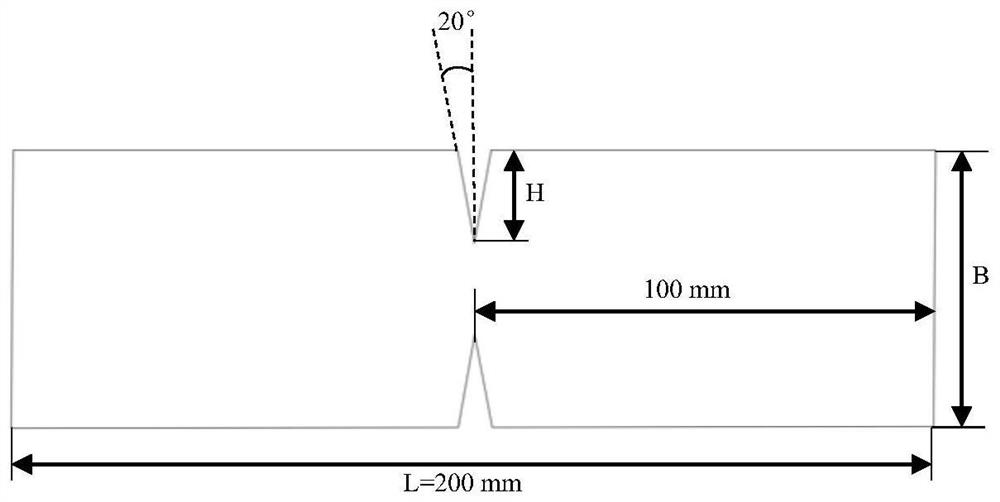

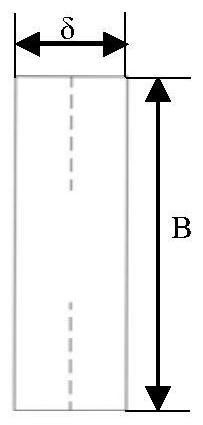

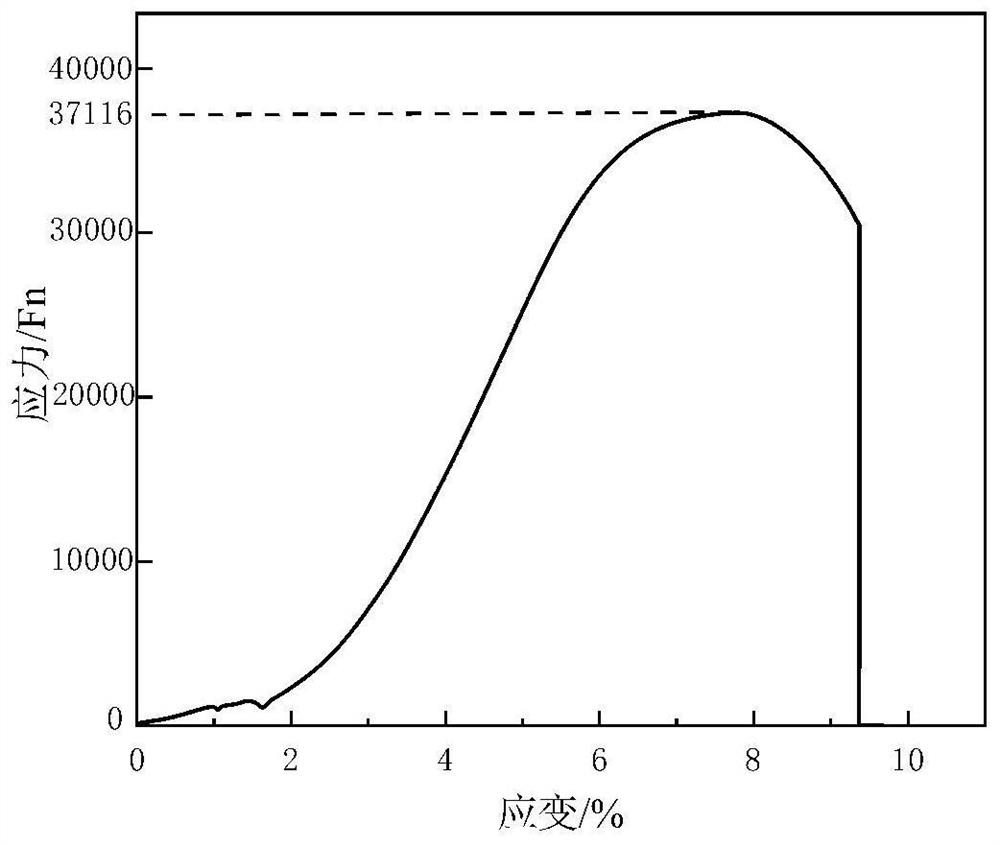

[0041] see Figure 1-6 Describe this embodiment, a method for testing the strength and plasticity of a titanium alloy welding strip, which comprises the following steps:

[0042] Step 1: Cut a certain length of titanium alloy welding strip, you can take any method to cut it, but it should be ensured that during the cutting process, the titanium strip does not have any deformation, and both ends of the titanium alloy should be flat and neat, in the center of the length direction of the welding strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap