Quick-cooling extrusion blowing device of polypropylene combined cover for plastic infusion container

An infusion container and rapid cooling technology, applied in the field of medical infusion container production, can solve problems such as increased cost, deformation of finished products, difficult disassembly and maintenance, etc., to avoid deformation of finished products and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

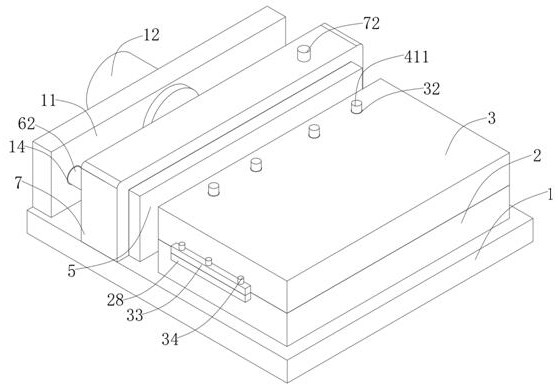

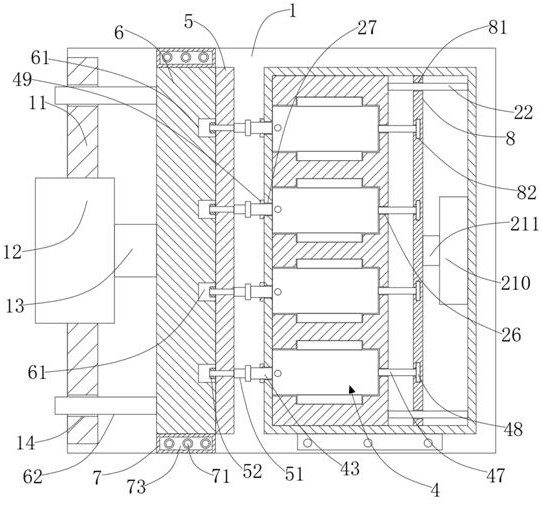

see figure 2 and Figure 5 , the top surface of the worktable 1 is away from the bottom surface of the lower box 2 and the top surface of one end is vertically fixed to the fixed plate 11. Two first guide sliding holes 14 are horizontally opened at both ends of the fixed plate 11. The two first guide sliding holes 14 slide sleeves respectively. Two first guide slide bars 62 are connected, and one end of the two first guide slide bars 62 close to the lower box body 2 is fixedly connected to the movable template 6 .

[0021] see Figure 1-2, the top surface of the worktable 1 is located outside the movable template 6 and is fixedly connected to the cooling cover 7, the cooling cover 7 is provided with a cooling liquid cavity 73, the cooling liquid cavity 73 is fixedly connected to the cooling liquid pipe 71, and the top surface of the cooling cover 7 is fixedly connected to the liquid pipe 72. The connecting liquid pipe 72 is connected to the cold liquid pipe 71. When in use, ...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com