Nut burr removing machine and discharging mechanism thereof

A blanking and nut technology, which is applied in the field of nut processing, can solve problems such as loosening, unusable nuts, and affecting the normal use of nuts, and achieve the effect of increasing the rate of blanking, accelerating the reciprocating frequency, and improving the efficiency of blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

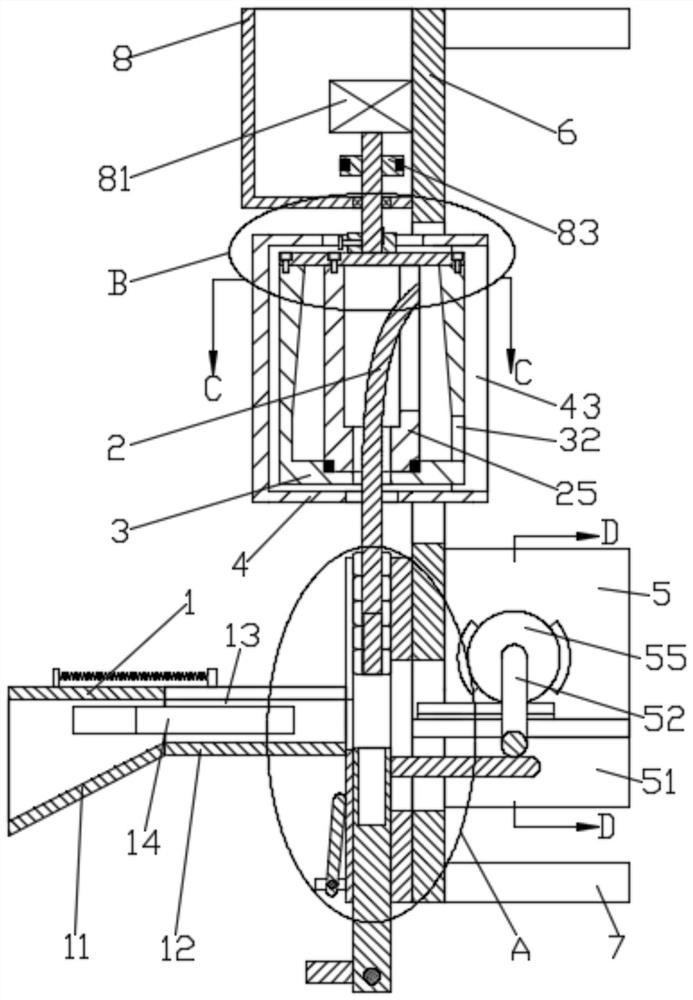

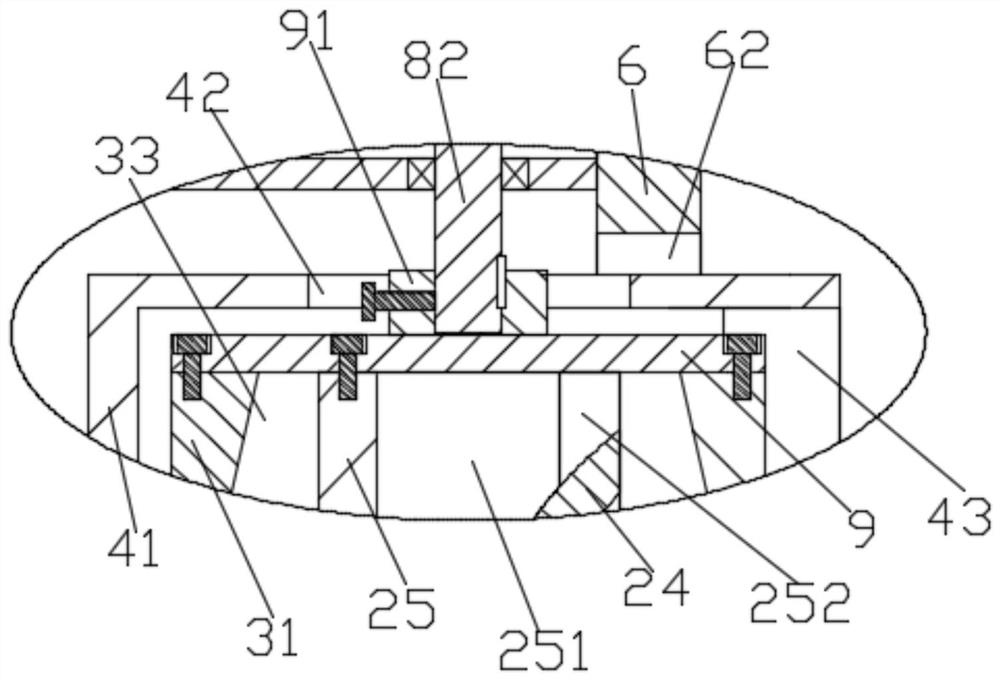

[0030] Such as figure 1 A nut deburring machine and its blanking mechanism shown include a bottom plate 6 on which a blanking mechanism 1, two mutually symmetrical deburring mechanisms 2, two mutually symmetrical oscillation mechanisms 4 and Two mutually symmetrical protective shells 4 also include a first power mechanism 8 and a second power mechanism 5, the first power mechanism 8 provides power for the deburring mechanism 2 and the vibration mechanism 4, the The second power mechanism 5 ensures that the unloading mechanism 1 and the deburring mechanism 2 operate smoothly, and the other end of the bottom plate 6 is fixedly provided with a plurality of legs 7 .

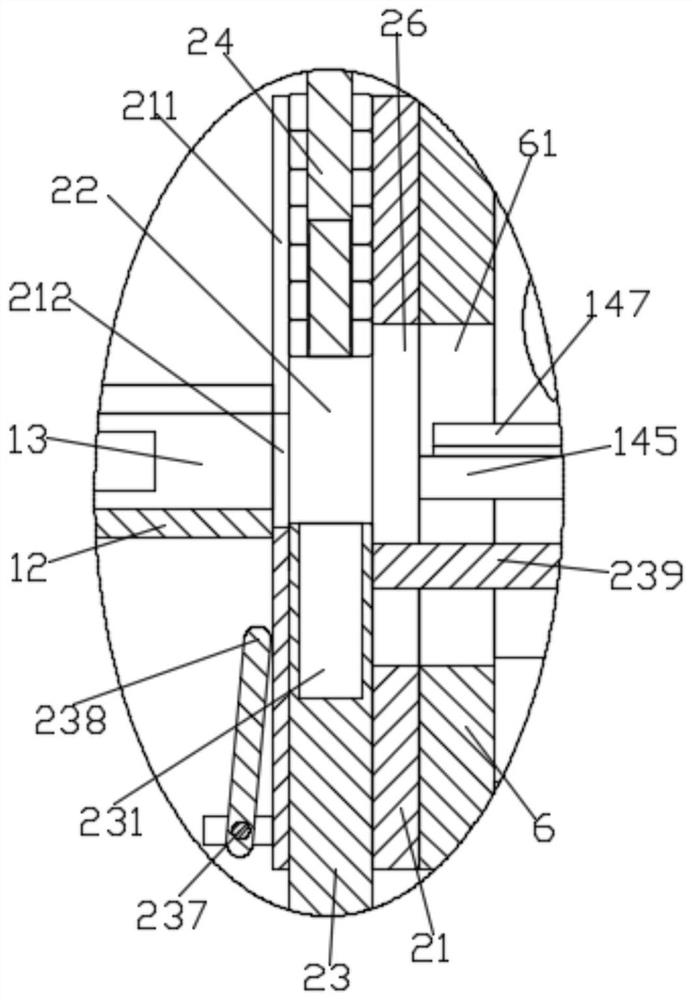

[0031] Such as figure 1 , figure 2 and Figure 7 As shown, the blanking mechanism 1 includes a hopper 11 and a finishing plate 14, two blanking parts 12 protrude on the hopper 11, and the blanking part 12 is provided with a blanking hole 13, and the blanking part 12 is provided with a blanking hole 13. The hole ...

Embodiment 2

[0050] Embodiment 2: as Figure 8 and Figure 9 As shown: the second power mechanism includes a first cylinder 98 and a second cylinder 99, the first cylinder 98 is fixed on the positioning plate, and the extension end of the first cylinder 98 is fixed between the push rod 23 Connecting plate 97 is connected, and described first cylinder 98 drives described ejector rod 23 to realize reciprocating motion through connecting plate 97, and described second cylinder 99 is fixed on described base plate 6, and the extension end of described second cylinder 99 is connected with The finishing board 14 is fixedly connected, and the finishing board 14 is driven to reciprocate by the second cylinder 99 .

[0051] Processing steps:

[0052] Step 1: When unloading, the first cylinder 99 drives the finishing plate 14 to do reciprocating motion and starts discharging, the finishing plate 14 continuously presses the nuts in the hopper 11, so that the nuts fall in an orderly manner The nuts ...

Embodiment 3

[0058] A rotating shaft is provided for rotation and cooperation between the mounting plates 51, and the rotating shaft is power-cooperated with the second motor 54. A cam is fixed on the rotating shaft, and the rotating cam drives the moving plate 239 to move. The rotating shaft A missing-toothed gear 55 is provided on the top, and the limiting rack 147 is driven to move by the missing-toothed gear 55 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com