Pole piece extension consistency control method and control system

A technology of control system and control method, which is applied in the direction of electrode manufacturing, rolling mill control device, electrode rolling/calendering, etc., can solve the problems of inability to ensure the consistency of pole piece extension and inability to realize online foil extension measurement, so as to ensure the extension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

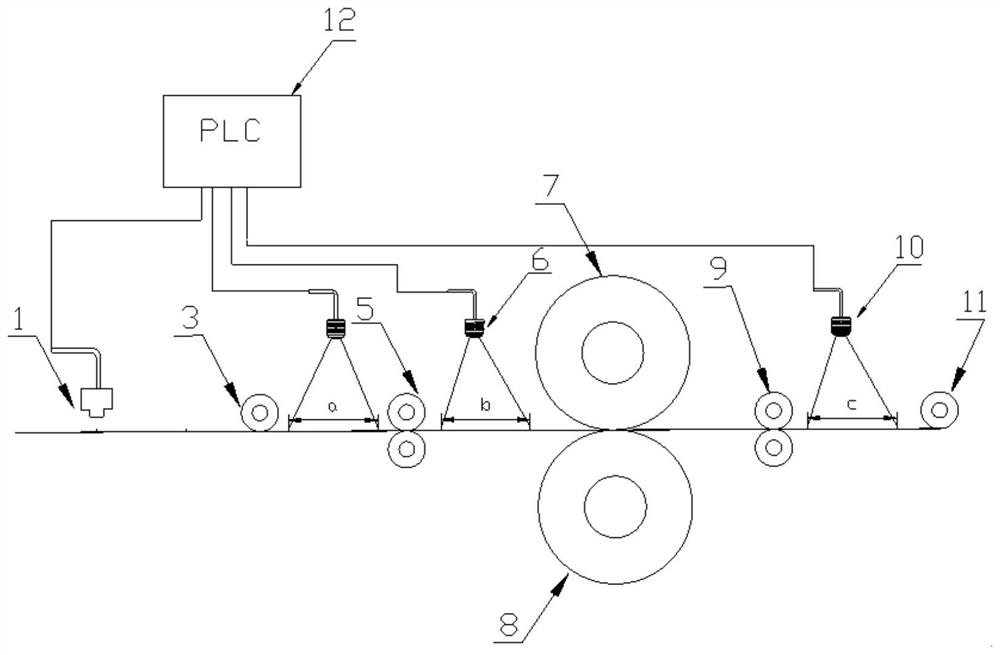

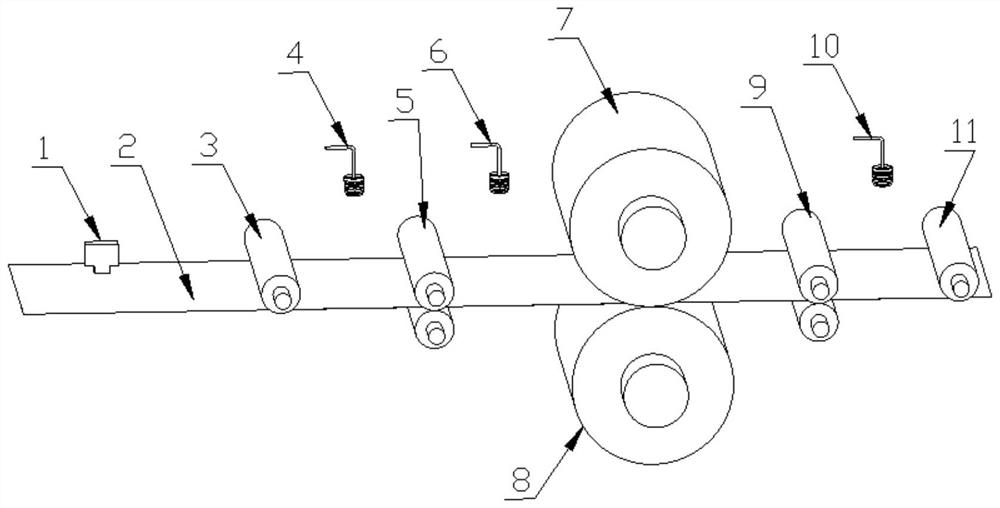

[0041] This embodiment is a pole piece extension consistency control system for realizing one-level closed-loop control of online extension. like figure 1 and figure 2As shown, PLC12 controls inkjet 1 to spray code to pole piece 2, denoted as inkjet 1, and uses the method of ink spraying as the sampling reference, while PLC12 controls the encoder to record the length of the pole piece 2 to travel, until the encoder records When the length of the running tape reaches the preset value L, a feedback signal is sent to the PLC12. At this time, the PLC12 controls the inkjet 1 to spray code to the pole piece 2, which is recorded as inkjet 2. The image information collected by the first camera 4, the second camera 6, and the third camera 10 respectively identifies the distance between the inkjet 1 and the inkjet 2 on the upper surface of the pole piece 2 to judge the extension state of the pole piece in real time, and the online measurement data is fed back to the PLC12, The on-lin...

Embodiment 2

[0044] The present embodiment is a pole piece extension consistency control method for realizing one-level closed-loop control of online extension, including the following steps:

[0045] S1 controls the ink jet 1 to print the ink on the upper surface of the pole piece 2, the pole piece 2 produces the ink jet 1, the pole piece 2 runs in the direction of the roller 3, and the encoder of the pole piece roll tension control system records the pole piece Chip coding position;

[0046] S2 When the distance between the travel distance of the pole piece and the coding position of the pole piece reaches the preset value L, the ink jet 1 is controlled to print the code on the upper surface of the pole piece 2 again, and the ink jet code is generated on the pole piece 2 2;

[0047] S3 The first camera 4 collects the image signal of the pole piece 2 passing between the front pass roller 3 and the front tension roller 5, and identifies the position information of the inkjet 1 and the ink...

Embodiment 3

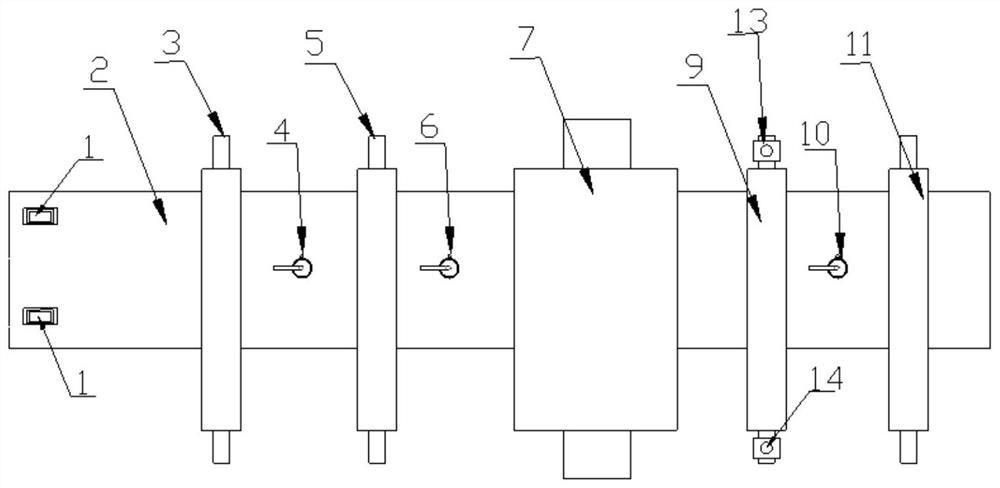

[0073] This embodiment is a pole piece extension consistency control system that realizes two-level closed-loop control of online extension. Compared with Embodiment 1, the linear motors provided in this embodiment include left linear motors respectively arranged on the left and right sides of the front tension roller 5 . 13. The right linear motor 14, the left linear motor 13 and the right linear motor 14 are respectively arranged on the left and right sides of the rear tension roller 9, such as Figure 4 As shown, the left linear motor 13 and the right linear motor 14 are respectively used to control the left and right tension of the tension roller, so as to adjust the elongation ratios of the left and right sides of the pole piece 2 respectively. The PLC12 compares the extension difference between the left and right sides of the foil, and feeds the signal to the linear motor through the control logic, adjusts the tension roller gap through the linear motor, changes the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com