Fracture-resistant connecting structure of wind wheel blade and variable-pitch bearing

A technology of variable pitch bearings and wind rotor blades, which is applied in the control of wind turbines, the assembly of wind turbines, and wind power generation. It can solve problems such as fatigue fractures, reduce stress concentration, improve fracture resistance, and increase connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

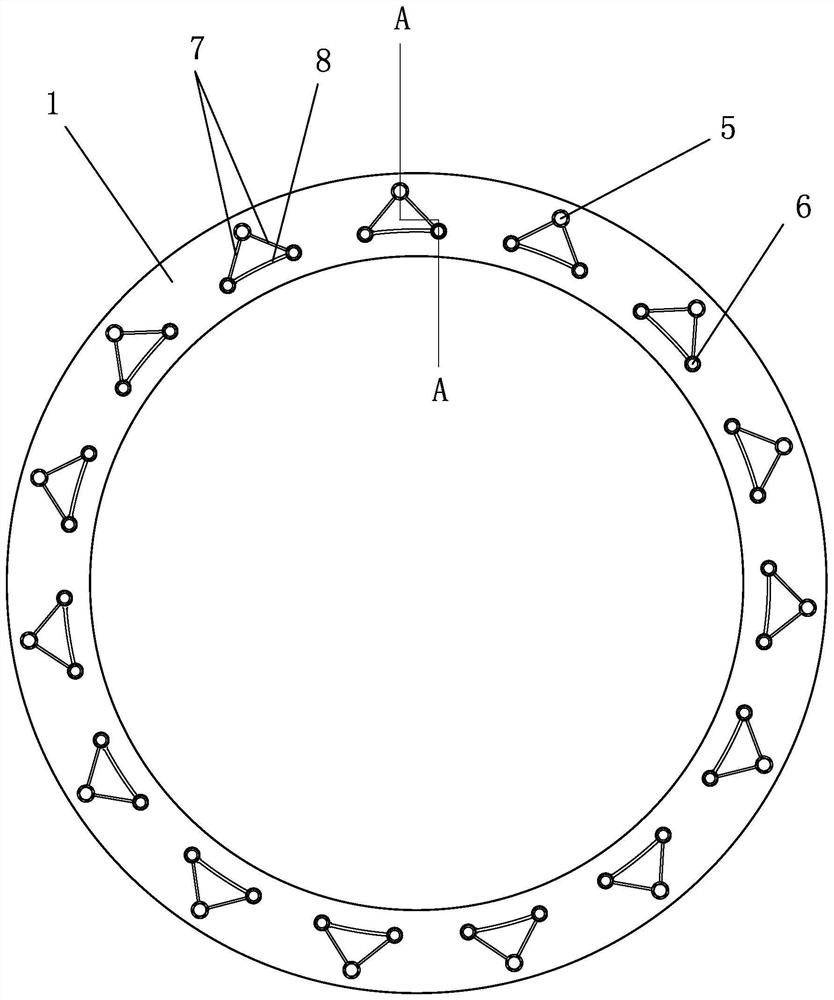

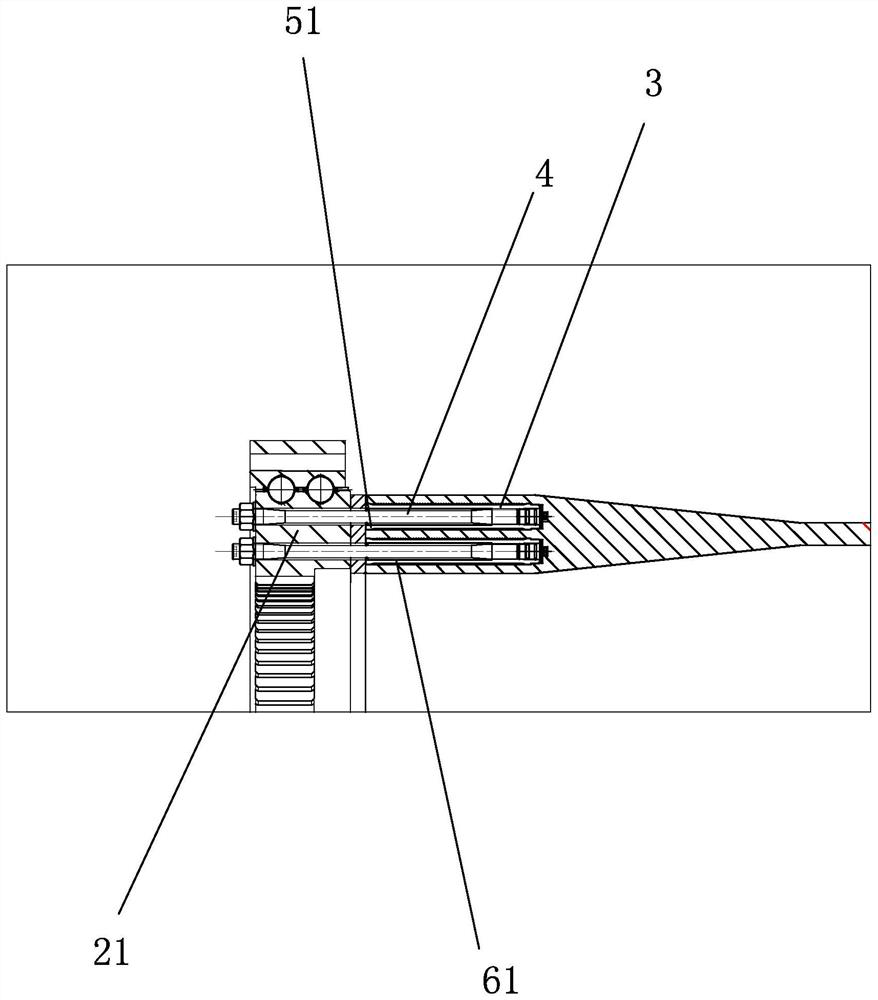

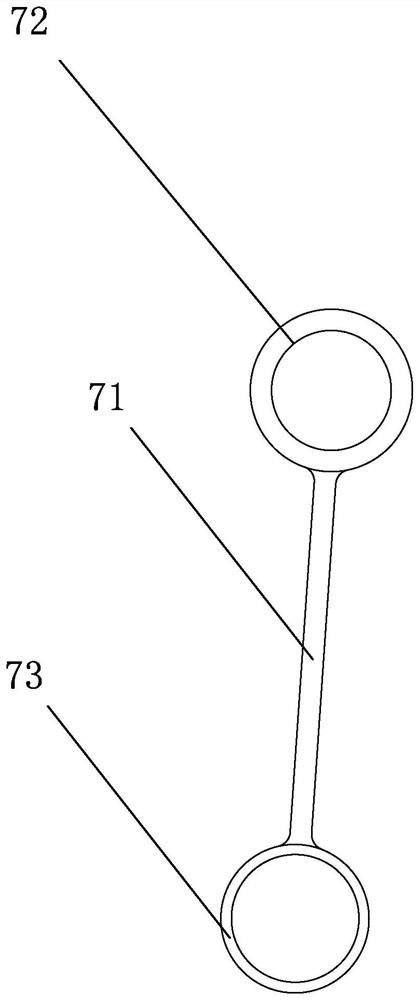

[0024] Such as figure 1 , 2 As shown, a fracture-resistant connection structure between a wind turbine blade and a pitch bearing includes a blade 1 and a pitch bearing 2, and the root of the blade 1 is connected to the inner ring 21 of the pitch bearing 2 through a fixing member 4. It is characterized in that, The root of the blade 1 is radially provided with at least two sets of fixing holes, each of which is provided with a pre-embedded positioning sleeve 3, and the inner ring 21 of the pitch bearing is provided with through holes corresponding to the set of fixing holes. 4 Go through the via hole and connect the pre-embedded positioning sleeve 3. The fixing hole group includes a first fixing hole group 5 close to the outer contour of the blade 1 and a second fixing hole group 6 near the inner cavity of the blade 1, the first fixing hole group 5 includes an outer ring fixing hole 51, and the first fixing hole group 5 includes an outer ring fixing hole 51. The second fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com