Yunnan big-leaf yellow tea and preparation method thereof

A technology of Yunnan big leaf and production method, which is applied to tea treatment before extraction, climate change adaptation and other directions, can solve the problems of poor tea soup and taste, affecting the quality of yellow tea, excessive yellowing, etc., so as to reduce the time and taste of yellowing. The effect of fresh and refreshing glycol and bright yellow soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

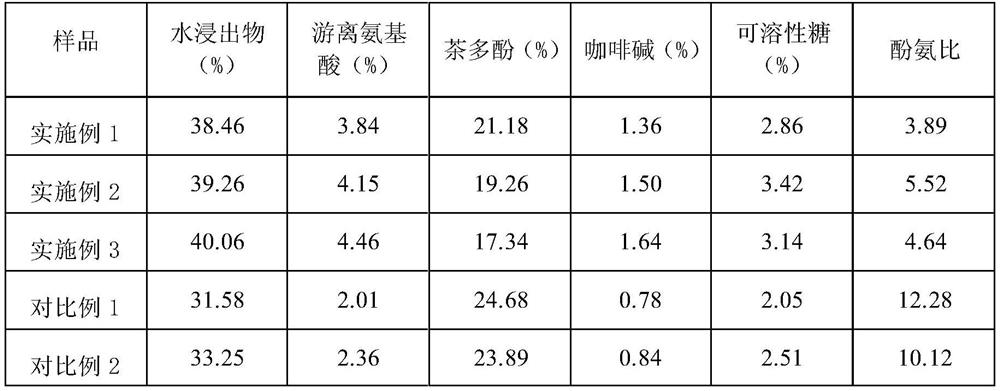

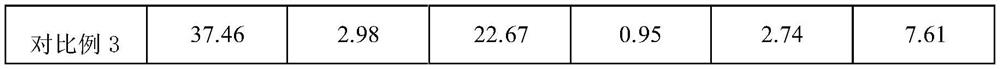

Examples

Embodiment 1

[0026] A preparation method of Yunnan large-leaf yellow tea, comprising the following steps:

[0027] S1. Picking and laying of fresh leaves: Pick the fresh leaves of one bud and four leaves, one bud and five leaves of Yunnan big-leaf tea tree, and place the fresh leaves in the withering tank of the withering machine at a temperature of 18°C and a humidity of 60%. Spread out under the conditions of 3 hours, and the thickness of the spread leaf is 3cm;

[0028] S2. Fixing: Put the spread tea leaves in a fixing pot for fixing, and control the temperature of the fixing pot to be 220°C. During the fixing process, the tea leaves are suffocated and combined until the leaves are soft and dark green in color. The whole process of finishing lasted 7min;

[0029] S3. Preliminary yellowing: soak the towel until it does not drip water to obtain a wet towel; pile the tea leaves after the greening into a metal utensil, then cover the wet towel on the top of the metal utensil, place it in...

Embodiment 2

[0037] A preparation method of Yunnan large-leaf yellow tea, comprising the following steps:

[0038] S1. Picking and laying of fresh leaves: Pick the fresh leaves of one bud and four leaves, one bud and five leaves of Yunnan big-leaf tea tree, and place the fresh leaves in the withering tank of the withering machine at a temperature of 30°C and a humidity of 80%. Spread out under the conditions of 4h, the thickness of the spread leaf is 5cm;

[0039] S2. Fixing: Put the spread tea leaves in a fixing pot for fixing, and control the temperature of the fixing pot to be 240°C. During the fixing process, the tea leaves are suffocated and combined until the leaves are soft and dark green in color. The whole process of finishing lasted 7min;

[0040] S3. Preliminary yellowing: soak the towel until it does not drip water to obtain a wet towel; pile the tea leaves after the greening into a metal utensil, then cover the wet towel on the top of the metal utensil, place it in a Titian m...

Embodiment 3

[0048] A preparation method of Yunnan large-leaf yellow tea, comprising the following steps:

[0049] S1. Picking and laying of fresh leaves: Pick the fresh leaves of one bud and four leaves, one bud and five leaves of Yunnan big-leaf tea tree, and place the fresh leaves in the withering tank of the withering machine at a temperature of 24°C and a humidity of 70%. Lay out under the conditions of 3.5h, and the thickness of the spread leaf is 4cm;

[0050] S2. Fixing: Put the spread tea leaves in a fixing pot for fixing, and control the temperature of the fixing pot to be 230°C. During the fixing process, the tea leaves are suffocated and combined until the leaves are soft and dark green in color. The whole process of finishing lasted 7min;

[0051] S3. Preliminary yellowing: soak the towel until it does not drip water to obtain a wet towel; pile the tea leaves after the greening into a metal utensil, then cover the wet towel on the top of the metal utensil, place it in a Titia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com