Photocuring multi-material 3D printer

A 3D printer and photo-curing technology, applied in the field of 3D printing, can solve the problems of poor quality of finished products, complex structure of replacement mechanism, low efficiency of multi-material printing, etc., achieve automatic material change and automatic discharge, and improve printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

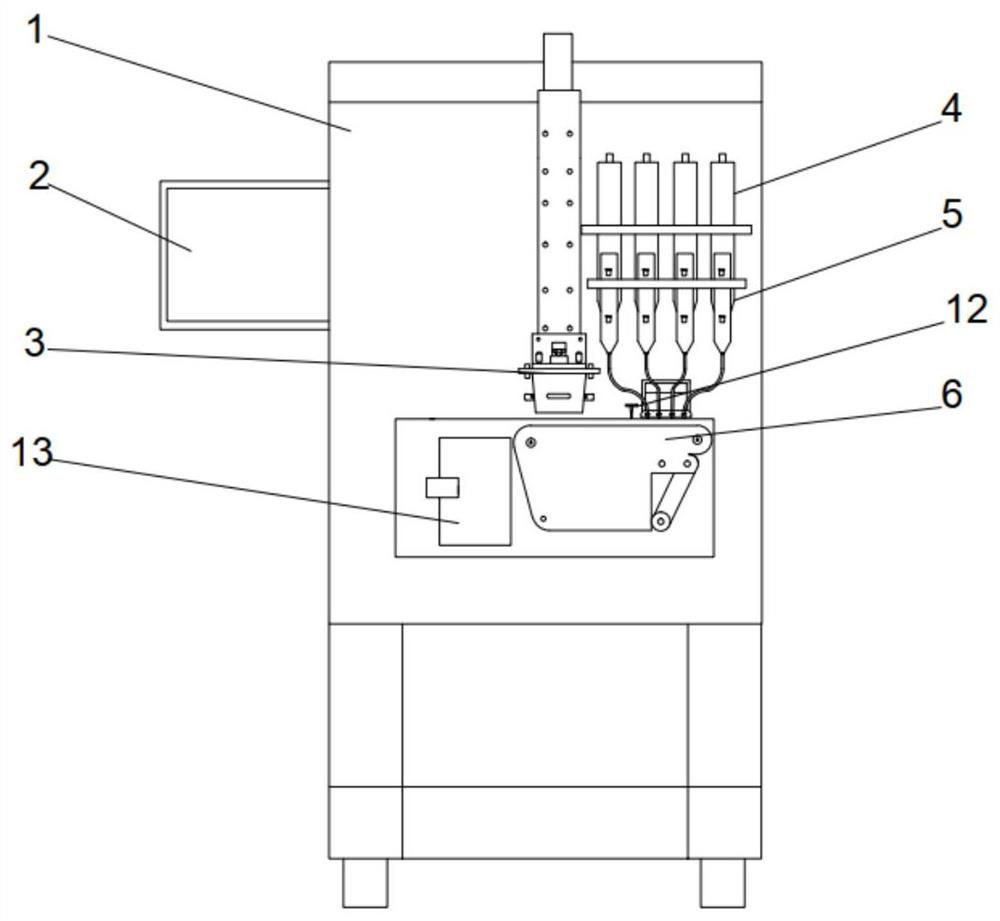

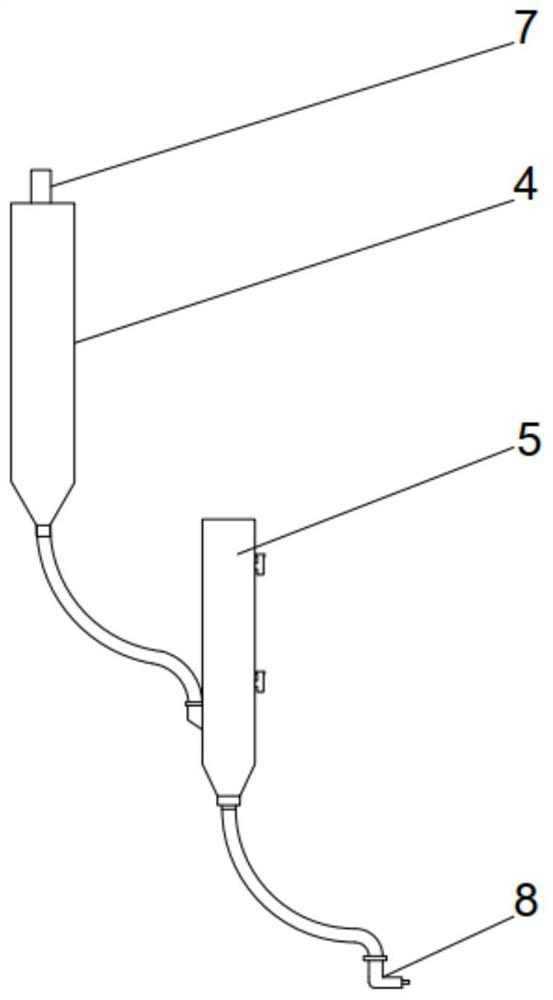

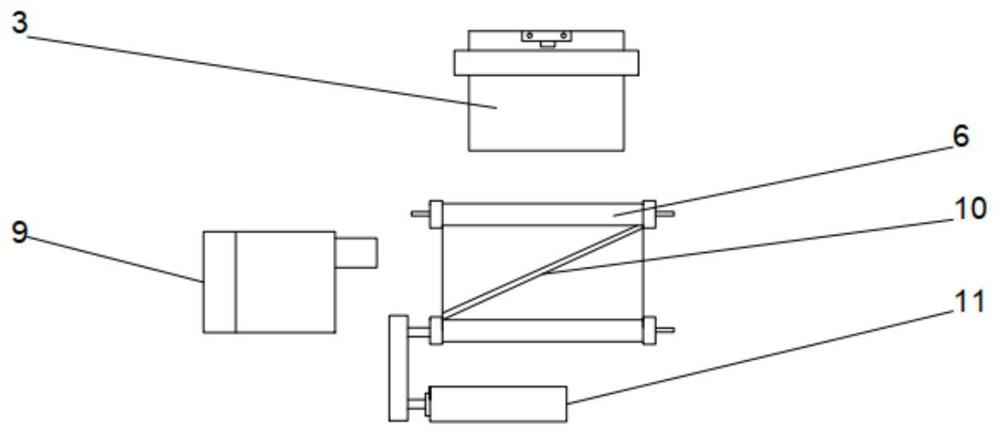

[0032] A light-curing multi-material 3D printer includes multiple sets of feeding modules, each set of feeding modules provides a printing material, and the printing materials can be of different materials, different components, and different colors, and each set of feeding modules works independently; The sleeve supply module includes at least one storage tank for storing printing material. The feeding module described therein adopts a casting process to cast the printing material to the printing area. The feeding module further comprises: a glue spraying valve connected with the storage tank for controlling the spraying of printing materials, and a casting nozzle connected with the glue spraying valve. A scraper is provided behind the casting nozzle; the glue spray valve is preferably a pneumatically controlled ejector pin type, and the ejector pin valve of the glue spray valve is opened or closed by controlling the on-off time of the air circuit. The front-end nozzle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com