Front and back side synchronous printing equipment

A simultaneous printing and two-sided technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of ink contamination on other equipment, affecting printing quality, and damage to the printing surface, so as to avoid material scrapping, avoid printing unclear, Avoid the effect of ink drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

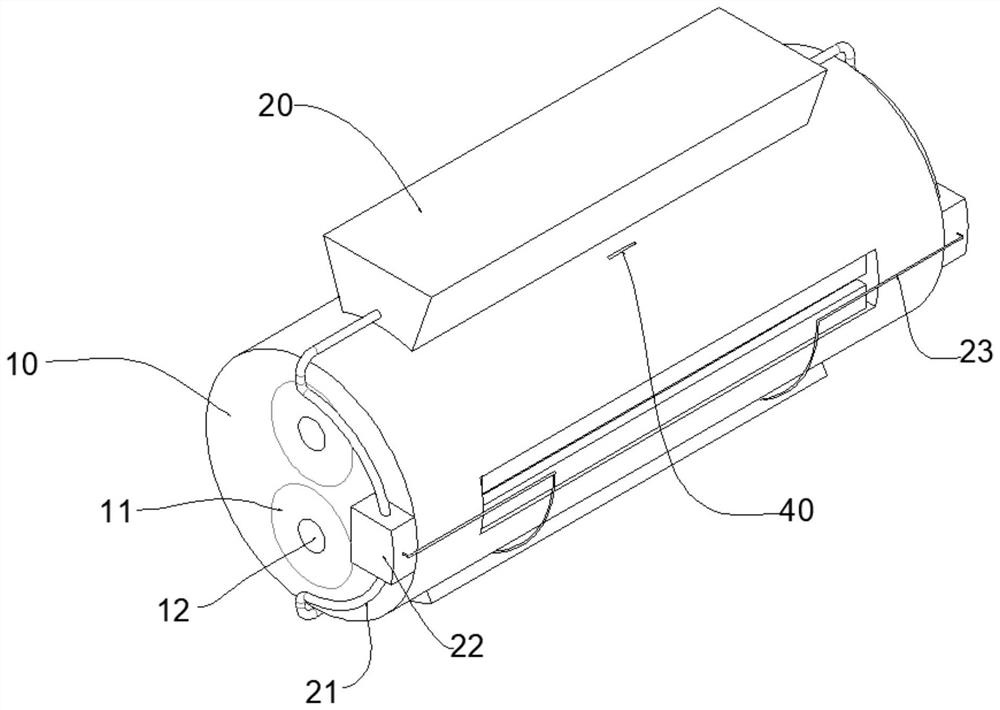

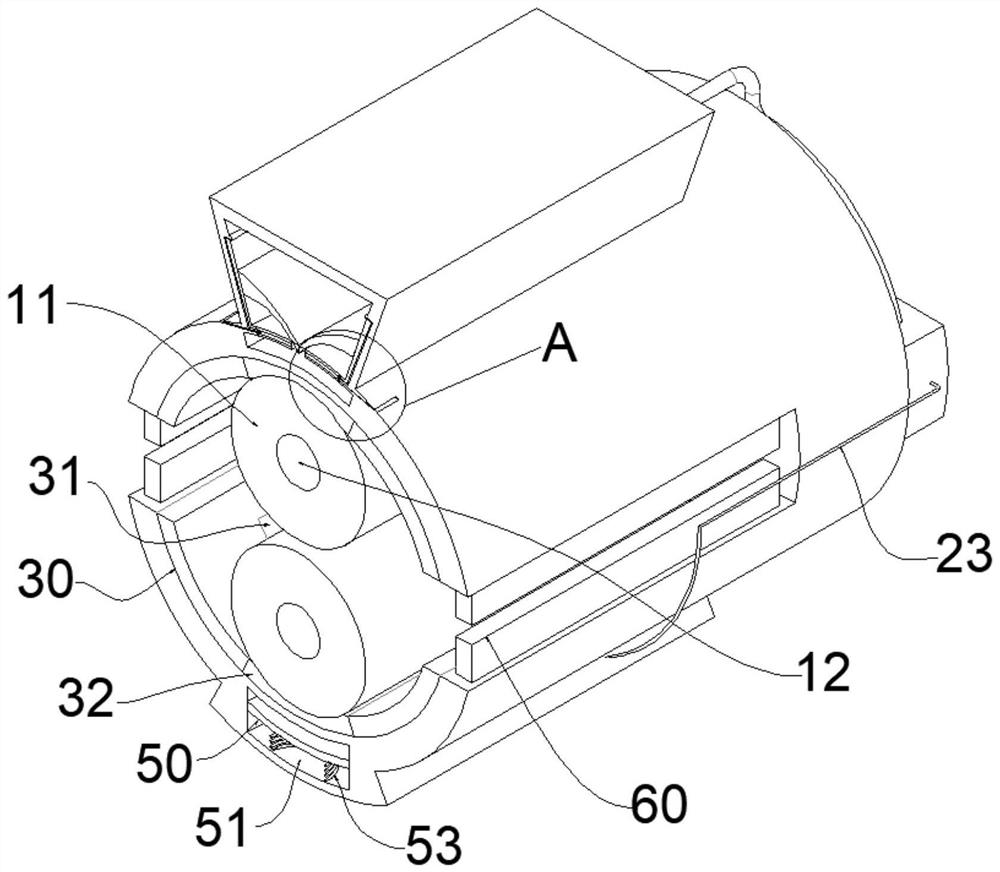

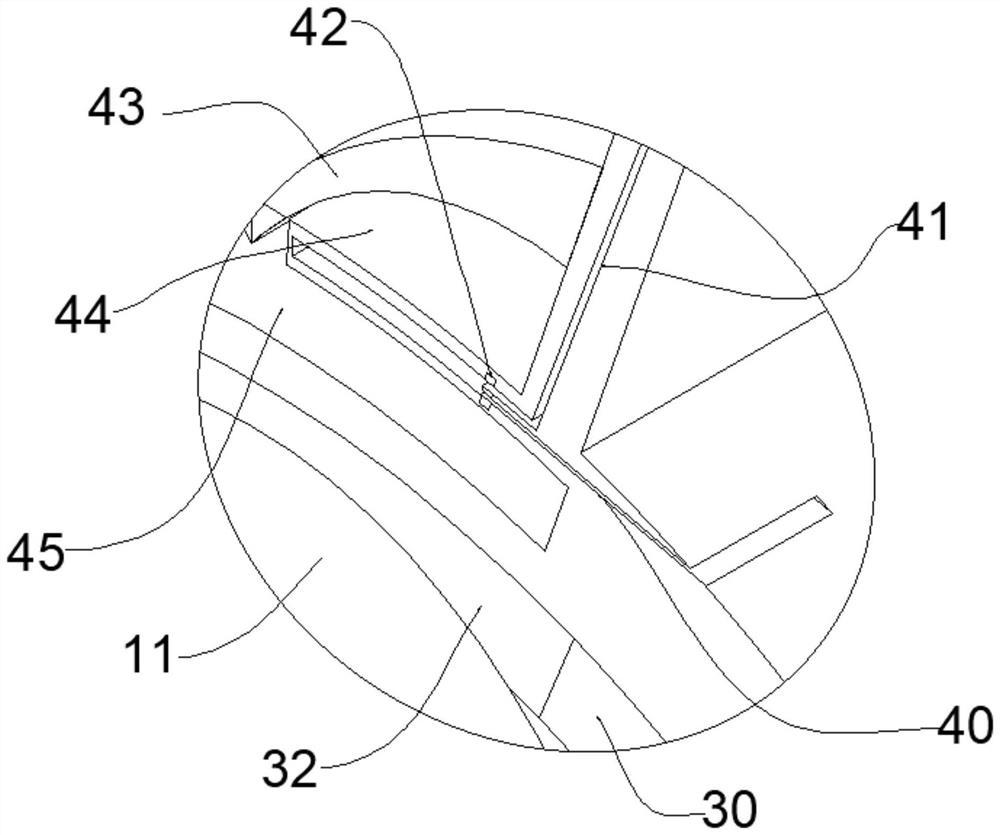

see Figure 1-5 , the present invention provides a technical solution: a positive and negative two-sided synchronous printing equipment, including a thermal insulation shell 10, a printing cavity 13, a pair of printing parts, a supply part, a thermal insulation layer 30 and a pair of ink coatings 32; the printing cavity 13 is provided with In the thermal insulation shell 10, rectangular through holes are formed through the thermal insulation shell 10 on both sides of the printing cavity 13 in the horizontal direction; The wheel 11 and the printing shaft 12, the printing wheel 11 and the printing shaft 12 are fixedly connected, the two ends of the printing wheel 11 are rotatably connected with the inner wall of the printing cavity 13, and the two ends of the printing shaft 12 extend through the printing cavity 13 to the outside of the heat preservation shell 10 and are connected with the inner wall of the printing cavity 13. The external drive equipment is connected; the ink coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com