Pancake pressing device for pancake baking machine and pancake baking processing mechanism

A pancake machine and pancake technology, applied in the field of pancake machines, can solve the problems of heat loss, ineffective use of energy, inability to separate, etc., to achieve the effect of avoiding pollution and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

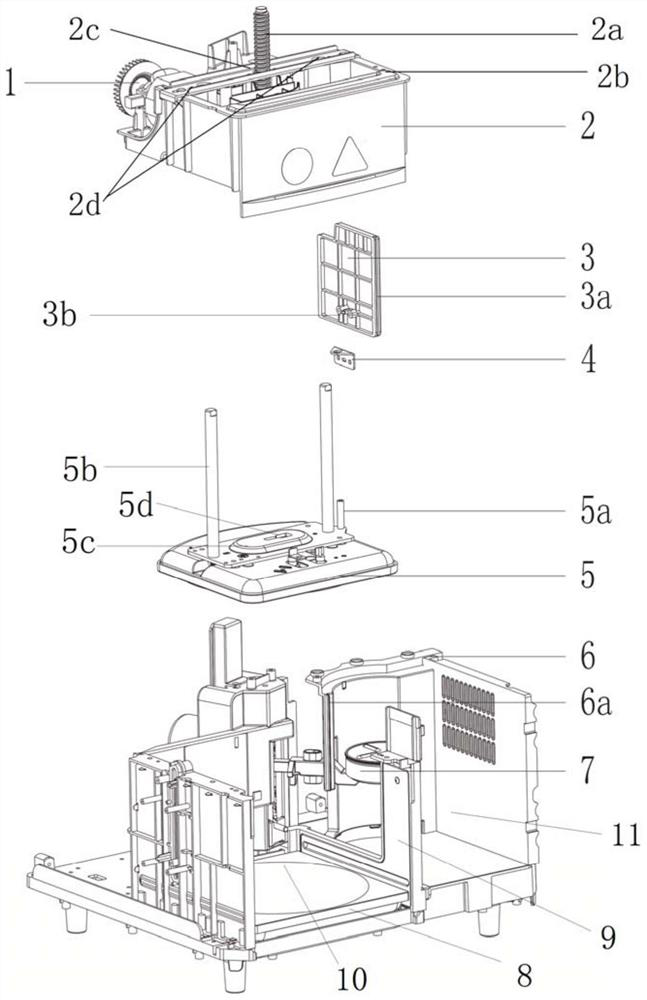

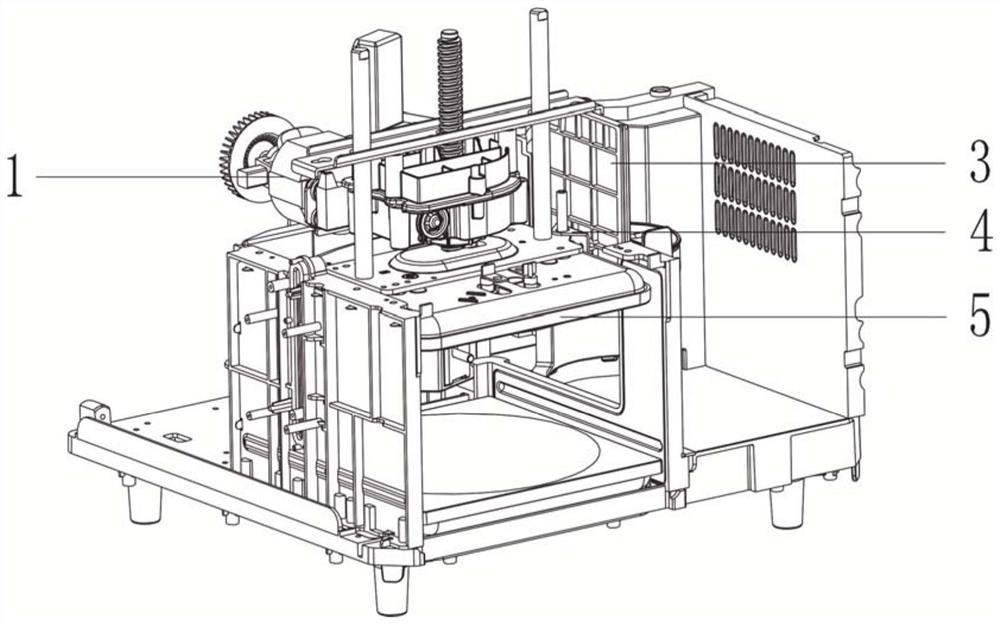

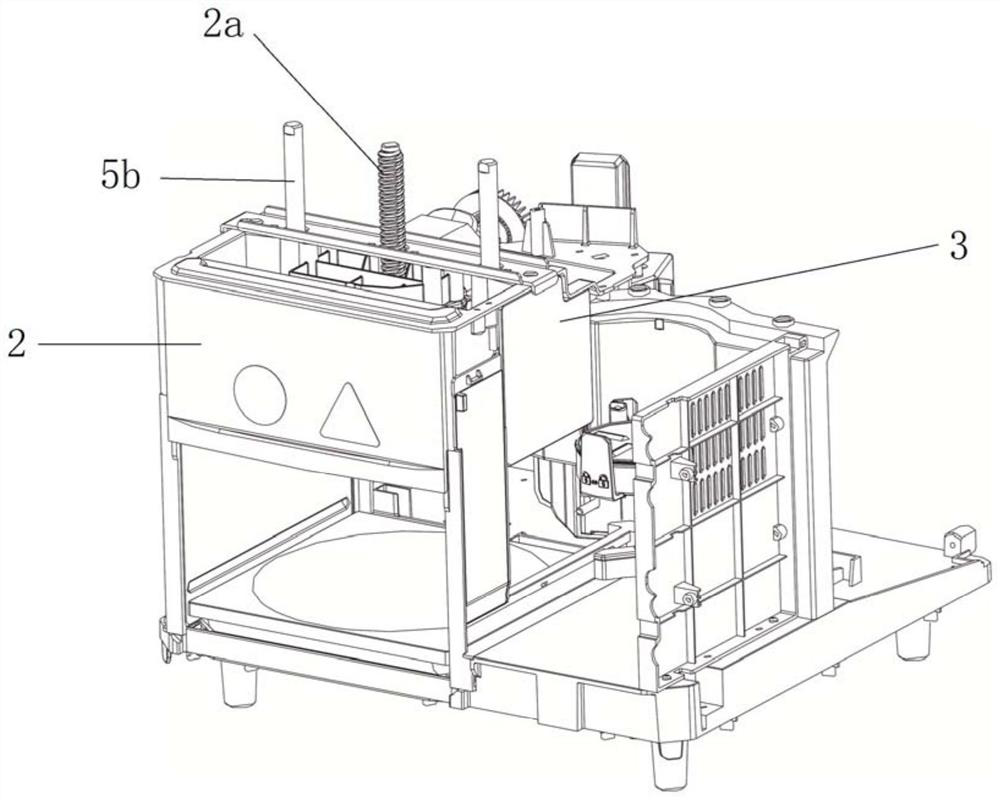

[0039] See figure 1 and figure 2 . figure 1 A schematic diagram of the exploded structure of the pancake processing mechanism with the cake pressing device of the present application is shown, figure 2 A schematic diagram of the assembly structure of the pancake processing mechanism with a cake pressing device according to the present application is shown.

[0040] The pancake processing mechanism includes: a bracket 6 , an upper frame 2 installed and fixed on the upper part of the bracket 6 , a cake pressing device installed on the bracket 6 , and a drive device 1 installed on the upper frame 2 .

[0041] As shown, the rack 6 has a first chamber 10 for pressing and / or baking operations and a second chamber 11 for preparing the dough, wherein the first chamber 10 and the second chamber are A notched partition wall 9 is interposed between the chambers 11 .

[0042] The bottom of the first chamber 10 is provided with a lower baking tray 8 .

[0043] The second chamber 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com