Magnetic separator for magnetic separation of household appliance parts and household appliance recovery device with magnetic separator

A technology for magnetic separators and household appliances, which is applied in the direction of electronic waste recycling, recycling technology, magnetic separation, etc., and can solve problems such as high requirements, low material efficiency of magnetic separators, increased production costs of magnetic separators, customer use costs, etc., to achieve Improve the effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

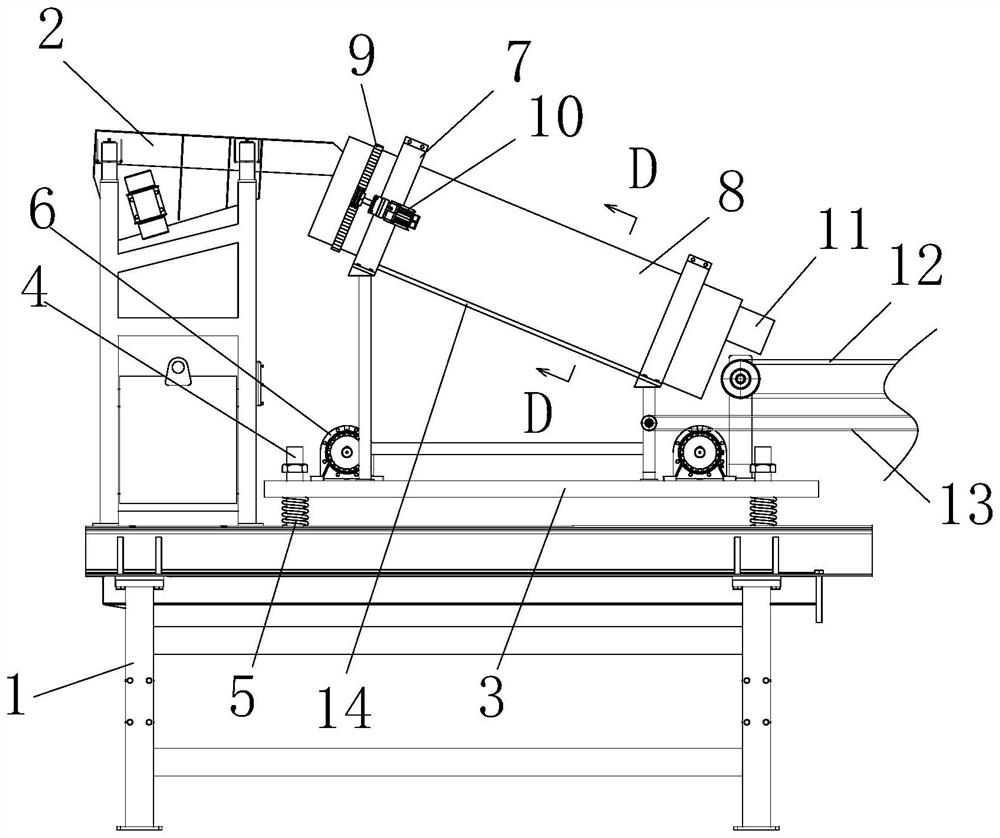

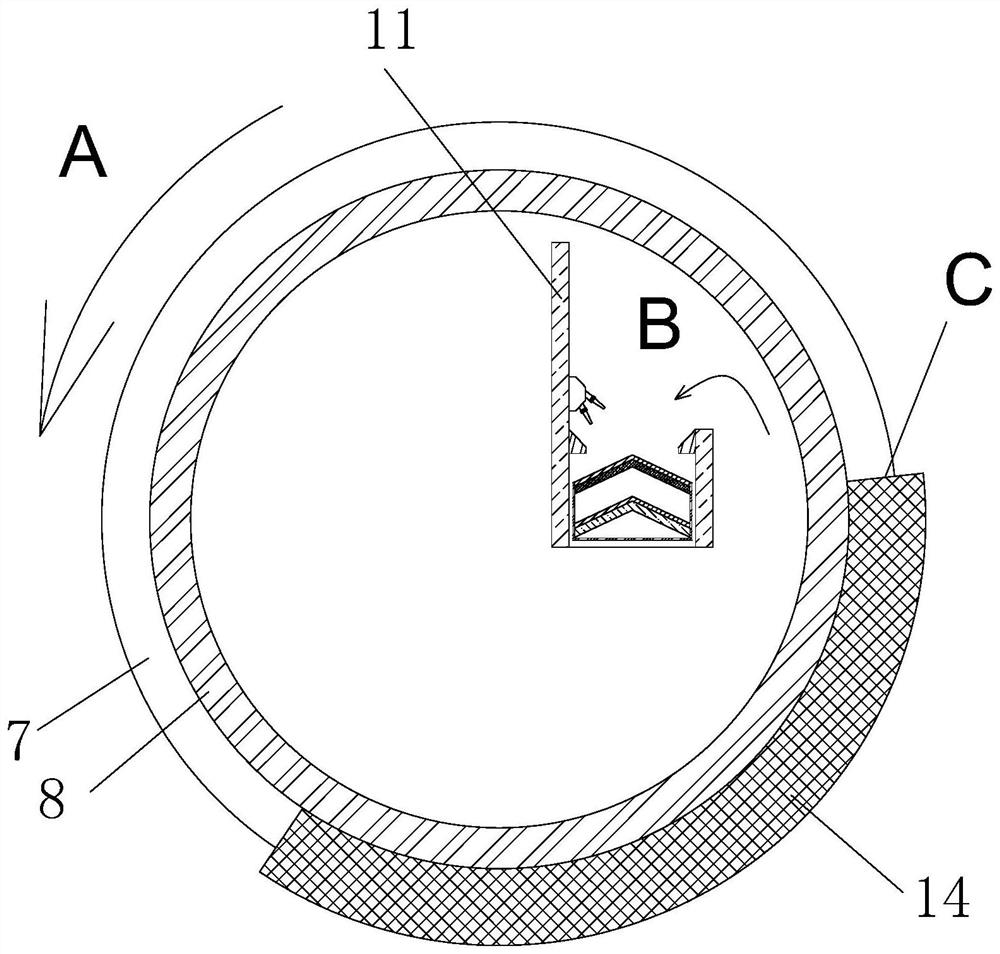

[0025] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

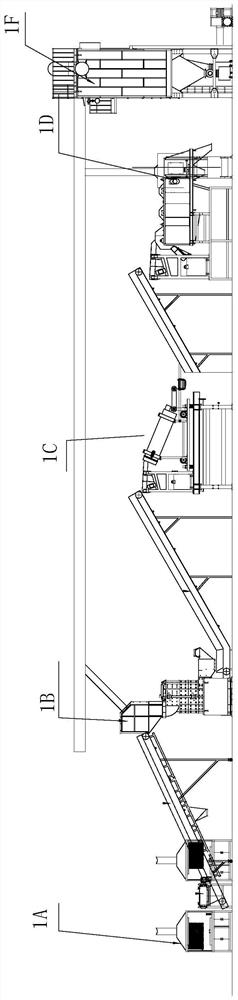

[0026] refer to Figures 1 to 4 The embodiment of the present invention discloses a home appliance recycling device having a magnetic separator for magnetic separation of household appliance parts, including a manual dismantling table 1A, a vertical crusher 1B, and a magnetic separator for magnetic separation of household appliance parts. 1C, Eddy current sorting machine 1D.

[0027] First, on the manual dismantling table 1A, the home appliance is initially dismantled by the operator, and then some disassembled parts are transported to the vertical crusher 1B by the conveyor for crushing, and the crushed parts are transported to the magnetic crusher 1B for crushing. The magnetic separator 1C for selecting home appliance parts magnetically selects the parts that can be magnetically attracted, and the parts that can be magnetically attracted are rec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap