Full-automatic robot coffee making device

A technology for manufacturing devices and robots, applied in beverage preparation devices, manipulators, manufacturing tools, etc., can solve problems such as poor control of material volume, food safety, and cumbersome steps, so as to improve the level of material management, solve the shortage of personnel, and improve The effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

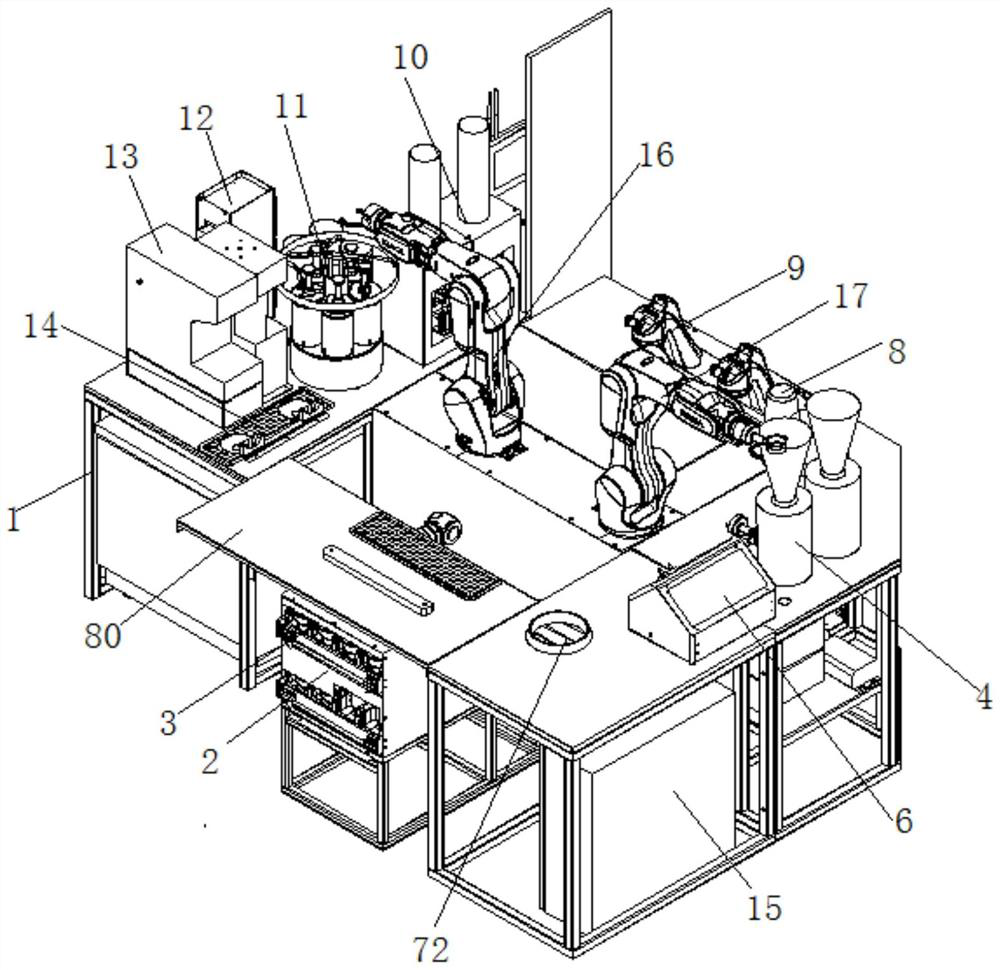

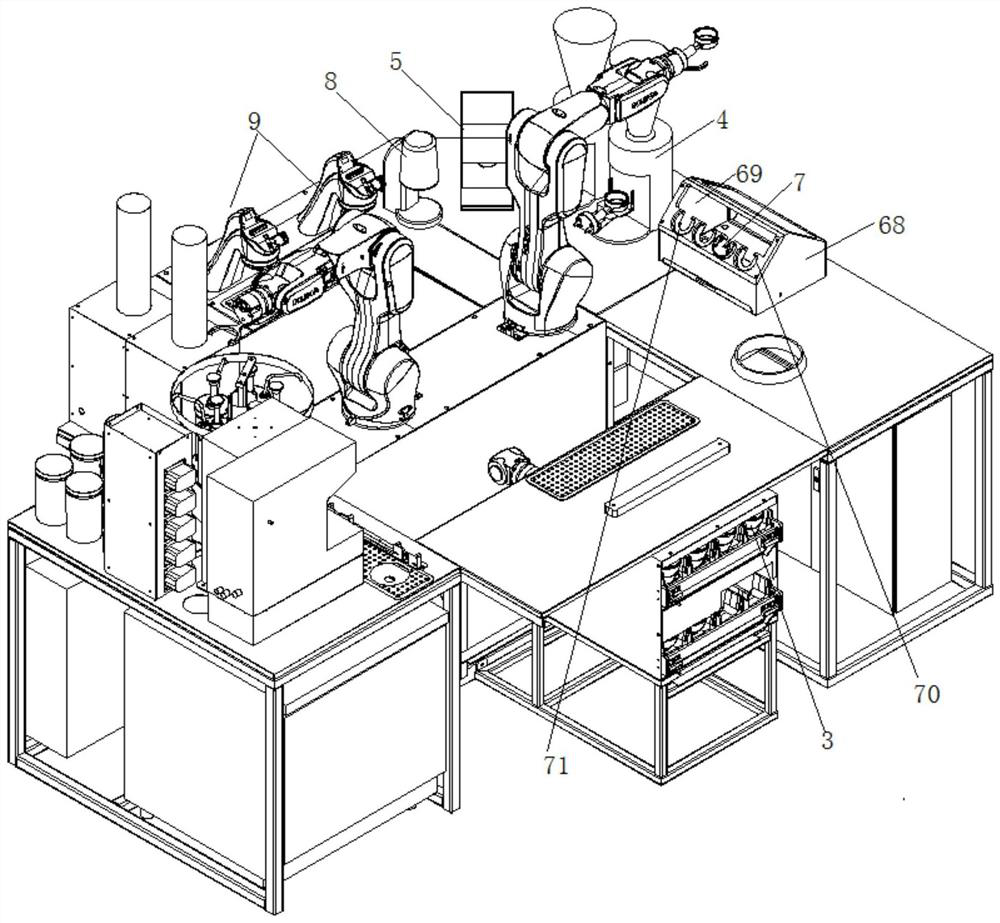

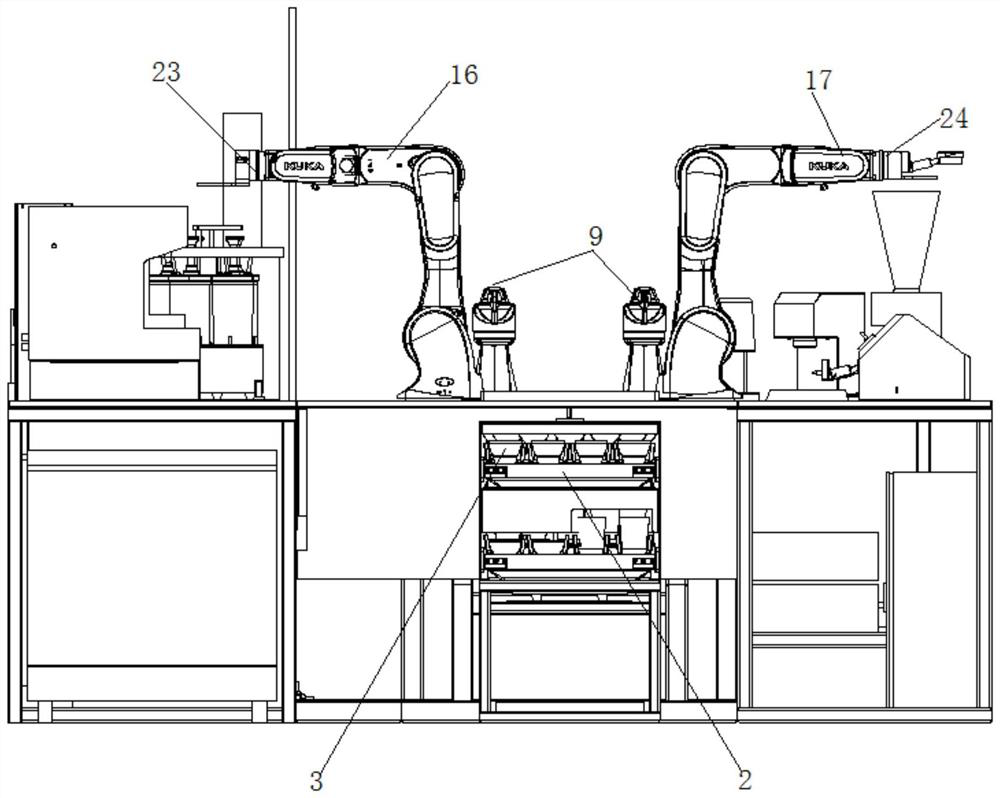

[0027] Such as Figure 1-Figure 3 A fully automatic robot coffee making device shown includes a mounting bracket 1, a meal taking plate 80 is installed on the front side of the mounting bracket 1, and a dine-in cup supply machine 2 is installed below the meal picking plate 80, so A coffee milk can gripper 3 is placed on the cup supply machine 2, a mechanical arm is installed in the middle of the installation bracket 1, and a mill 4 is installed on the right side of the mechanical arm. A powder distributor 5 is installed on one side, and a powder scoop incubator 6 is installed on the other side. A powder scoop handle 7 is placed inside the powder scoop incubator 6, and an automatic cleaning machine is installed on one side of the powder scoop incubator 6. A powder device 72, a powder compactor 8 is installed on one side of the powder distributor 5, a coffee machine 9 is installed on one side of the powder compactor 8, an automatic cup dropping machine 10 is installed on one sid...

Embodiment 2

[0029] On the basis of Embodiment 1, two mechanical arm structures can be selected, and the mechanical arm structure is not limited to a single structural form, and a lifting structure 81 can be used, such as Figure 11 As shown, the hoisting structure 81 is fixed above the installation bracket 1 through the hoisting bracket 82, and can absorb and hoist the handle 3 of the coffee milk tank and the handle 7 of the powder scoop.

Embodiment 3

[0031] Such as Figure 1-Figure 10 A fully automatic robot coffee making device shown includes a mounting bracket 1, a meal taking plate 80 is installed on the front side of the mounting bracket 1, and a dine-in cup supply machine 2 is installed below the meal picking plate 80, so A coffee milk can gripper 3 is placed on the cup supply machine 2, a mechanical arm is installed in the middle of the installation bracket 1, and a mill 4 is installed on the right side of the mechanical arm. A powder distributor 5 is installed on one side, and a powder scoop incubator 6 is installed on the other side. A powder scoop handle 7 is placed inside the powder scoop incubator 6, and an automatic cleaning machine is installed on one side of the powder scoop incubator 6. A powder device 72, a powder compactor 8 is installed on one side of the powder distributor 5, a coffee machine 9 is installed on one side of the powder compactor 8, an automatic cup dropping machine 10 is installed on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com